Bobbin detector

A detector and coil paper technology, applied in the field of packaging, can solve the problems of discontinuous paper supply, product loss, packaging accidents, etc. Effect

Inactive Publication Date: 2011-01-05

安徽科达自动化集团股份有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the high-speed production lines of various industries in my country, the paper feeding speed of the packaging equipment paper feeding system is generally 600 m / min, and the paper feeding speed of some more advanced packaging equipment can reach 1600 m / min. Paper discontinuity, interruption, dislocation, breakage, etc., if not immediately found and shut down, packaging accidents will occur, resulting in product loss

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

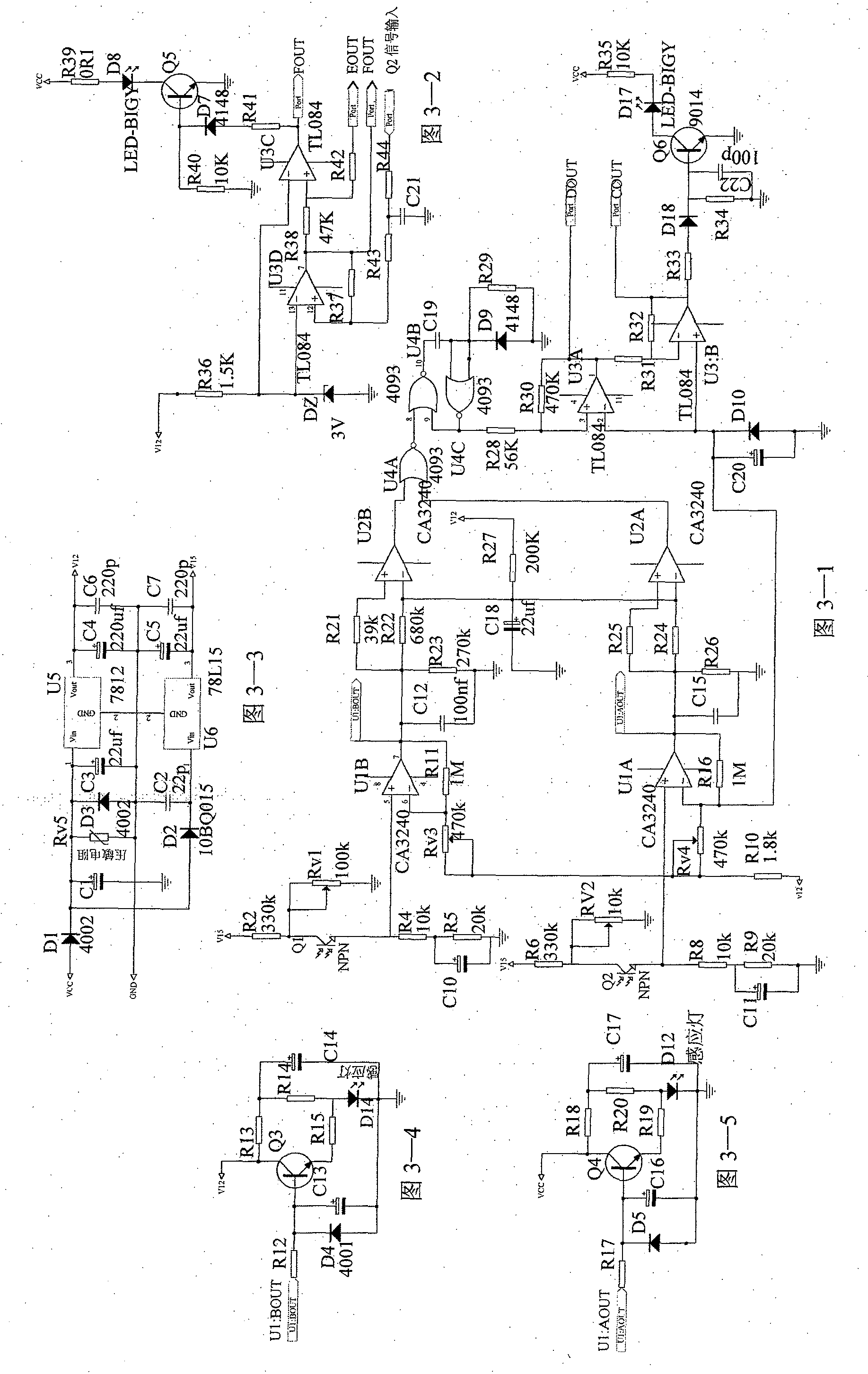

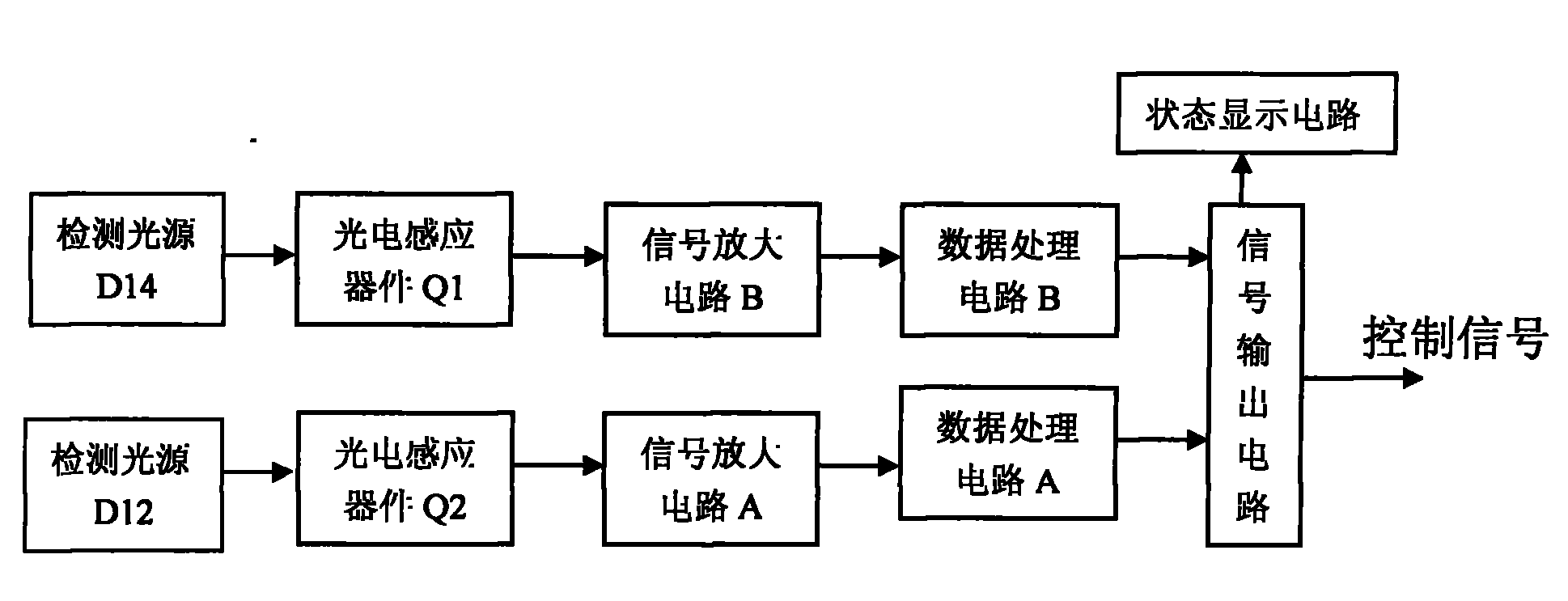

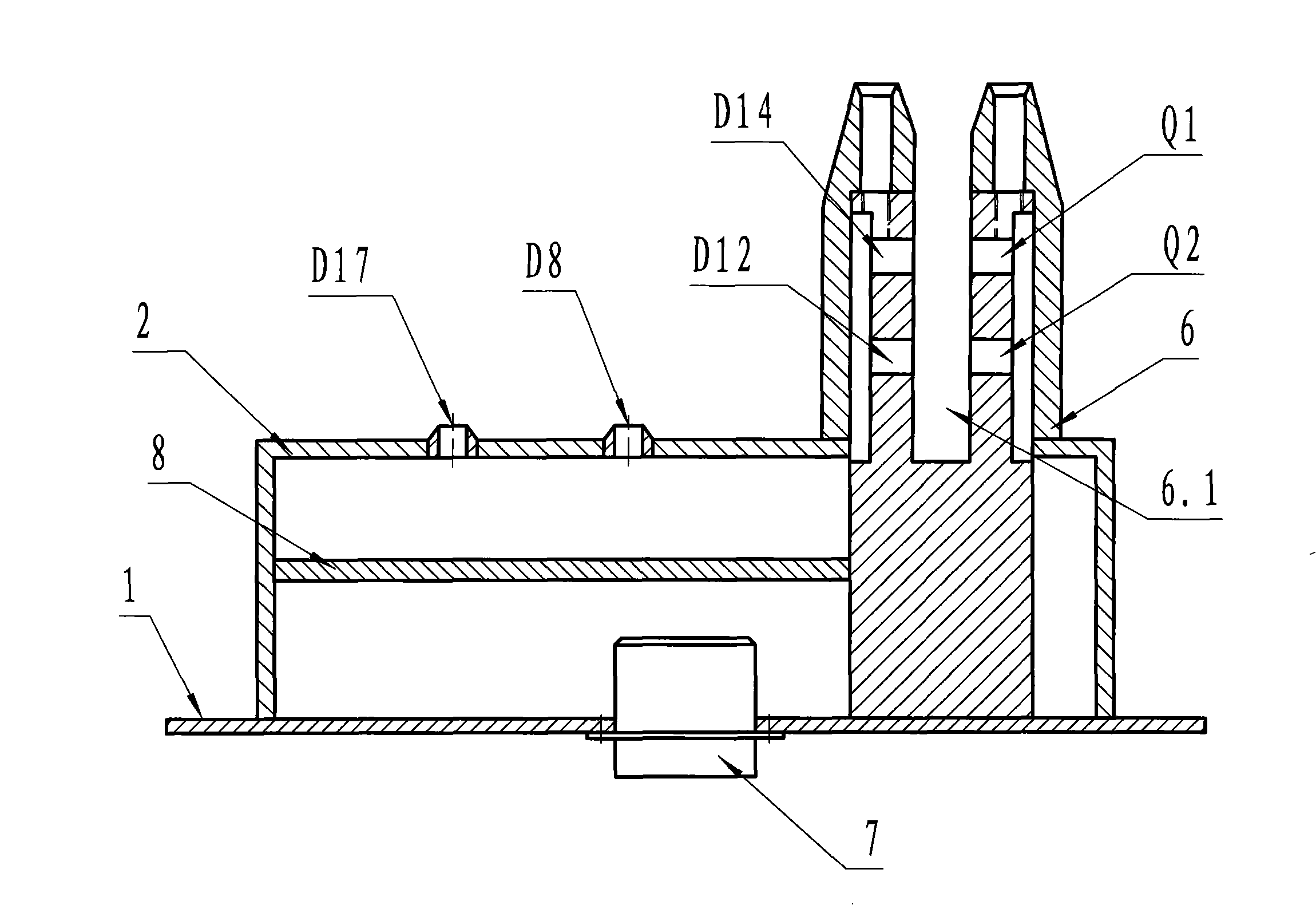

The invention belongs to the technical field of packing and relates to a coil paper detector used for a paper supply system of packaging equipment on a high speed production line of light industry. The detector consists of a base, a shell, a status display