Novel cross-flow fan impeller and assembling method thereof

A cross-flow fan and impeller technology, applied in the field of new cross-flow fan impeller and its assembly, can solve the problems of high wind speed, low wind speed, high noise, etc., and achieve the effects of high wind speed, increased wind interception area, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

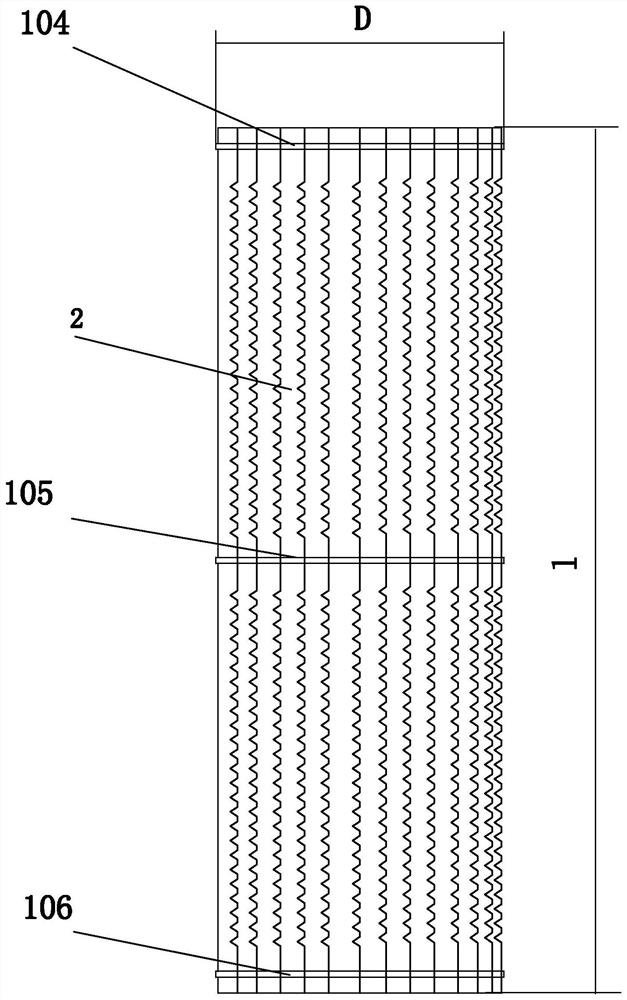

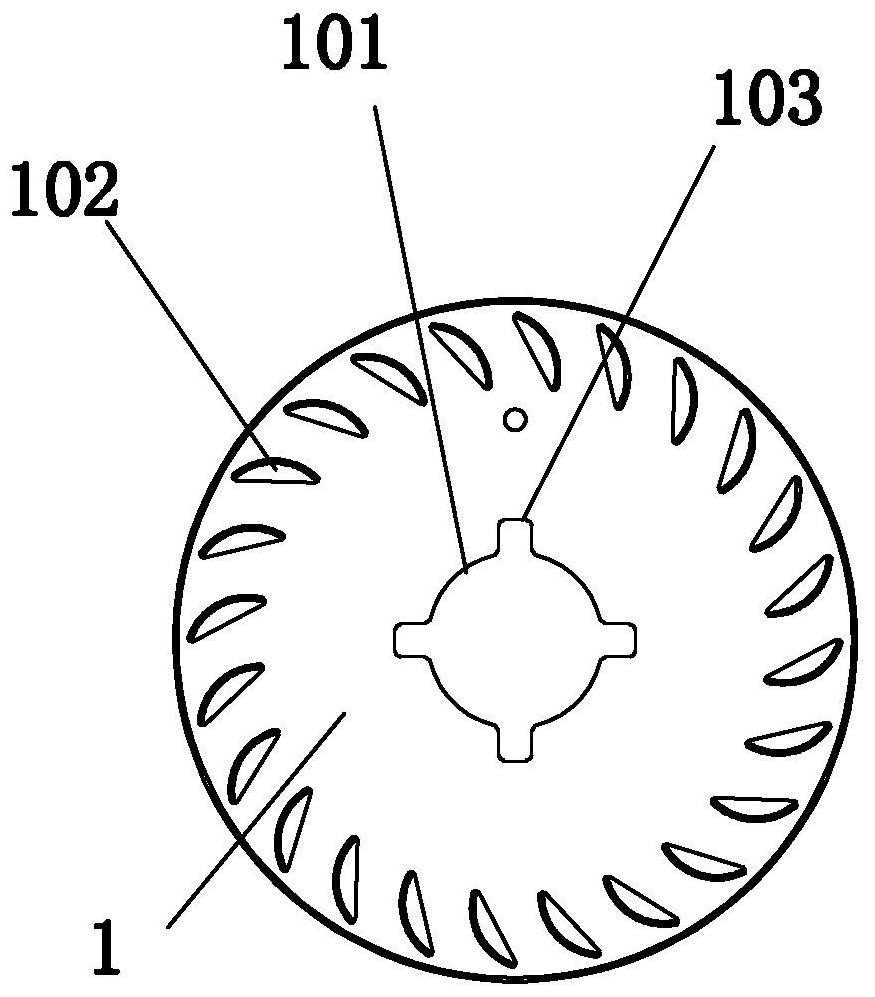

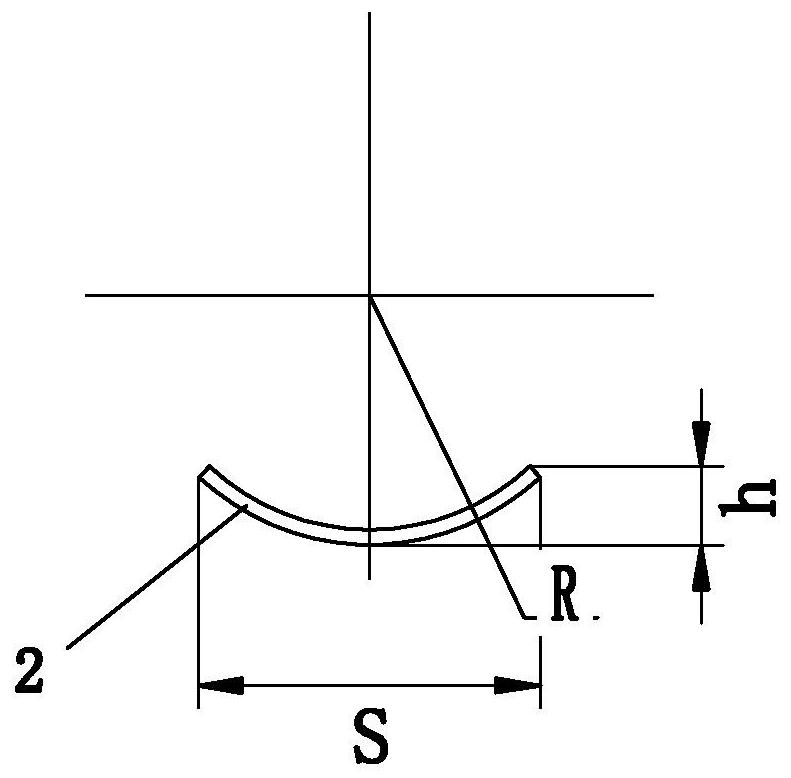

[0078] Such as Figure 1 to Figure 19 As shown, the new cross-flow fan impeller, such as Figure 1 to Figure 3 As shown, it is a barrel-shaped wheel, referred to as the impeller, including three fixed disks 1 and fan blades. The number of slot holes 102 is equal to the number of blades 2; a reference hole 101 is arranged in the middle of the fixed disk 1, and four key grooves 103 are evenly arranged around the periphery of the reference hole 101; The slotted hole, the blade 2 is a rectangular strip, installed in the blade fixing slot 102, and connects all the fixed disks 1 together; the cross section of the blade 2 is an arc section, and the width S of the arc section of the blade 2 is 7.7mm , the height h of the arc section of the blade 2 is 1.8 mm, and the arc radius R of the arc section of the blade 2 is 5.5 mm;

[0079] Such as Figure 4 to Figure 9 As shown, the blade 2 is provided with a notch 201 on the outer side, and the blade 2 between every two fixed disks 1 cont...

