Pressurizing cylinder mechanism

A technology of booster cylinder and cylinder, which is applied in mechanical equipment, fluid pressure converter, fluid pressure actuating device, etc., can solve the problem of large installation space, and achieve the effect of good booster effect, reliable use and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

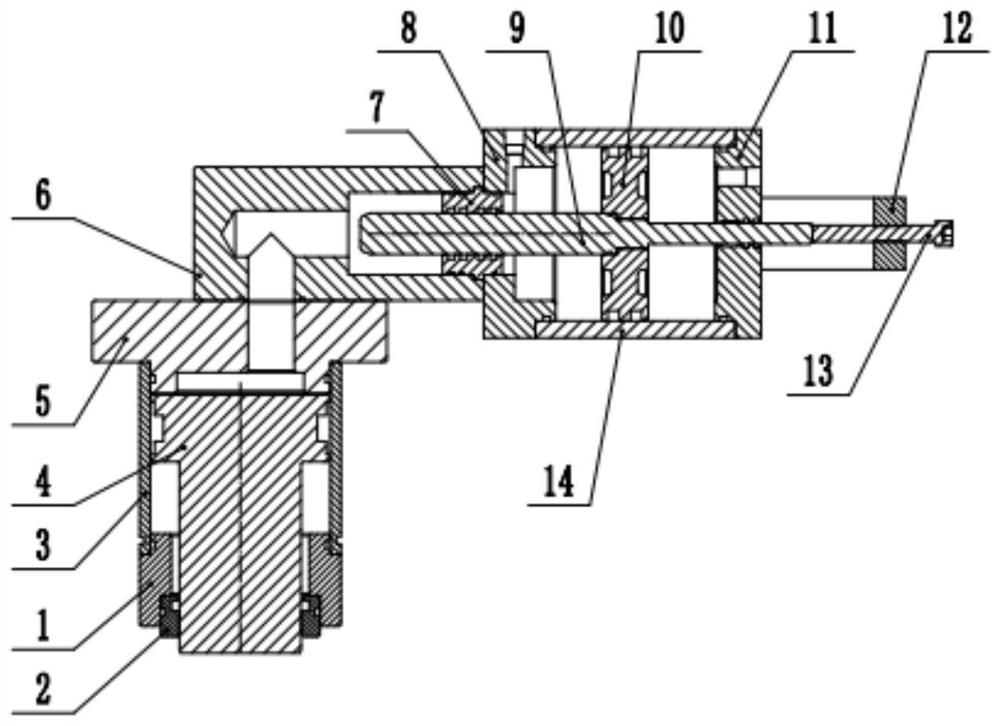

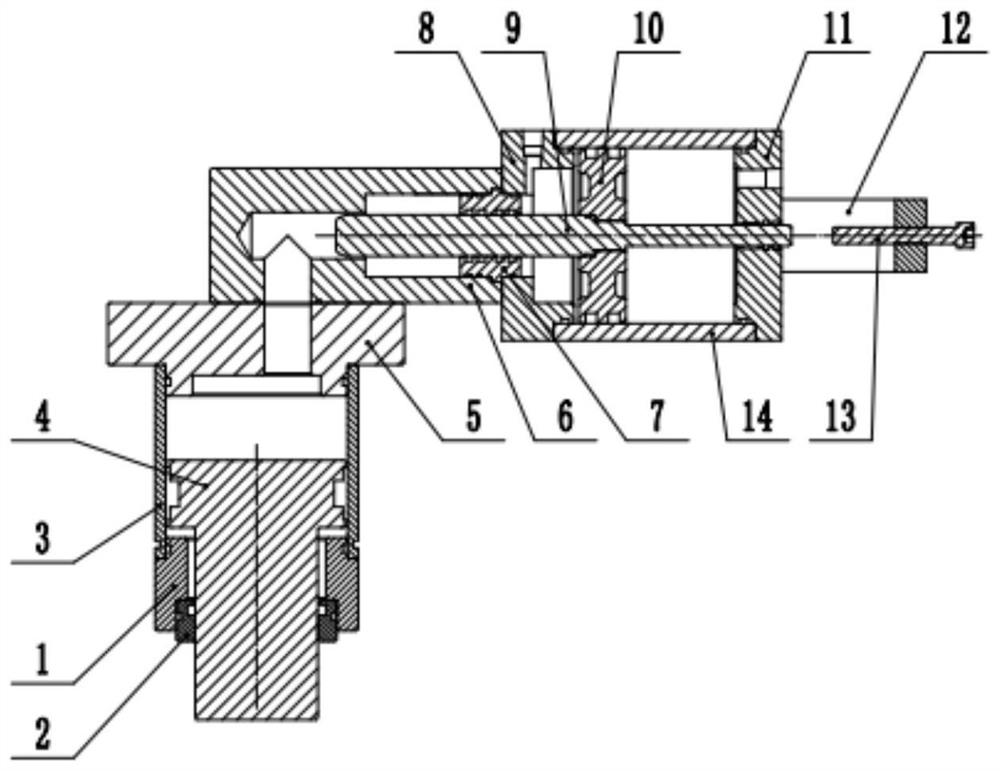

[0014] Such as Figure 1-2 As shown, a booster cylinder mechanism includes a booster cylinder 3, one end of the booster cylinder 3 is provided with a booster cover 1, a booster cylinder 3 is provided with a booster piston rod 4, and a booster piston rod 4 The end of the booster cylinder 3 passes through the booster cover 1, the booster cover 1 is provided with a sealing steel sleeve 2 matching the booster piston rod 4, the other end of the booster cylinder 3 is provided with a middle cylinder head 5, and the middle cylinder The cover 5 is provided with a penetrating oil hole, and the middle cylinder head 5 is provided with a pressurized flange 6, and the pressurized flange 6 is provided with an L-shaped through hole that communicates with the oil hole at one end. The flange 6 is provided with an oil inlet and outlet hole through the L-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com