Low-density steel original austenite grain boundary display method and application

A technology of austenitic grain boundaries and low-density steel, which is applied in the preparation of test samples, etc., can solve problems such as unsatisfactory display effects, achieve improved display effects, low requirements for corrosion reagents and corrosion parameters, and are very easy to implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

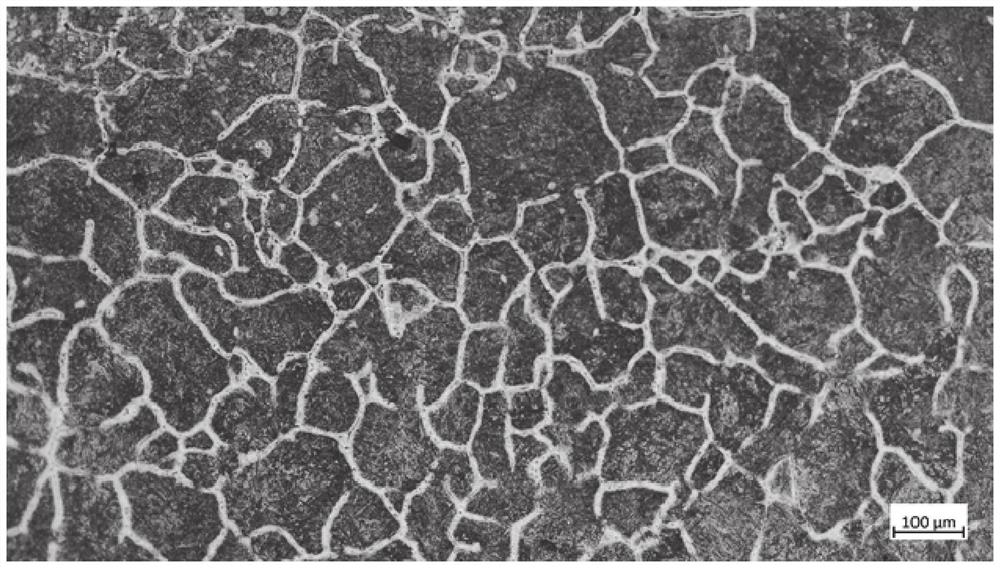

Embodiment 1

[0031] The method for displaying prior austenite grain boundaries in low-density steel, the specific steps are as follows:

[0032] (1) Put tin in a crucible, heat and keep warm for an appropriate time to melt all the tin;

[0033] (2) Polish one of the planes of the steel sample to be polished on 240#, 600#, 1000# metallographic sandpaper from coarse to fine, and keep a certain angle with the pattern plane when polishing 240#; replace the sandpaper each time Before ensuring that there is no scratch on the surface of the sample perpendicular to the polishing direction, when changing the sandpaper, the sample is rotated at an angle of 90 degrees, after being polished by 1000# sandpaper, water grinding is carried out on 1500# sandpaper, and after polishing by 1500# sandpaper, it is polished and polished. Blow dry until there are no scratches or stains;

[0034] (3) Quickly immerse the polished sample in step (2) in molten tin and keep it warm at 1050°C for 2 hours, then take ou...

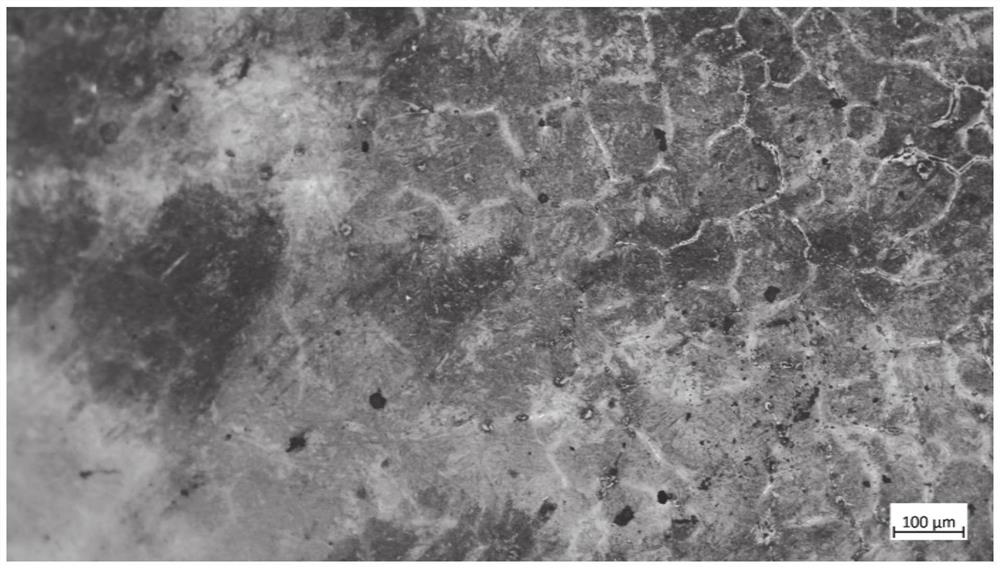

Embodiment 2

[0038] The method for displaying prior austenite grain boundaries in low-density steel, the specific steps are as follows:

[0039] (1) Put tin in a crucible, heat and keep warm for an appropriate time to melt all the tin;

[0040] (2) Polish one of the planes of the steel sample to be polished on 240#, 600#, 1000# metallographic sandpaper from coarse to fine, and keep a certain angle with the pattern plane when polishing 240#; replace the sandpaper each time Before ensuring that there is no scratch on the surface of the sample perpendicular to the polishing direction, when changing the sandpaper, the sample is rotated at an angle of 90 degrees, after being polished by 1000# sandpaper, water grinding is carried out on 1500# sandpaper, and after polishing by 1500# sandpaper, it is polished and polished. Blow dry until there are no scratches or stains;

[0041] (3) Quickly immerse the polished sample in step (2) into molten tin and keep it warm at 1050°C for 2.5 hours, then tak...

Embodiment 3

[0045] The method for displaying prior austenite grain boundaries in low-density steel, the specific steps are as follows:

[0046] (1) Put tin in a crucible, heat and keep warm for an appropriate time to melt all the tin;

[0047] (2) Polish one of the planes of the steel sample to be polished on 240#, 600#, 1000# metallographic sandpaper from coarse to fine, and keep a certain angle with the pattern plane when polishing with 300#; replace the sandpaper each time Before ensuring that there is no scratch on the surface of the sample perpendicular to the polishing direction, when changing the sandpaper, the sample is rotated at an angle of 90 degrees, after being polished by 1000# sandpaper, water grinding is carried out on 1500# sandpaper, and after polishing by 1500# sandpaper, it is polished and polished. Blow dry until there are no scratches or stains;

[0048] (3) Quickly immerse the polished sample in step (2) in molten tin and keep it warm at 1100°C for 2 hours, then ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com