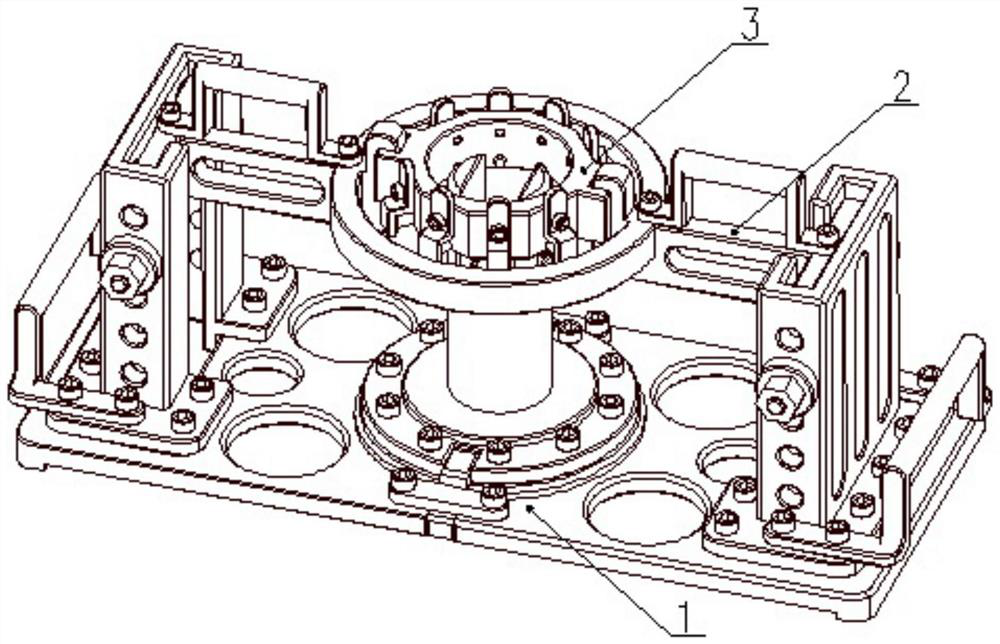

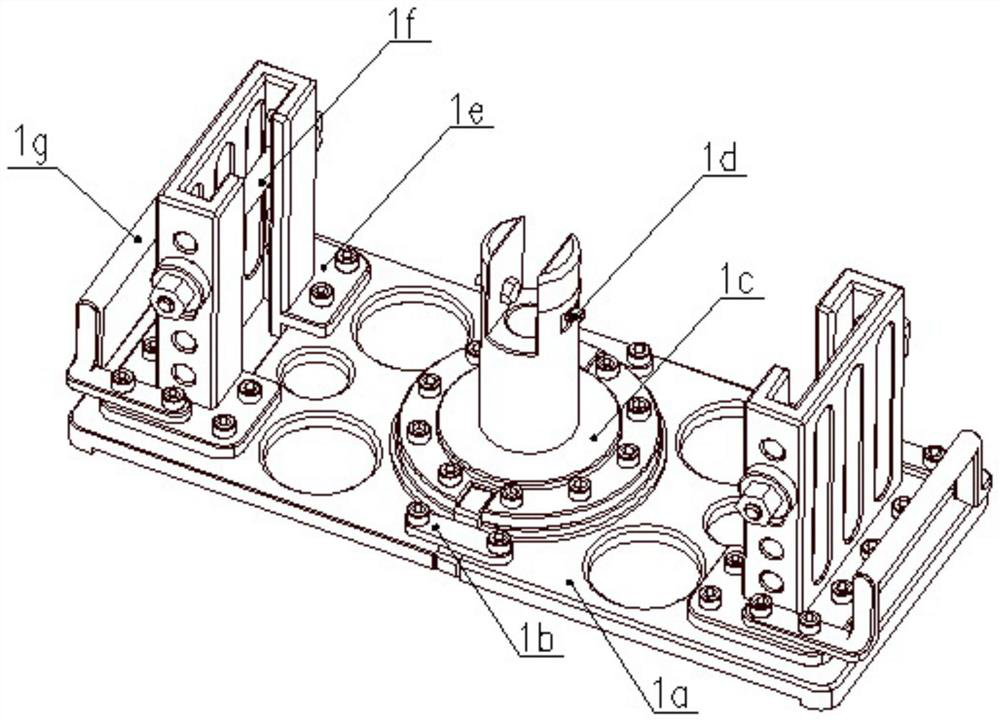

High-pressure turbine rotor assembly air guide runway installing and positioning device and method

