Concrete cutting device for highway construction

A cutting device and concrete technology, which is applied in the direction of roads, roads, road repairs, etc., can solve problems such as poor control, tired operation of construction personnel, and broken cutting pieces, so as to facilitate movement, avoid arm fatigue, and avoid damage to cutting pieces Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

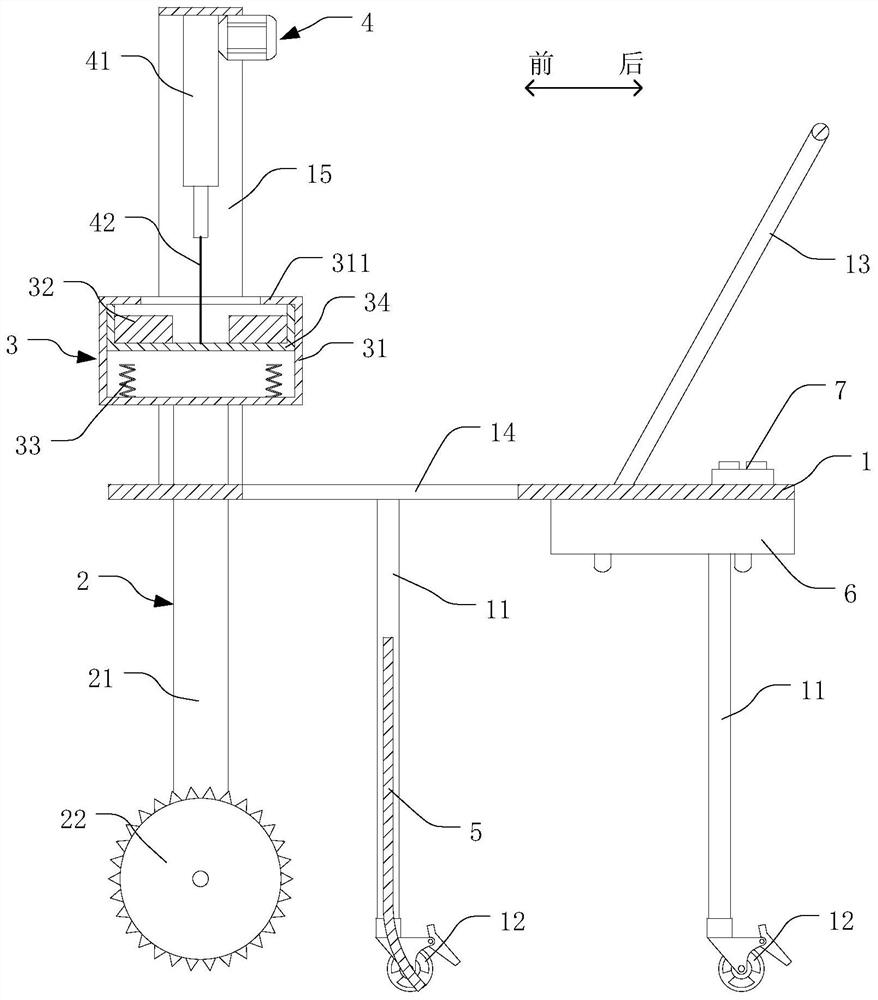

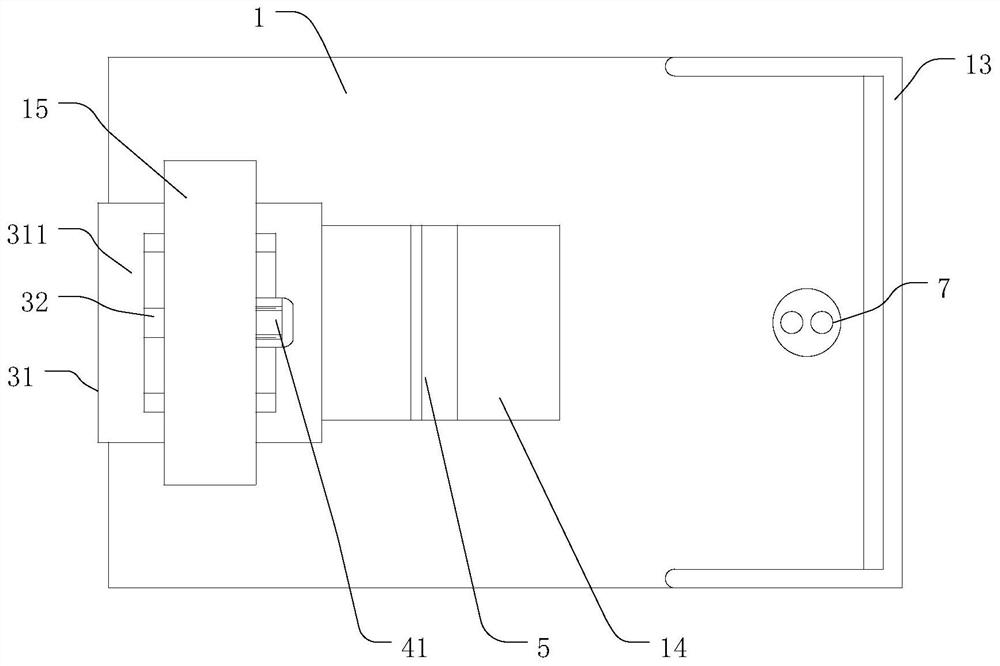

[0027] see Figure 1 to Figure 3 , The present invention provides a concrete cutting device for road construction, including a workbench 1, a cutting mechanism 2, a constant weight mechanism 3 and a lifting mechanism 4. The bottom of the workbench 1 is provided with a plurality of supporting legs 11 , and the bottom of each supporting leg 11 is provided with a roller 12 . The cutting mechanism 2 is slidably arranged on the front part of the workbench 1 up and down, and is used for cutting concrete. The constant weight mechanism 3 is fixedly connected to the upper end of the cutting mechanism 2 and is used to provide a constant downward pressure to the cutting mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com