Coal economizer water temperature adjusting system for denitration input in unit starting process

A technology for unit startup and water temperature adjustment, which is applied in the control system, liquid degassing, steam superheating, etc. It can solve the problems of low stable combustion load, failure to operate normally, and excessive nitrogen oxide emissions from boilers, and achieve effective adjustment and shortening. The effect of start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

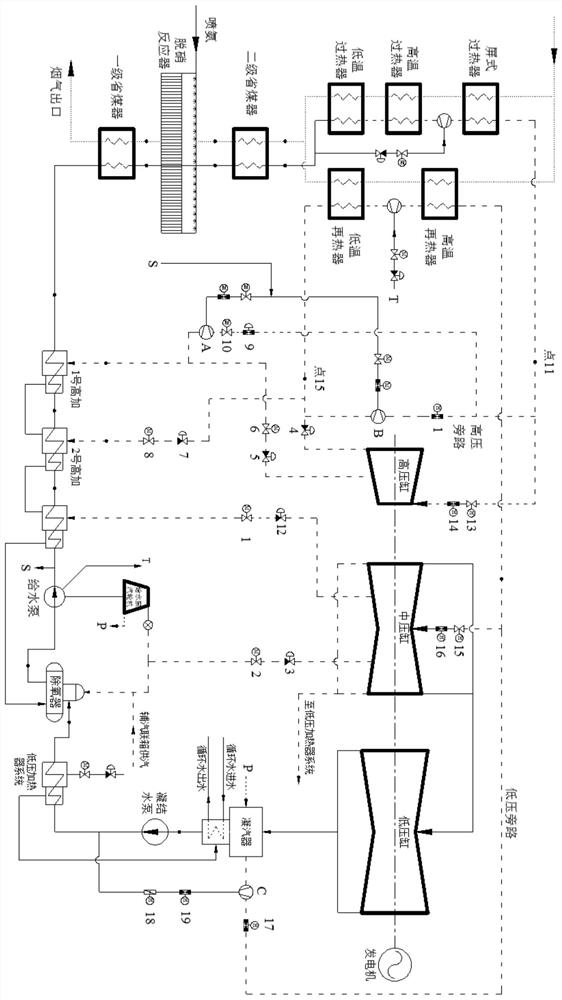

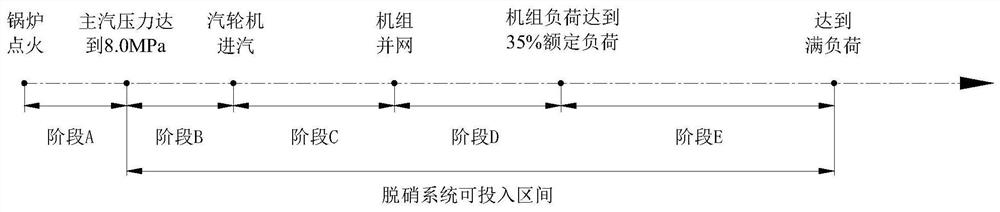

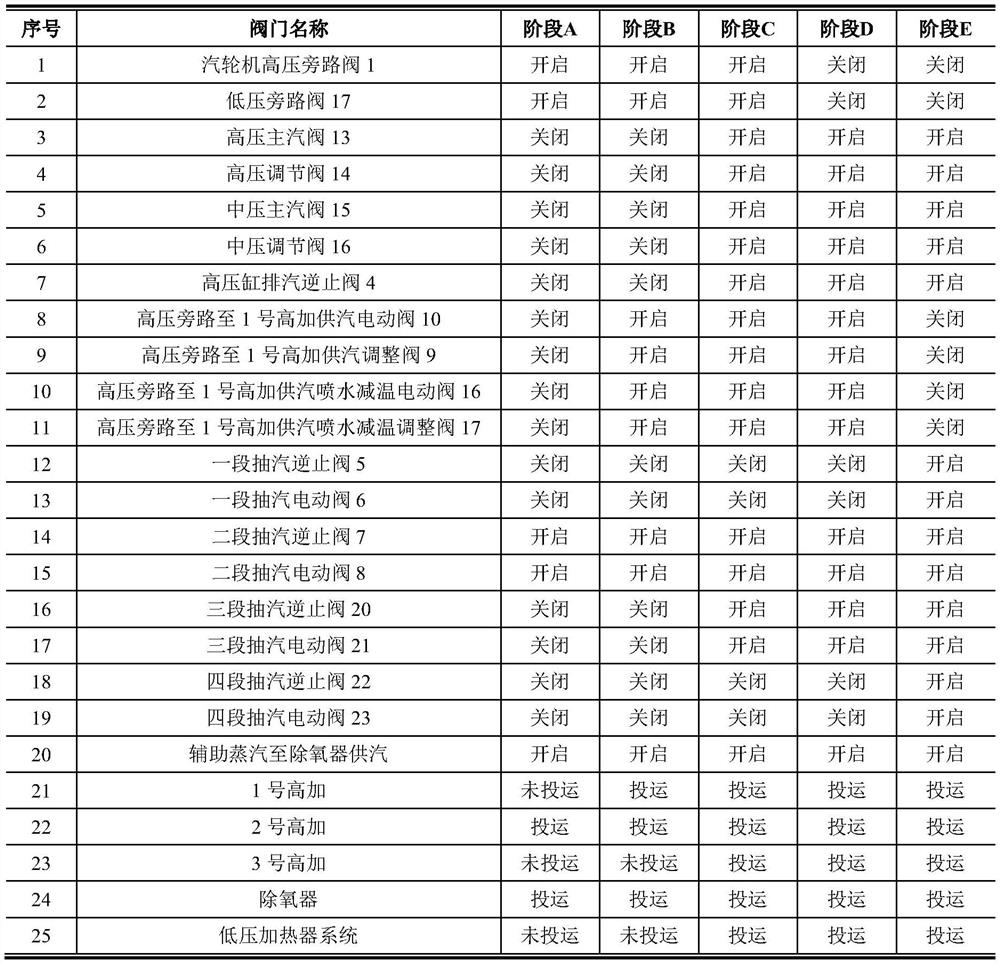

[0023] refer to figure 1 , the economizer water temperature adjustment system for denitrification input in the unit start-up process according to the present invention includes a panel superheater, a high-pressure main steam valve 13, a high-pressure regulating valve 14, a high-pressure cylinder, a high-pressure bypass, a low-temperature reheater, and a regulating valve 9 , Second electric valve 10, No. 1 high-pressure heater, high-pressure cylinder exhaust check valve 4, low-temperature reheater, second-stage extraction check valve 7, first electric valve 8, No. 2 high-pressure heater, first-stage extraction Steam check valve 5, one-stage steam extraction electric valve 6, high-temperature reheater, high-pressure regulating valve 14, medium-pressure main steam valve 15, medium-pressure cylinder, low-pressure bypass, condenser, three-stage steam extraction check valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com