Device for processing kitchen garbage into fertilizer

A kitchen waste and fertilizer technology, applied in organic fertilizer, grain treatment, climate change adaptation, etc., can solve the problems of reducing the service life of the device, idling of the stirring device, and reducing the efficiency of stirring, so as to improve the buffering capacity and enhance the buffering effect , Guarantee the effect of crushing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

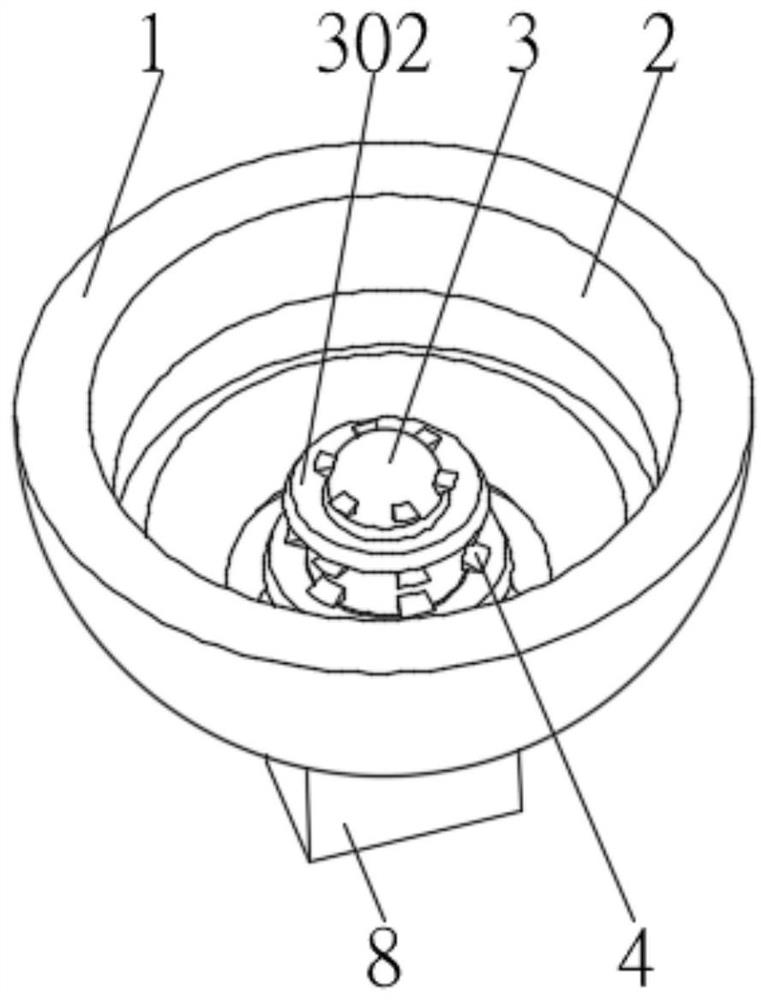

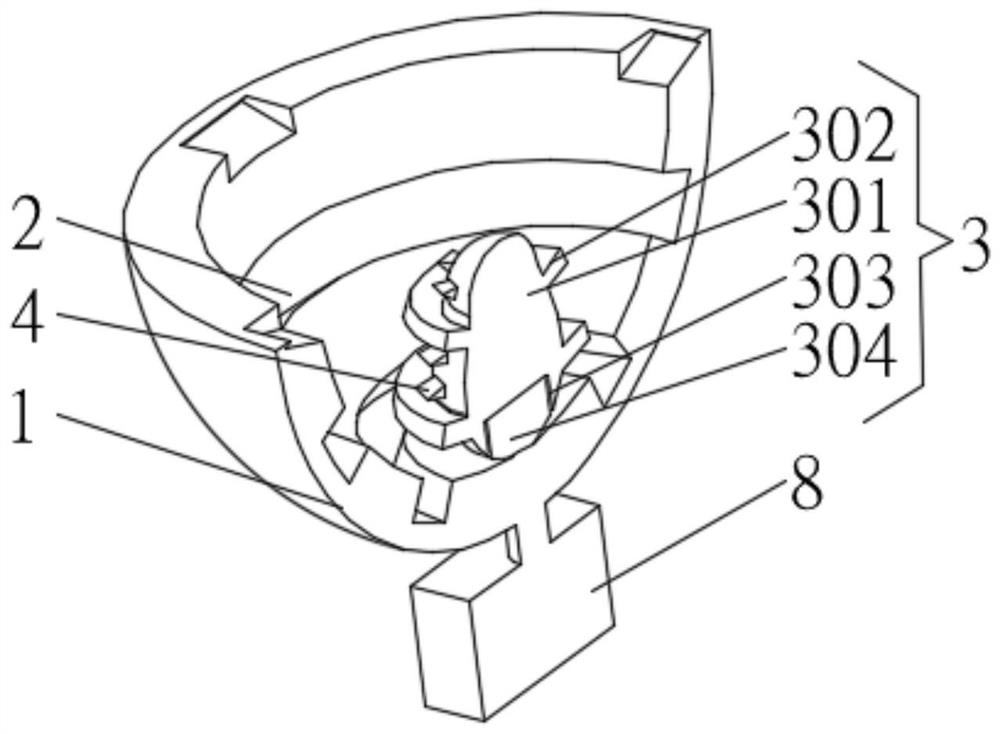

[0031] see Figure 1-4 , the present invention provides a technical solution: a kitchen waste processing fertilizer device, including a processing barrel 1, the processing barrel 1 is a hemispherical barrel, the inner wall of the processing barrel 1 is uniformly provided with a track groove 2, and the inner bottom of the processing barrel 1 is installed with Processing ball 3, rolling device 4 is installed on the outside of processing ball 3, kitchen waste processing fertilizer device, including processing bucket 1, characterized in that: processing bucket 1 is a hemispherical bucket, and the inner wall of processing bucket 1 is uniformly provided with track grooves 2 , processing ball 3 is installed on the inside bottom of processing barrel 1, and rolling device 4 is installed on the outside of processing ball 3,

[0032] The processing ball 3 includes a rolling ball 301. The outer side of the rolling ball 301 is symmetrically equipped with a track ring 302. The track ring 30...

Embodiment 2

