System and method for simultaneous detection of three-dimensional surface and thickness distribution of transparent materials

A transparent material and three-dimensional surface technology, applied in image analysis, measuring devices, image enhancement, etc., can solve the problems of uncertain incident angle and azimuth angle, inability to detect thickness distribution, and influence of three-dimensional surface detection, etc., and achieve strong anti-noise performance , simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

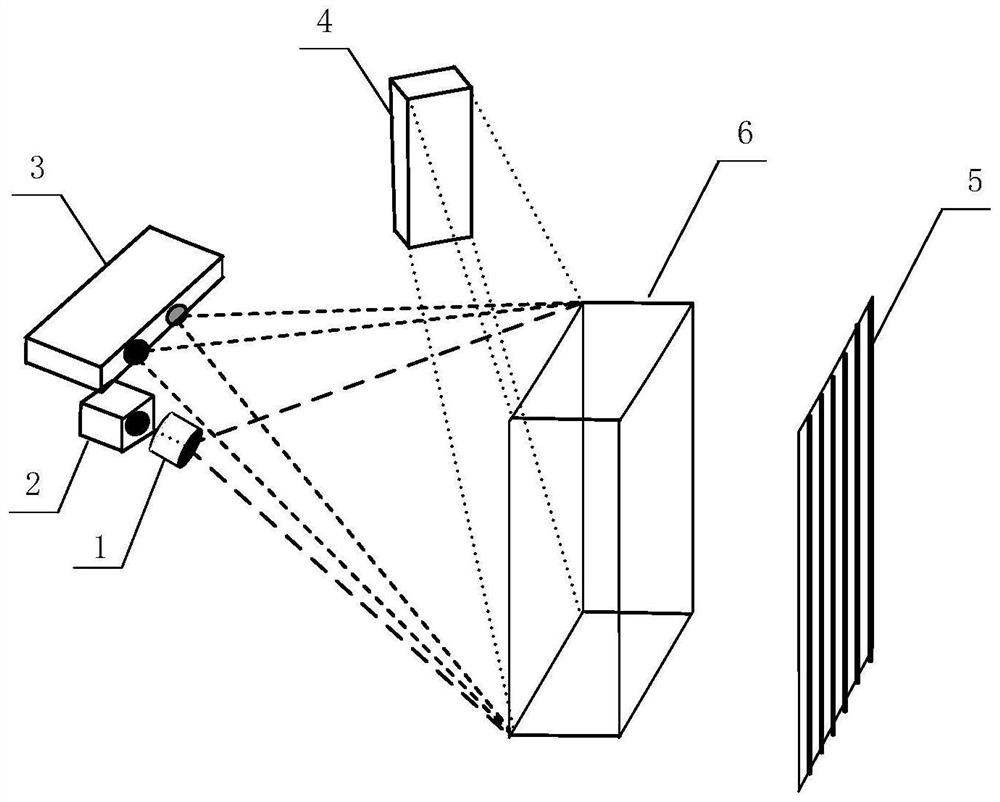

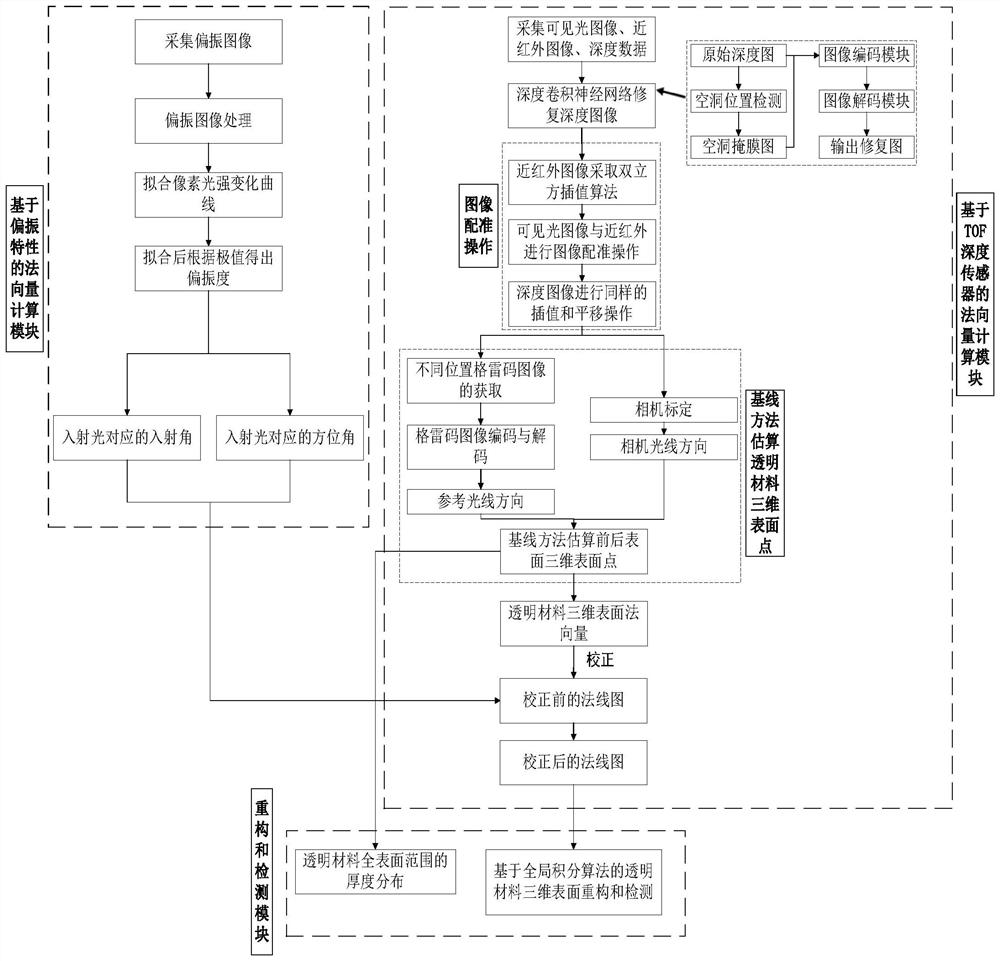

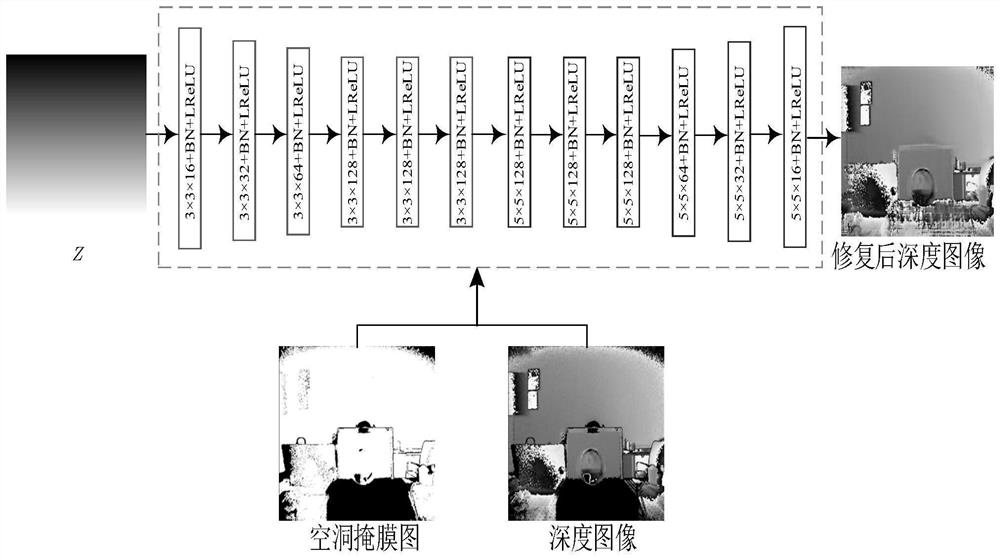

[0066] The simultaneous detection system for the three-dimensional surface and thickness distribution of transparent materials includes an image acquisition module, a depth sensor, a surface light source 4, a reference panel 5, a transparent material 6 and a control unit. The image acquisition module includes an industrial camera 2 and a rotatable linear polarizer 1 with a scale; the linear polarizer 1 is placed in front of the lens of the industrial camera 2 . The depth sensor is a TOF depth sensor 3 .

[0067] The industrial camera 2 and the TOF depth sensor 3 are placed at the same height on the same side of the reference panel 5; the transparent material with a large area and a large thickness is 75mm; the transparent material such as Figure 4 As shown, it is an object made of transparent glass with a large area and a large thickness.

[0068] The linear polarizer 1 is placed in front of the lens of the industrial camera 2, and is used in conjunction with the industrial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com