A pressurized coring system and method

A coring and core technology, which is used in the extraction of undisturbed core devices, earthwork drilling, drilling equipment, etc. The phenomenon of core cake formation, the effect of speeding up the drilling rate and improving the recovery factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this application, when core sampling is carried out in the existing high in-situ stress environment, it is often impossible to obtain well-preserved core samples due to the stratum stress in which the rock mass is located. The initial in-situ stress is divided into for the following levels:

[0040] 1. Extremely high ground stress The maximum stress value of the vertical axis: ≥40MPa

[0041] Hard rock: During the excavation process, rockbursts sometimes occur, rock blocks pop up, the rock mass of the cave wall is peeled off, and there are many new cracks;

[0042] 2. High ground stress The maximum stress value of the vertical axis: 20-40MPa

[0043] Soft rock: The core of the drilled hole has a cake phenomenon, and the rock mass of the wall of the hole is peeled off during the excavation process, and the displacement is extremely significant, and even a large displacement occurs, which lasts for a long time and is not easy to form a hole; the rock mass of the found...

Embodiment 2

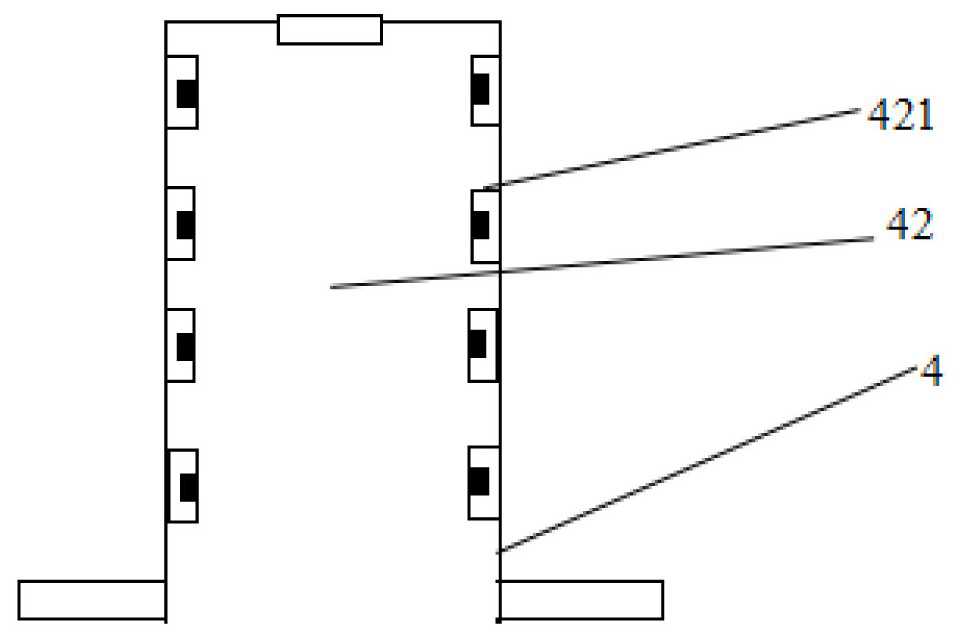

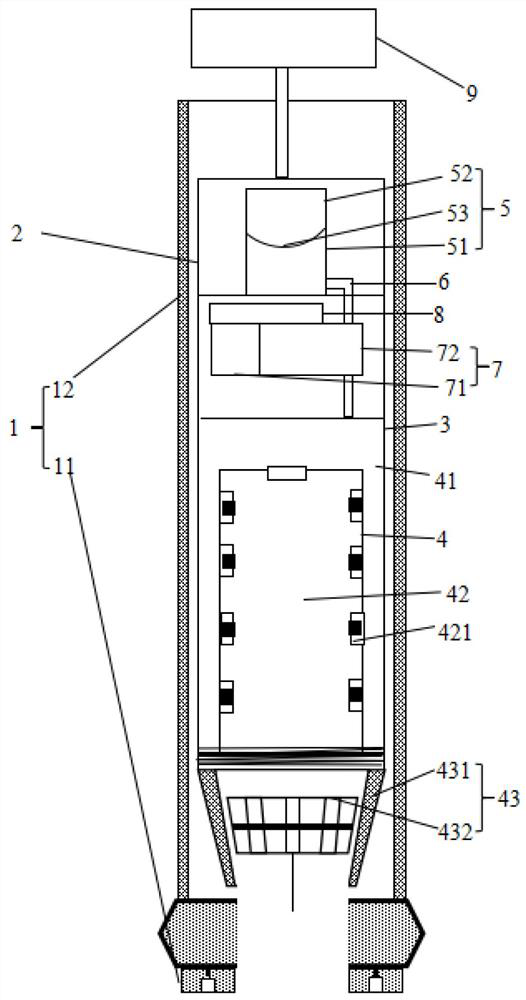

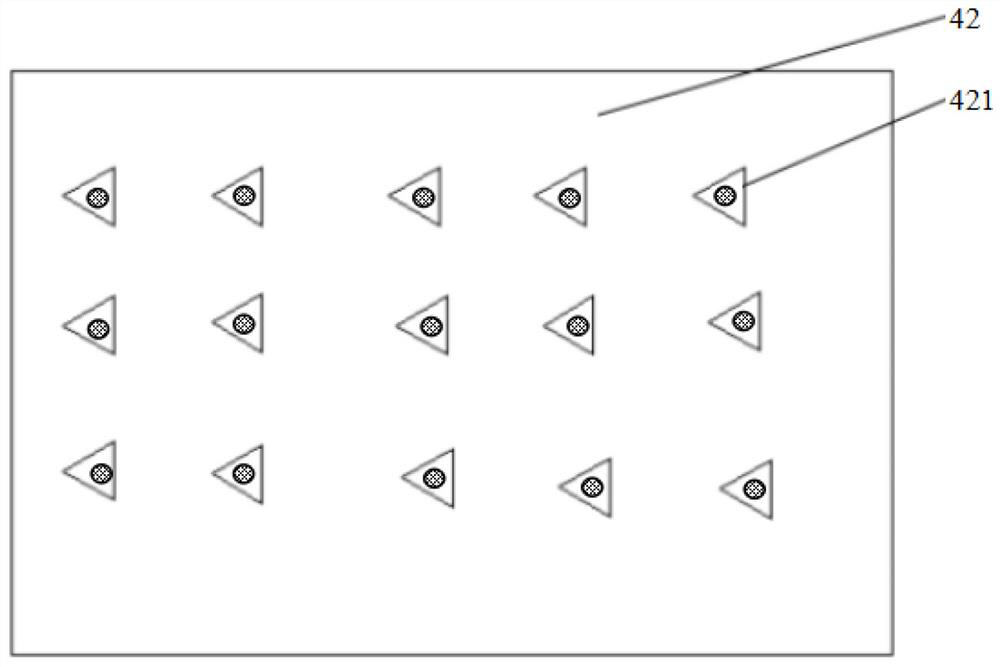

[0057] A pressurized coring system of the present application is especially suitable for performing stress-preserving coring work on rocks in a high ground stress environment. After the coring device collects the cores from the rock mass, the cores are inserted into the one-way sealed core chamber 42 made of high wear-resistant rubber sleeves, wherein the cores in the exposed part are processed by a certain pressure of the downhole mud. The stress is preserved, and the rock core wrapped by the rubber sleeve is transported a certain amount of high-pressure fluid into the high-pressure fluid chamber 41 through the micropump arranged on the core pipe 2 inside the drill pipe 12, so that the high-pressure fluid chamber 41 passes through the counter chamber. The expansion pressure of the wall is applied to the surface of the core wrapped by the rubber sleeve to apply the same pressure that the core was subjected to in the rock mass in the initial state, so as to realize the stress fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com