Yarn Detection Method Based on Image Morphology Recognition

A technology of image morphology and detection method, which is applied in the inspection of textile materials, textiles and papermaking, knitting, etc., can solve the problems of easy interference, large gain of amplifier circuit, and small detection area, and achieves the effect of simple principle and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Now in conjunction with accompanying drawing, the present invention will be further described:

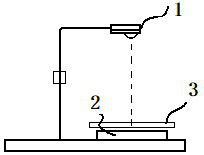

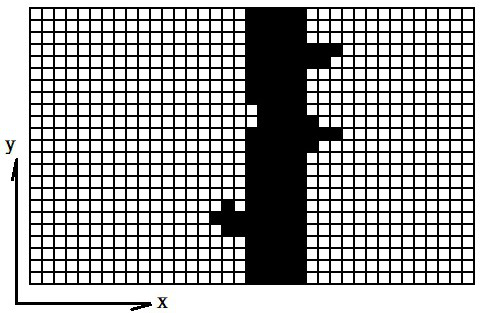

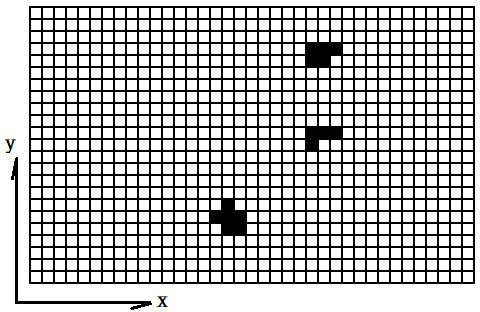

[0018] refer to figure 1 -3, the yarn detection method based on image form recognition, a U-shaped housing, and an electronic control device arranged inside the housing, the electronic control device includes a power supply circuit for supplying power, and processing for computing device, an infrared emitting unit 1 and an image sensor 2 connected to the processor, and an infrared filter 3 is arranged on the image sensor 2 .

[0019] The power supply circuit converts the input power level and stabilizes the voltage to provide power for other circuits.

[0020] The image sensor 2 is configured as a CCD linear image sensor or a CMOS linear image sensor sensitive to infrared rays, and the processor can read image data as required.

[0021] The infrared filter 3 can filter out light other than infrared light, which can greatly improve environmental adaptability and avoid inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com