60AT turnout switch rail transverse wave ultrasonic detection reference block and detection method

A technology of ultrasonic testing and comparison of test blocks, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. It can solve problems such as undetectable defects and reduce railway operation. risk, improve the level of defect detection rate, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

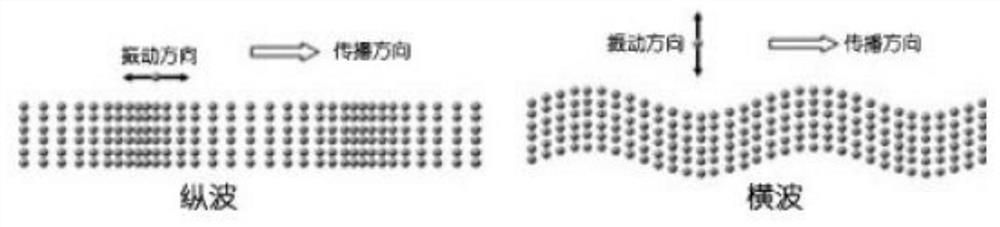

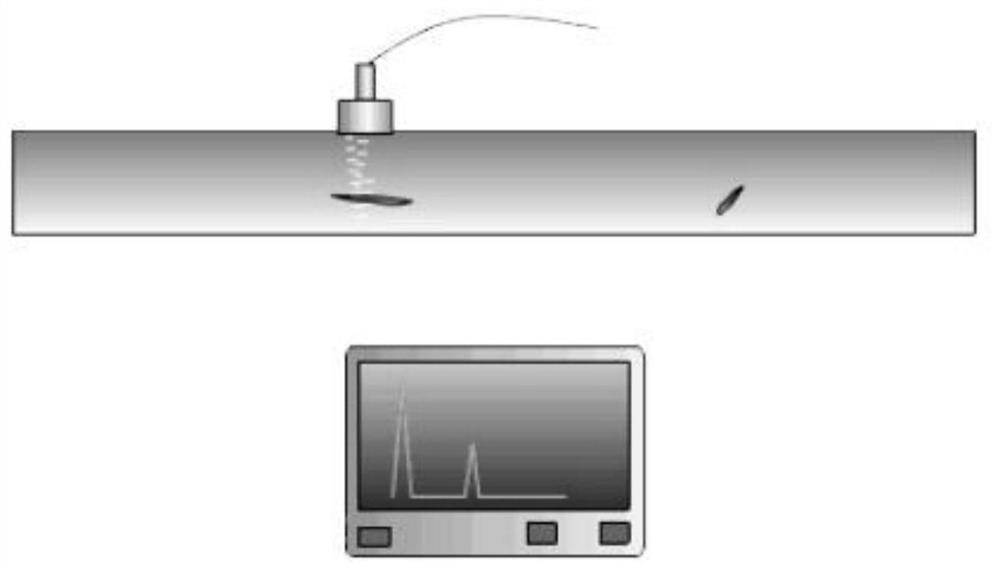

[0038] Ultrasonic testing usually requires a sensitivity calibration of a comparison test block, because the traditional ultrasonic testing of switch point rails uses longitudinal wave ultrasonic testing, so there is no comparison test block for switch point rail shear wave ultrasonic testing. For this reason, it is necessary to design a comparative test block for the shear wave ultrasonic testing of switch point rails. Different types of rails may correspond to comparison test blocks with different parameters. In this embodiment, 60AT rails are taken as an example for illustration.

[0039] The invention discloses a comparative test block for transverse wave ultrasonic detection of 60AT switch point rails, which is the same specification, model and material as the 60AT switch point rails, and is drilled perpendicular to the cross-section at the 20mm distance from the rail head of the 60AT rail to the top of the non-working side rail. A flat-bottomed hole with a diameter of Φ2...

Embodiment 2

[0041]The invention also discloses a 60AT turnout tip rail transverse wave ultrasonic detection including rail head detection, rail waist detection and rail bottom detection, wherein the rail head detection includes the rail head rail surface detection and the rail head side detection, and the rail bottom detection includes the inside and outside of the rail bottom Upper surface inspection, rail bottom middle inspection, rail bottom inner and outer side inspection. The specific operation of each ultrasonic test is described below.

[0042] 1. Ultrasonic testing of rail head

[0043] 1. Ultrasonic testing of rail head and rail surface

[0044] First, place the probe with a refraction angle of 70° on the rail head rail surface of the comparison test block, move the probe to find the maximum reflected echo of the first flat-bottomed hole, adjust the gain or attenuator so that the reflected wave reaches 80% of the full screen, and then Improve the detection sensitivity by 6dB wh...

Embodiment 3

[0064] The invention also discloses a method for determining each parameter of the comparison test block for the transverse wave ultrasonic detection of the turnout tip rail through the orthogonal test method, which saves 2 / 3 of the workload compared with the comprehensive test.

[0065] Also take the 60AT rail as an example to demonstrate, first select the optional items of the parameters of the first flat-bottomed hole according to the professional knowledge (for the convenience of expression, only 3 groups are needed), that is, the level of each factor, and record the optional parameters of the first flat-bottomed hole in the table 1.

[0066]

[0067] Table 1

[0068] The above test is a three-factor and three-level test. If a comprehensive test is carried out, 3 3 =27 trials, while using the orthogonal experiment L9, only 9 trials are required. Compared with full-scale testing, the workload is reduced by 2 / 3.

[0069] The longer the time is, the greater the error in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com