Embodiment 2

[0124] The notch 201 is a concave notch 201 .

[0125] Such as figure 1 with figure 2 As shown, the fixed disk 1 is a front fixed disk 104 , a middle fixed disk 105 and a rear fixed disk 106 .

[0126] Such as Figure 8 As shown, the upper convex edge 202 and the lower bottom edge 203 of the concave notch 201 of the concave notch 201 have the same length.

[0127] The equipment used is a high-speed punching machine, a concave notch 201 blade 2 stamping dies 7 .

[0128] The shape of the stamping die for the concave-shaped notch blade corresponds to the shape of the concave-shaped notch blade.

[0129] The rest are the same as embodiment 1.

Embodiment 3

[0131] The notch 201 is a wavy notch 201 .

[0132] Such as figure 1 with figure 2 As shown, the fixed disk 1 is a front fixed disk 104 , a middle fixed disk 105 and a rear fixed disk 106 .

[0133] Such as Figure 9 As shown, the shape and size of the upper wavy line 204 and the lower wavy line 205 of the wavy gap 201 are equal, and the upper wavy line 204 and the lower wavy line 205 are opposite in direction, connected to each other, and intersected.

[0134] The equipment used is a high-speed punching machine, a wave-shaped notch 201 blade 2 stamping die 7.

[0135] The shape of the stamping die of the wavy notch blade corresponds to that of the wavy notch blade.

[0136] The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com