Multistage filtering device for tartaric acid processing

A technology of stage filtration and tartaric acid, which is applied in the direction of filtration circuit, filtration separation, fixed filter element filter, etc., can solve problems such as device blockage, poor fluidity of tartaric acid, and influence of tartaric acid filtration, so as to improve fluidity, improve filtration efficiency, slow down The effect of flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

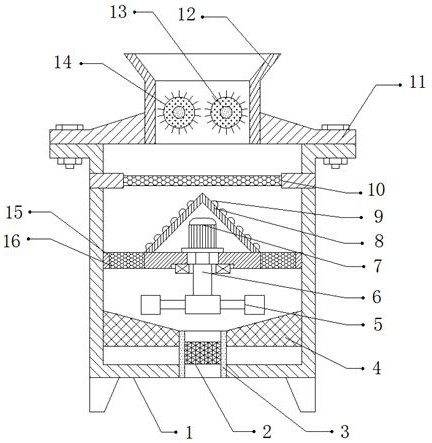

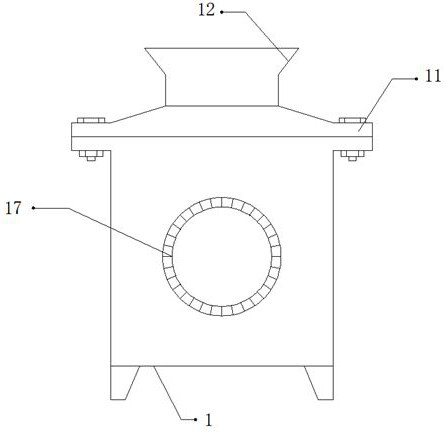

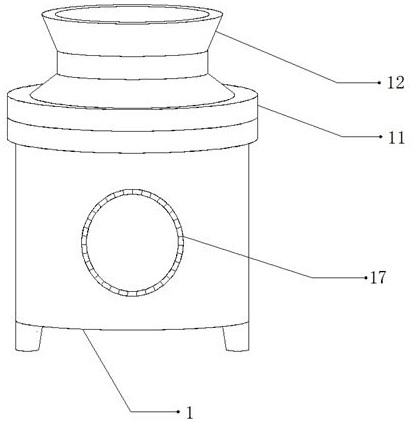

[0030] refer to Figure 1-4 , a kind of tartaric acid processing multi-stage filtering device, comprises filter tank 1, and the inner wall of filter tank 1 is connected with fixed plate 15 by bolt, and the top outer wall of fixed plate 15 offers the filter hole 16 that equidistant is annular distribution, fixed plate The bottom outer wall of 15 is connected with rotating shaft 6 by bearing rotation, and the bottom outer wall of rotating shaft 6 is connected with stirring mechanism 5 by bolt, and stirring mechanism 5 mainly is made up of rotating disk 19 and plectrum 18, and rotating disk 19 and plectrum 18 are connected by bolts, the top outer wall of the fixed plate 15 is connected with the motor 7 by bolts, and one end of the output shaft of the motor 7 is connected with the rotating shaft 6 by bolts, the top outer wall of the filter tank 1 is connected with the tank cover 11 by bolts, And the top outer wall of the tank cover 11 is provided with a feed hopper 12 .

[0031] ...

Embodiment 2

[0034] refer to Figure 5 , a kind of tartaric acid processing multi-stage filtering device, present embodiment is compared with embodiment 1, the inner wall of feeding hopper 12 can also be connected with deflector 21 by bolt, and the outer wall of deflector 21 is provided with equidistant distribution The soft spines 20.

[0035] Working principle: when in use, the tartaric acid that needs to be filtered is filled into the filter tank 1 through the feed hopper 12, and the falling speed of the tartaric acid is slowed down by the deflector 21, so that the filter sieve 10 can initially filter the tartaric acid. The soft thorns 20 can clean up the impurities mixed in the tartaric acid, and the tartaric acid after preliminary filtration falls on the fixed plate 15 through the guidance of the V-shaped cover 8, so that the tartaric acid is further filtered through the filter hole 16, and the switch is turned on. The motor 7 will drive the rotating shaft 6 to rotate, thereby stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com