Bending test device and using method

A bending test and platform placement technology, which is applied in the direction of measuring devices, using stable bending force to test the strength of materials, instruments, etc., can solve the problems of complex structure, poor operation stability and reliability, and limited application range, etc., to achieve the structure of the device Simple, stable and reliable operation, convenient mobile positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

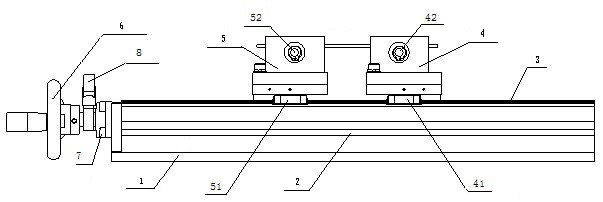

[0030] In order to overcome the problems of complex structure of the existing bending testing machine, cumbersome bending test operation for different workpieces, and poor adaptability, the present invention provides such figure 1 The bending test device shown in the present invention can adapt to the bending test operation of different workpieces by adjusting the distance between two movable workpiece placement platforms. The device has a simple structure and stable and reliable operation.

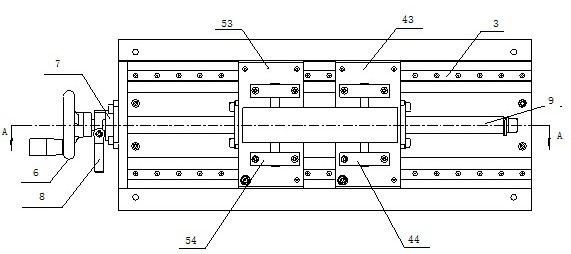

[0031] Such as figure 1 , figure 2 , image 3 As shown, a bending test device includes a base 1, a frame 2, a linear guide rail 3, a first workpiece placement platform 4, a second workpiece placement platform 5, and a platform position adjustment mechanism, wherein:

[0032] The platform position adjustment mechanism includes a hand wheel 6, a bearing 7, a bearing seat 10, a fixing clip 8 and a ball screw 9, and the bearing seat 10 is fixedly installed on the side of the frame 2, and t...

Embodiment 2

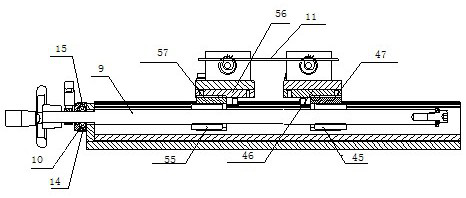

[0036] Preferably, on the basis of Embodiment 1, in this embodiment, preferably, the first workpiece placement platform 4 includes a first slider 41, a first support shaft 42, a first adapter plate 43, a first belt Seat bearing 44, first nut 45, first sliding seat 46 and right nut seat 47; described first sliding block 41 is connected with described linear guide rail 3, and described first sliding seat 46 is fixedly installed on described first sliding block On the block 41, the right nut seat 47 is fixedly installed on the bottom surface of the first slide seat 46, one end of the first nut 45 is installed on the right nut seat 47, and the other end is installed on the ball screw 9 , the first adapter plate 43 is fixedly installed on the first sliding seat 46, the first belt seat bearing 44 is respectively fixedly installed on both ends of the first adapter plate 43, and the first support shaft 42 is mounted on the first belt unit bearing 44 .

[0037] The second workpiece pl...

Embodiment 3

[0048] On the basis of embodiment 2, a kind of using method of bending test device, concrete steps are as follows:

[0049] S1: Installation of the workpiece to be tested;

[0050] Place the workpiece 11 to be measured on the first support shaft 42 of the first workpiece placement platform 4 and the second support shaft 52 of the second workpiece placement platform 5;

[0051] S2: adjust the platform position;

[0052] By turning the hand wheel 6, the ball screw 9 is driven to rotate, and the ball screw 9 drives the first nut 45 and the second nut 55 to move in reverse synchronously, thereby driving the first sliding seat 46 to move rightward along the linear guide rail 3, and at the same time Drive the second sliding seat 56 to move synchronously to the left along the linear guide rail 3, thereby realizing the distance adjustment between the first supporting shaft 42 installed on the first sliding seat 46 and the second supporting shaft 52 installed on the second sliding sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com