[0037] see Figure 1-4 , the present invention provides a technical solution: on the basis of Embodiment 1, a cooling device 5 is installed on the top of the processing ball 3, the cooling device 5 is connected to the rolling device 4, the cooling device 5 includes a cooling tank 501, and the cooling tank 501 is set On the top of the processing ball 3, the bottom of the cooling tank 501 communicates with the rolling tank 401, the inner bottom of the cooling tank 501 is equipped with a heat conduction rod 502, and the end of the heat conduction rod 502 extending to the outside of the cooling tank 501 is evenly equipped with a cooling fin 503.

[0038] Both sides of the reciprocating rod 403 are provided with pushing grooves 9, and the outside of the heat conducting rod 502 is uniformly equipped with gear bumps 10, which extend to the inside of the pushing groove 9, and the heat conducting rod 502 is rotationally connected with the cooling groove 501.

[0039] When in use, the h...

Embodiment 3

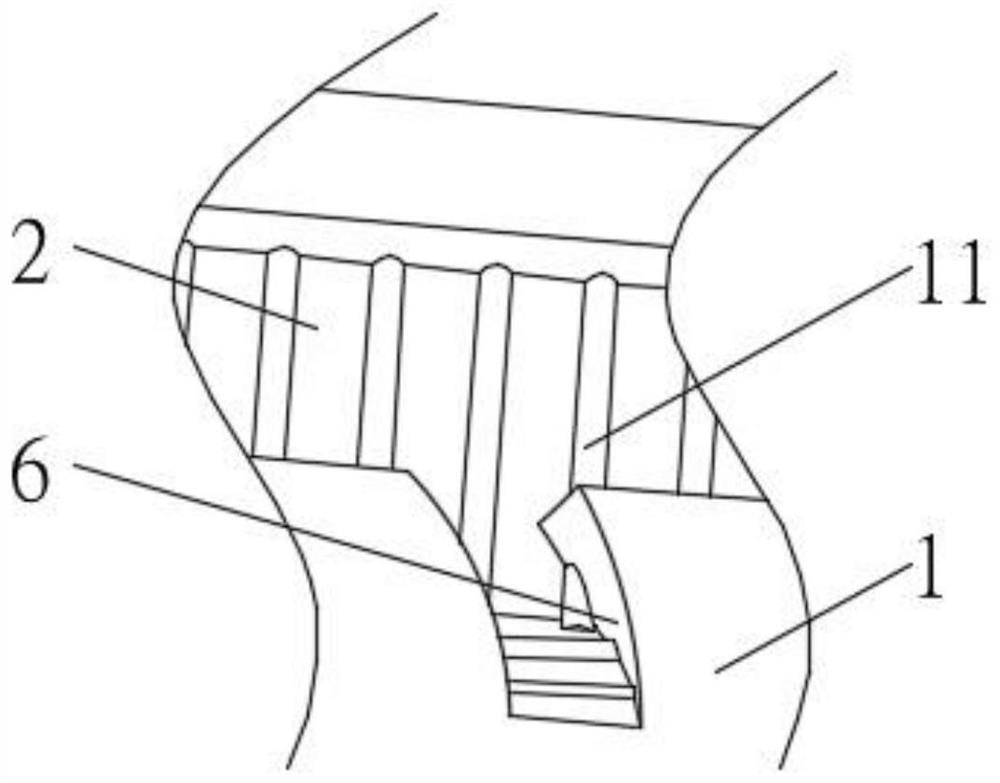

[0042] see Figure 1-4 , the present invention provides a technical solution: on the basis of Embodiment 1, a semicircular rod 11 is fixedly connected to one side of the inner wall of the track groove 2 and the guide groove 6, and the track ring 302 is slidably connected to the semicircular rod 11.

[0043] When in use, the processing ball 3 is lifted toward the center of the processing barrel 1 by the semicircular rod 11 when sliding along the guide groove 6 and the track groove 2, and then clings to the inner wall of the processing barrel 1 again due to centrifugal action, and the processing ball 3 moves along the track During the sliding process, the groove 2 is continuously lifted by the semicircular plate 11 and then hits the inner wall of the processing barrel 1, which can realize continuous impact crushing of the kitchen waste and ensure the degree of crushing of the kitchen waste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com