A core tube concrete wall folding formwork and its application method

A technology of concrete wall and core tube, applied in the direction of formwork/formwork member, formwork/formwork/work frame, formwork/formwork/work frame connection, etc. Reasonable path, improve construction efficiency, and improve the effect of industrialization level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

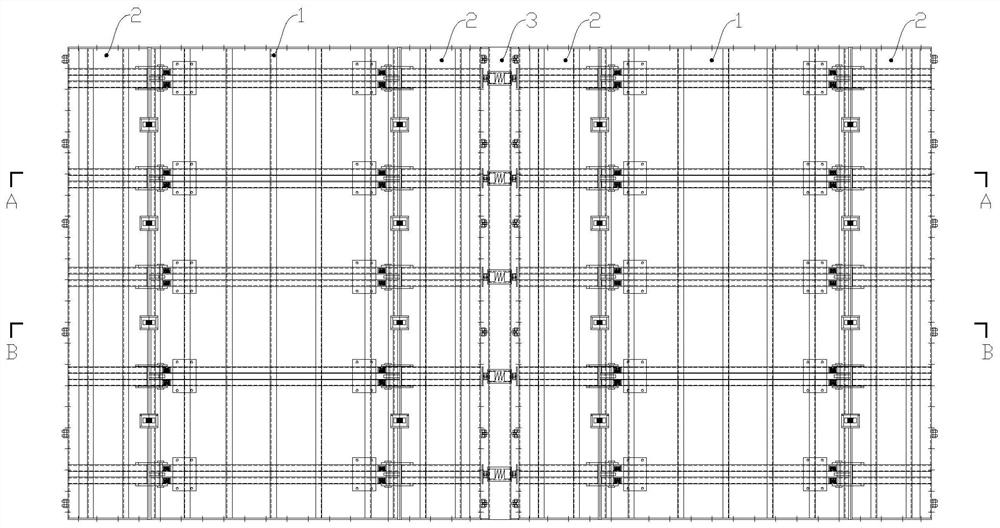

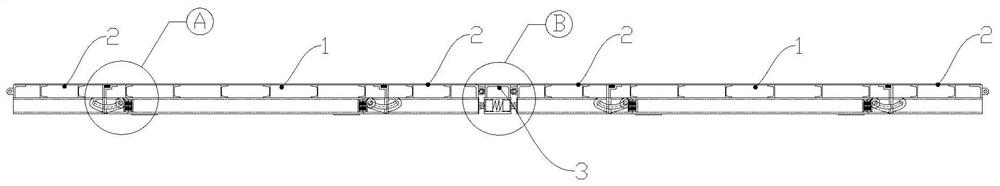

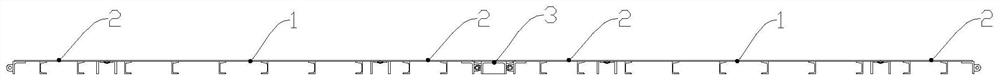

[0060] Such as Figure 1 to Figure 3 and Figure 16 and Figure 17 As shown, a core tube concrete wall folding formwork provided in this embodiment includes several flat forms 1 , rotary forms 2 , joint forms 3 and formwork push-pull devices 4 . A flat mold 1 and rotary molds 2 arranged on both sides of the flat mold form a group of opening and closing mold units, and the flat mold is hinged to the rotary molds on both sides; two groups of adjacent opening and closing mold units are connected by a joint mold 3, The joint mold is hinged with the rotary molds on both sides.

[0061] The template push-pull device 4 includes a telescopic end, and the telescopic end is fixedly connected to the back of the flat mold 1. The template push-pull device 4 is used to drive the flat mold 1 to reciprocate perpendicular to the wall surface 5, and the flat mold 4 drives the rotary mold 2 Rotate and move with the flat mold, the rotary mold 2 on both sides drives the joint mold 3 to approach...

Embodiment 2

[0070] This embodiment provides a method for using the folded formwork for the concrete wall of the core tube. Figure 1 to Figure 19 The method of use is further described. The method of use includes the following steps:

[0071] S1. Set the formwork push-pull device on the formwork; after the wall reinforcement binding of the building structure is completed, set a number of flat forms, rotary forms and continuous forms on both sides of the wall, two rotary forms and a flat form form a set of opening The mold clamping unit, the two opening and closing mold units are connected through the joint mold, and the flat mold is connected with the template push-pull device to form an overall folded template; all the template push-pull devices connected with the flat mold work together, and the telescopic rod is stretched out and Push the folding template to be in the mold closing state, such as Figure 18 shown.

[0072] Specifically, the connecting plate of the rotating shaft of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com