Energy-saving and environment-friendly wall cold bridge breaking installation structure for constructional engineering

An energy saving, environmental protection, construction engineering technology, applied in building components, building structures, building insulation materials, etc., can solve the problems of cumbersome fixing, deformation and displacement of insulation materials, and the inability to combine fixed structures and waterproof structures organically.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

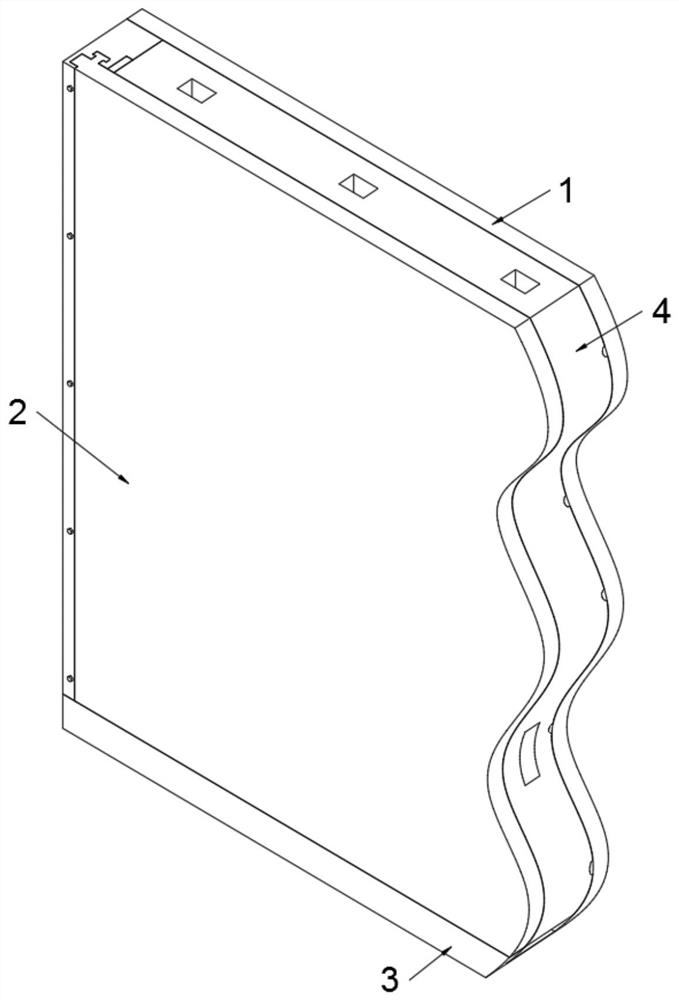

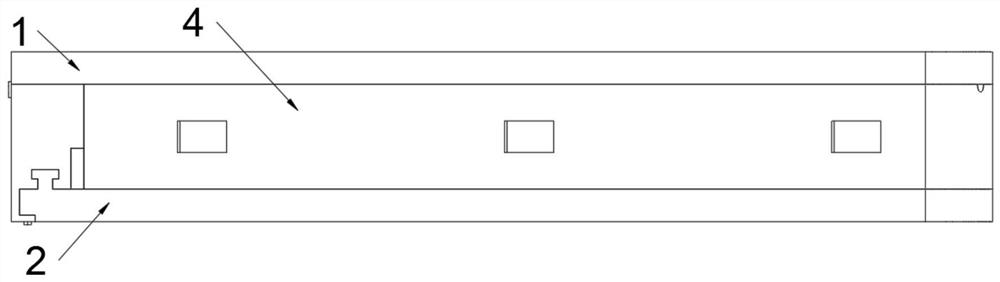

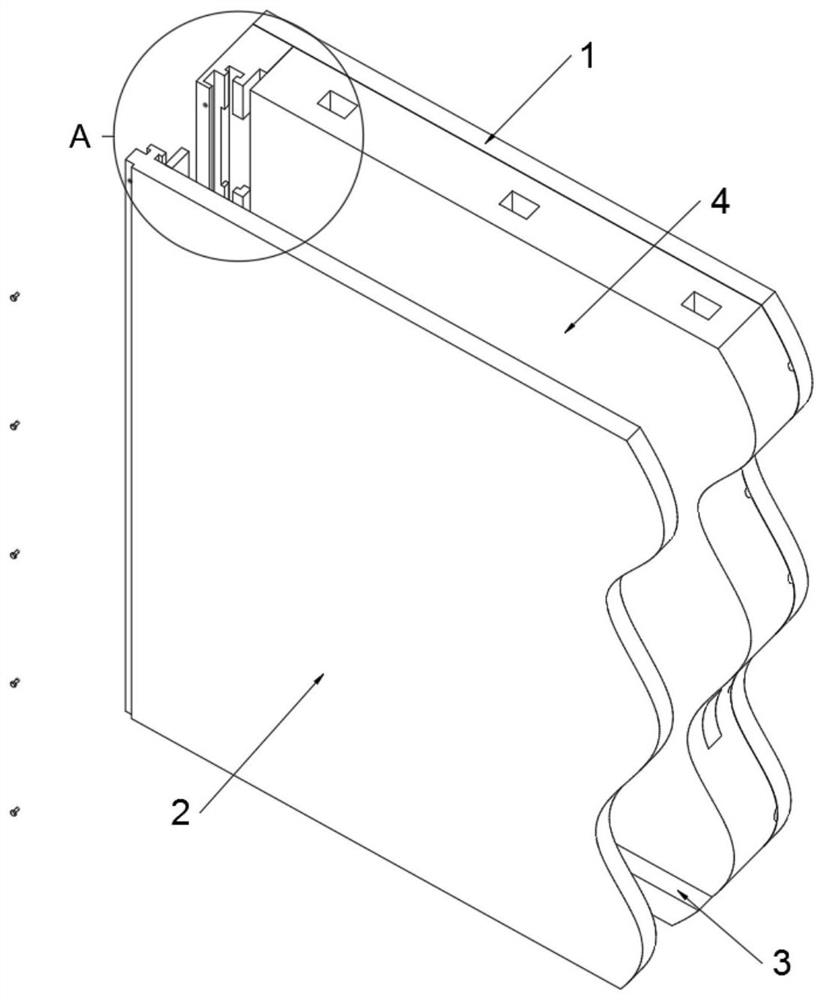

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The invention provides an energy-saving and environment-friendly wall body cold bridge installation structure for construction engineering, which includes a first color plate 1; a second color plate 2 is connected to the first color plate 1, and the first color plate 1 and the second color plate 2 is plugged with insulation material 4, and the bottom end of the first color plate 1 is welded with a base 3; refer to Figure 4 , the first color plate 1 includes a groove A103, a groove A103 is opened on the first color plate 1, and the groove A103 is a rectangular groove-like structure; the second color plate 2 includes a rectangular plate 202, and the second color plate 2 A rectangular plate 202 is welded, and when the first color plate 1 and the second color plate 2 are plugged, the rectangular plate 202 is in contact with the groove A103, and when the rectangular plate 202 is plugged into the groove A103, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com