A high-pressure turbine, installation and positioning technology, applied to workpiece clamping devices, manufacturing tools, wind power generation, etc., can solve the problems of poor installation and positioning accuracy and low efficiency, and achieve the effect of improving assembly quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below.

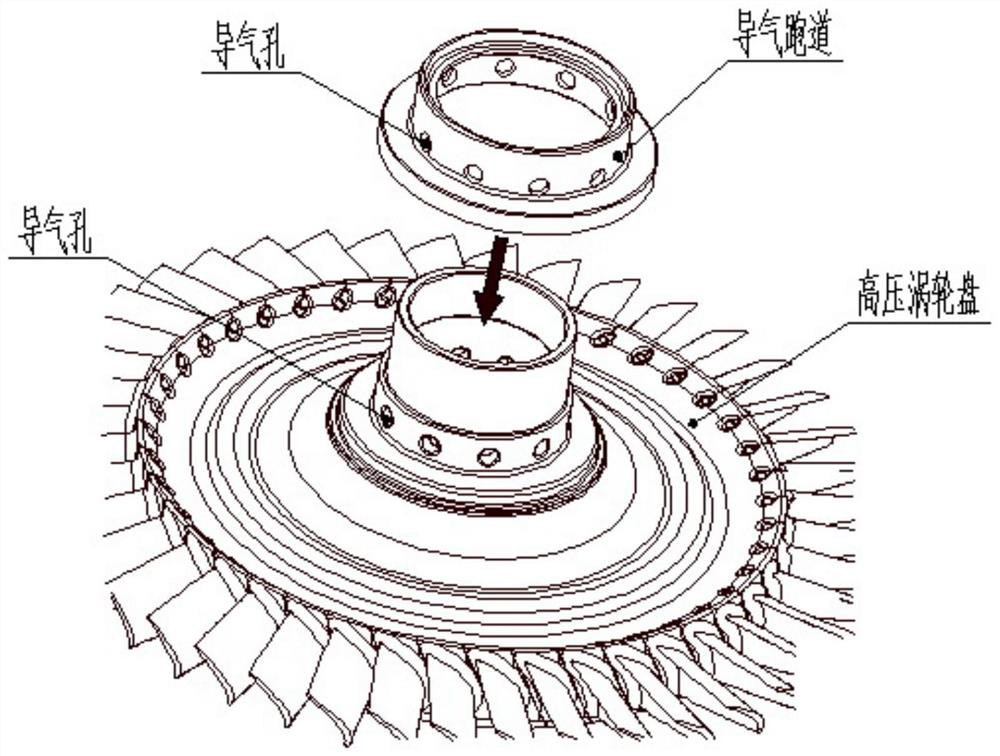

[0022] figure 2 It is a schematic diagram of the installation of the air guide runway on the high-pressure turbine disk; because the air guide runway and the high-pressure turbine disc are tightly fit, the air guide runway needs to be heated at high temperature during assembly, and then the air guide runway is heated and expanded to quickly It is pressed into the journal stop of the high-pressure turbine disc, but at the same time, since the air guide runway and the corresponding high-pressure turbine disc journal are provided with uniformly distributed air guide holes in the circumferential direction, the two air guide holes must be completely aligned to ensure The normal operation of the high-pressure turbine rotor assembly, and once the air guide hole is not completely aligned during the pressing process, only disassembly and reassembly of the temperature difference is required. Use any tool to adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com