Automatic coal sliding hole anti-blocking device and using method

A technology for slipping coal holes and preventing blockages, applied in the field of mining machinery, can solve the problems of ineffective manual dredging, harsh construction environment, and difficult construction, so as to achieve unmanned supervision and management, avoid serious safety accidents, and have repeatability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

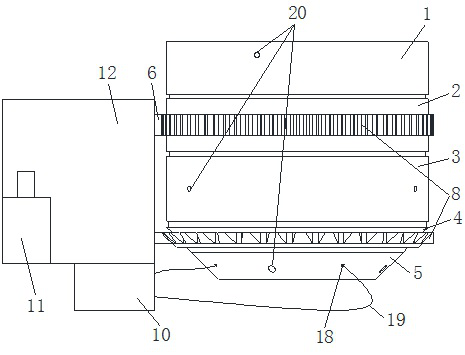

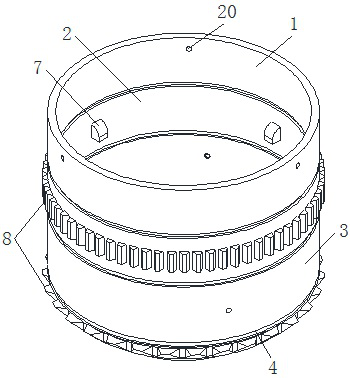

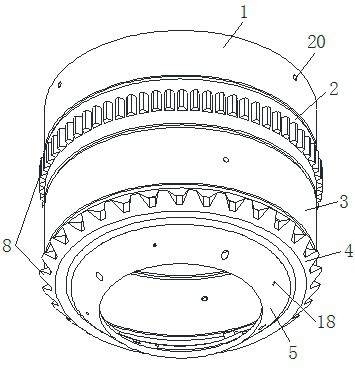

[0026] Such as Figure 1-5 As shown, an automatic coal mine anti-blocking device includes a control assembly and an anti-blocking assembly, and the anti-blocking assembly includes a first sleeve 1, a first drum 2, a second sleeve 3, The second roller 4 is fixedly connected to the cylinder 5, the bottom end of the first sleeve 1 is rotatably connected to the top end of the first roller 2, the bottom end of the first roller 2 is rotatably connected to the top end of the second sleeve 3, The bottom end of the second sleeve 3 is rotatably connected to the top end of the second roller 4, and the bottom end of the second roller 4 is rotatably connected to the top end of the fixed connection cylinder 5. The first roller 2 and the second roller 4 Gear teeth 8 are welded on the outer sidewall of the cylinder, and agitation protrusions 7 are welded on the inner sidewall, and a gravity sensor 9 is fixedly installed on the inner sidewall of the fixed connection cylinder 5;

[0027] The c...

Embodiment 2

[0033] Such as Figure 1-5As shown, an automatic coal mine anti-blocking device includes a control assembly and an anti-blocking assembly, and the anti-blocking assembly includes a first sleeve 1, a first drum 2, a second sleeve 3, The second roller 4 is fixedly connected to the cylinder 5, the bottom end of the first sleeve 1 is rotatably connected to the top end of the first roller 2, the bottom end of the first roller 2 is rotatably connected to the top end of the second sleeve 3, The bottom end of the second sleeve 3 is rotatably connected to the top end of the second roller 4, and the bottom end of the second roller 4 is rotatably connected to the top end of the fixed connection cylinder 5. The first roller 2 and the second roller 4 Gear teeth 8 are welded on the outer sidewall of the cylinder, and agitation protrusions 7 are welded on the inner sidewall, and a gravity sensor 9 is fixedly installed on the inner sidewall of the fixed connection cylinder 5;

[0034] The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com