Semiconductor device heat dissipation structure

A heat dissipation structure and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as the influence of IGBT module terminals, and achieve a high-safety and practical solution that eliminates adverse effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

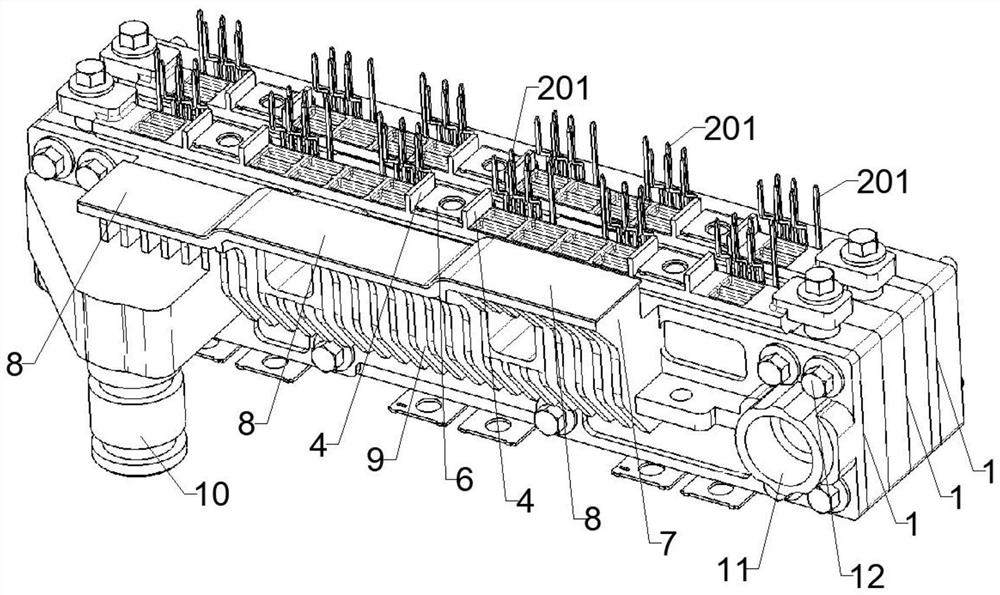

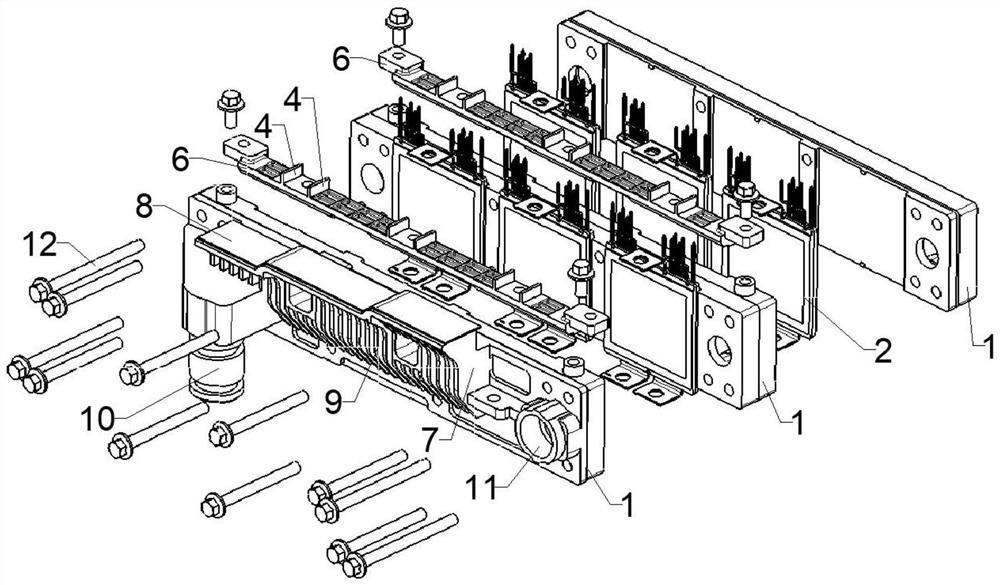

[0040] This embodiment provides a heat dissipation structure for a semiconductor device, which is used to solve the technical problem that when the bolts connecting the busbars to the IGBT module are unscrewed, it is easy to cause adverse effects on the terminals of the IGBT module.