lamp, test light sources, a photoelectric induction device, a detecting head, an outgoing line plug-in and a detecting circuit board; wherein,the detecting head extends outside the shell, the front end of the detecting head is provided with a rectangular slot, and the two groups of test light sources and the photoelectric induction device are installed on the two walls of the slot in an opposite way; a detecting circuit comprises the test light sources, the photoelectric induction device, a signal amplification circuit, a data processing circuit, a signal output circuit and a status display circuit; when the tested wrapping paper normally passes through the rectangular slot of the detecting head, no control signal is output from the detector; when the tested wrapping paper has the phenomena of misplacement, discontinuity and failure crack, the control signal is output from the detector, and a controller and an actuator on the production line can be used for stopping the work of a host machine and the paper supply system, thus effectively ensuring the normal high speed running of the production line.

Description

Tray detector Technical field: The invention belongs to the technical field of packaging, and relates to a paper reel detector used in a paper supply system of a packaging equipment on a high-speed production line of light industry such as pharmaceuticals and food. Background technique: In the high-speed production lines of various industries in our country, the paper feeding speed of the paper feeding system of packaging equipment is generally 600 m / min. The paper feeding speed of some more advanced packaging equipment can reach 1600 m / min. The paper feeding system often occurs in production. If the paper is discontinuous, discontinuous, misplaced, or broken, if it cannot be found immediately and the machine is stopped, a packaging accident will occur, resulting in product loss. Summary of the invention: The purpose of the present invention is to provide a paper reel detector with simple structure and convenient installation and maintenance, which can effectively detect the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65B57/02B65B57/04B65B57/08G01N21/89G05B19/02

Inventor 李勇王万年

Owner 安徽科达自动化集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com