An automated assembly tooling for antenna arrays

A technology of antenna array and assembly tooling, which is applied to antenna supports/installation devices, motor vehicles, lifting devices, etc., which can solve the problems of long preparation time for hoisting, waste of resources and costs, and inconvenient operation, and improve the convenience of operation , Ensure assembly efficiency and reduce the effect of hoisting and transshipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

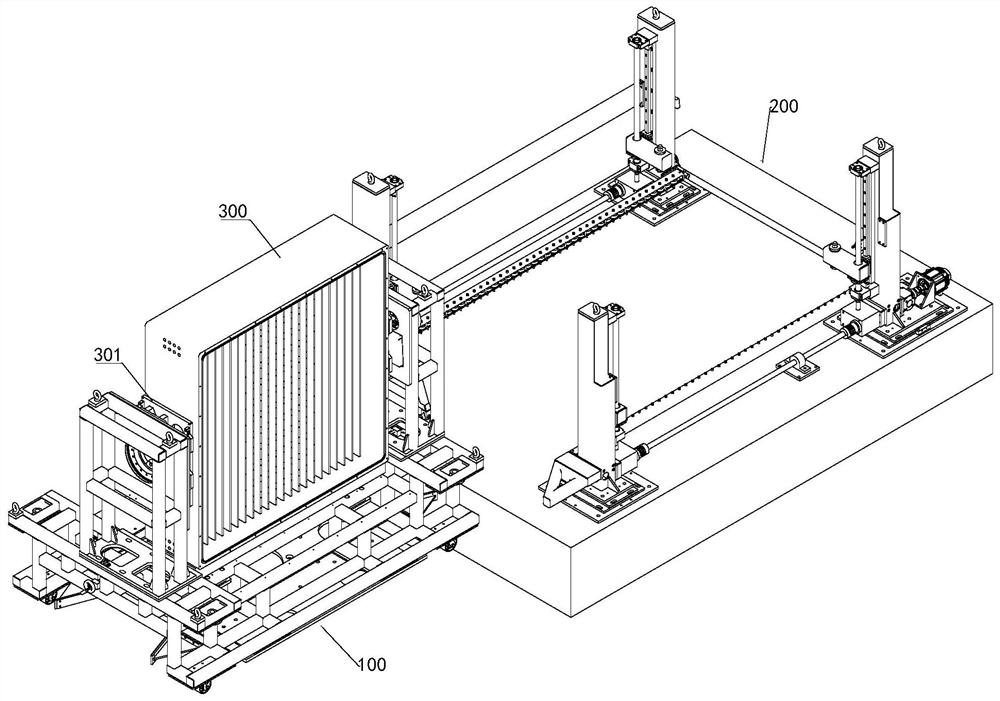

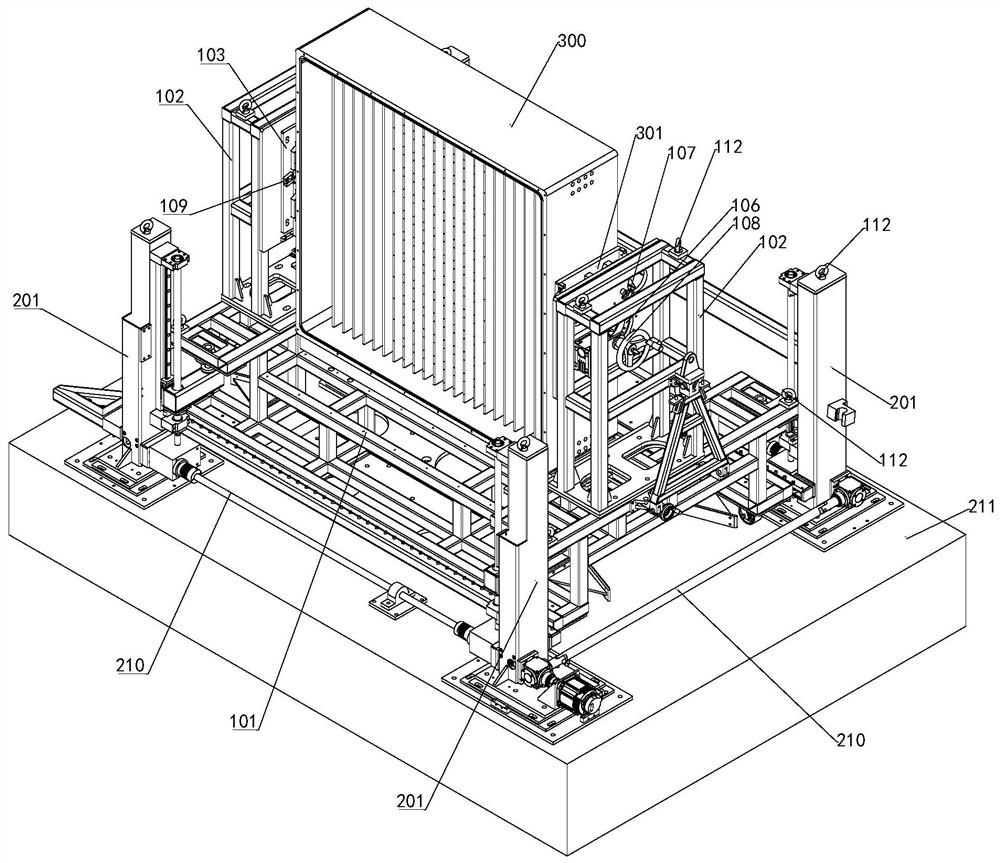

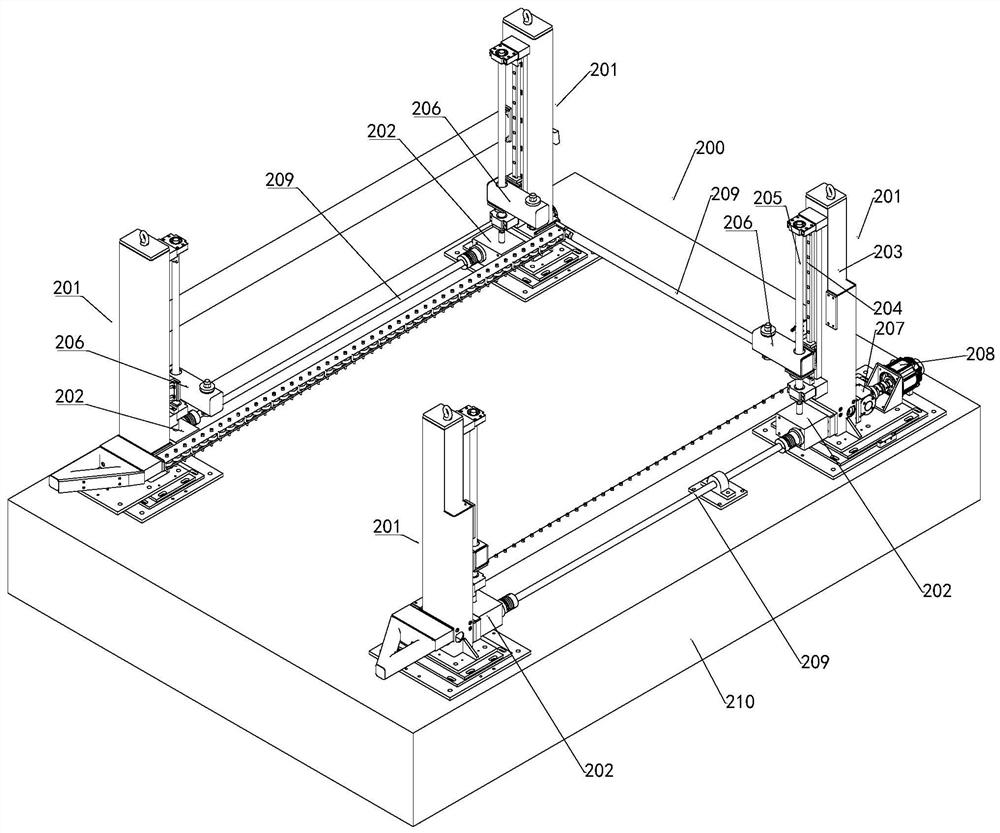

[0036] Such as Figure 1-Figure 4 As shown, an antenna array automatic assembly tool in this embodiment includes a movable transfer tool 100 and a lifting positioning tool 200. The transfer tool 100 includes a base 101 and a clamping part, and the clamping parts are two And symmetrically installed on the base 101, a space for assembling the antenna array 300 is reserved between the two clamping parts; the lifting and positioning tool 200 includes several independently arranged and mutually driven lifting parts 201, The transfer tool 100 can be moved between several lifting parts 201 and locked therewith.

[0037] Such as figure 1 , figure 2 and Figure 4 As shown, the clamping part of this embodiment includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com