Wood processing equipment

A technology for processing equipment and wood, used in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of low processing speed, unsuitable machines, inconsistent product quality, etc., to improve work efficiency and quality. Stable and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

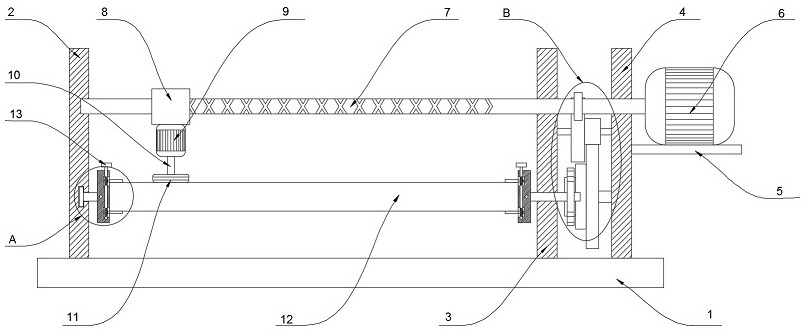

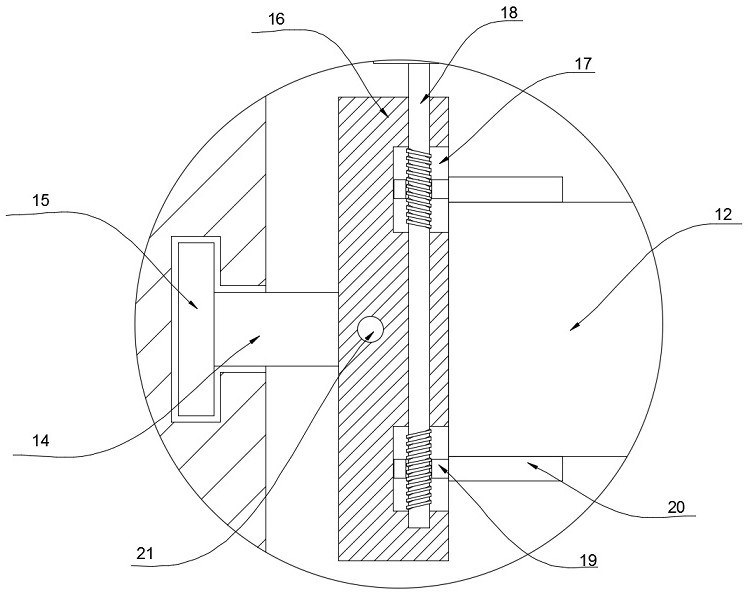

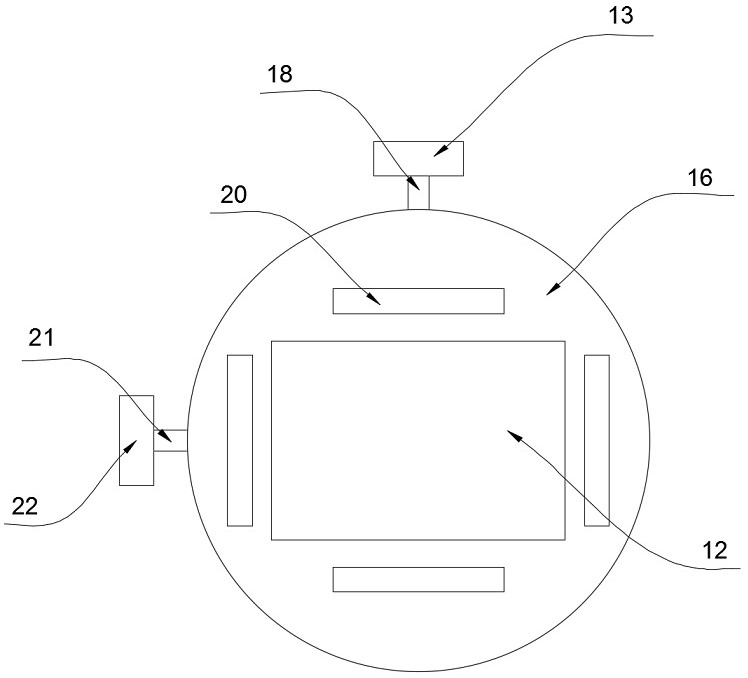

[0023] refer to Figure 1-5 , a kind of wood processing equipment, comprising a load-bearing base 1, a support column 2 is welded and fixed above the load-bearing base 1, the support column 2 is perpendicular to the load-bearing base 1, a first baffle plate 3 is welded and fixed on the top of the load-bearing base 1, and the top of the load-bearing base 1 is welded The second baffle 4 is fixed, the first baffle 3 and the second baffle 4 are parallel to each other, the first baffle 3 is rotatably connected to the second axle 32, and the outer side of the second baffle 5 is welded and fixed with a fixed frame 5, The top of the fixed frame 5 is fixed with a servo motor 6 by bolts, the output end of the servo motor 6 is coaxially welded and fixed with a reciprocating screw 7, the reciprocating screw 7 is engaged with a movable block 8, and the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com