[0041] The heat dissipation structure of the semiconductor device includes a main body, which is provided with an interlayer 3 and a cavity, the interlayer 3 is used to wrap the IGBT module 2, and the terminal 201 of the installed IGBT module 2 protrudes from the top of the main body, and the cavity is used In this way, when the interlayer 3 is wrapped with the IGBT module 2 and the cavity is filled with cooling liquid, by means of the heat conduction of the wall between the interlayer 3 and the cavity, the IGBT module can 2 The heat generated by the operation is transferred to the cooling liquid, thereby dissipating heat from the IGBT module 2, and also transferring the cold energy of the cooling...

Embodiment 2

[0046]This embodiment is further improved on the basis of Embodiment 1. In the semiconductor device heat dissipation structure provided by this embodiment, a boss 7 is provided on the side wall of the main body. The top of the boss 7 is a plane, and the busbar 5 is connected to On the upper surface of the boss 7, in this way, the boss 7 can support the busbar 5, and, because the boss 7 is connected to the side wall of the main body, the heat generated by the busbar 5 is conducted through the boss 7 and the main body. And the cooling liquid that reaches the above-mentioned cavity performs heat exchange, and the cooling liquid can also perform heat dissipation and cooling on the busbar 5 to cool the busbar 5, effectively solving the problem of heat dissipation of the busbar 5, thereby preventing the temperature of the busbar 5 from being too high As a result, the temperature rise in the internal space of the controller is too large to affect the IGBT module 2. Therefore, the heat...

Embodiment 3

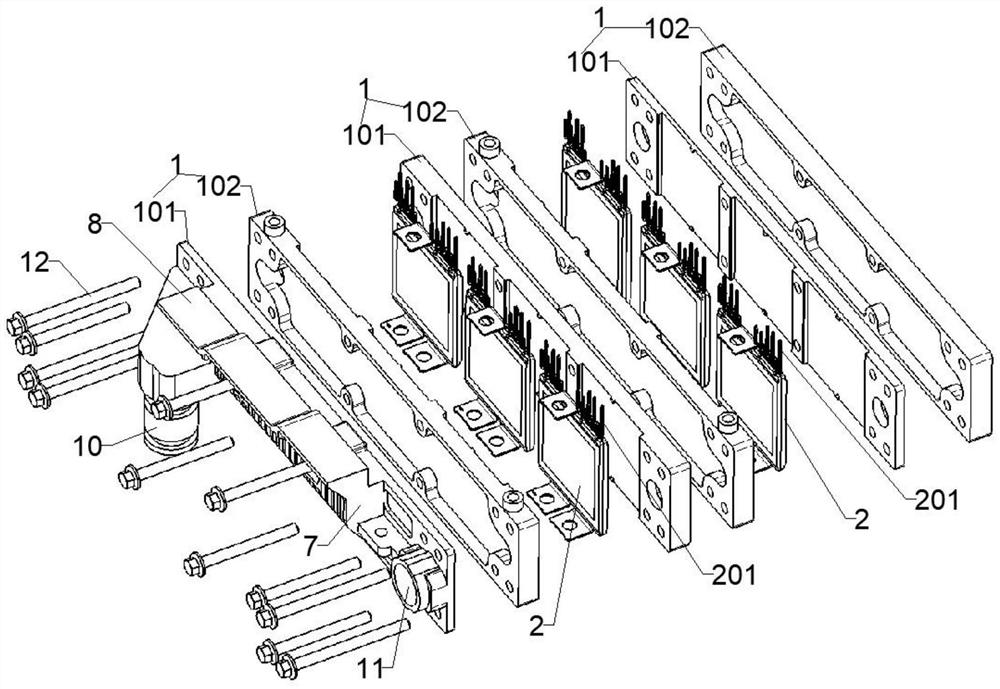

[0050] This embodiment serves as an implementation of the above-mentioned embodiment. In the semiconductor device heat dissipation structure provided by this embodiment, the above-mentioned main body includes several composite boards 1, and several composite boards 1 are overlapped and connected together. A layer of the above-mentioned interlayer 3 is formed between the boards 1. It should be noted that the number of IGBT modules 2 that can be wrapped in each interlayer 3 can be changed by setting the length of the composite board 1. Optimally, in each interlayer 3 is provided with three clamping positions, and each clamping position can clamp one IGBT module 2, that is, three IGBT modules 2 can be clamped in each interlayer 3, and the three clamping positions are distributed at equal intervals.

[0051] A chamber 103 is provided inside each composite board 1 , and when all the composite boards 1 are overlapped and connected together, all the chambers 103 communicate to form th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com