A high-efficiency drying equipment for cement production

A kind of drying equipment and high-efficiency technology, which is applied in the direction of drying, dryer, lighting and heating equipment, etc., can solve the problems of long cooling time, increased equipment cost, and burns of workers, so as to improve production efficiency and reduce cooling Occupancy time, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

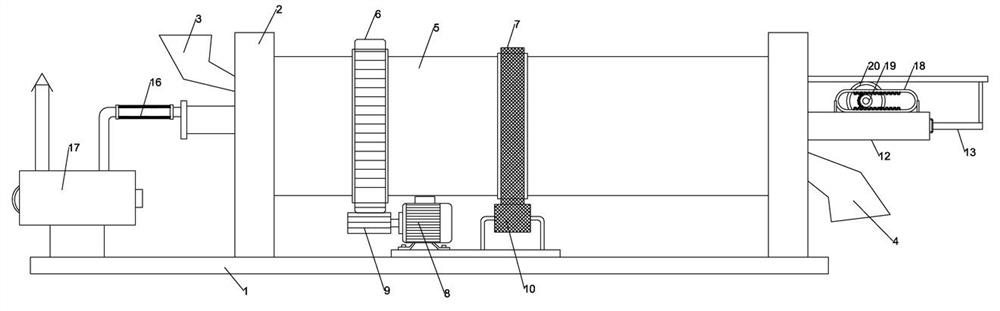

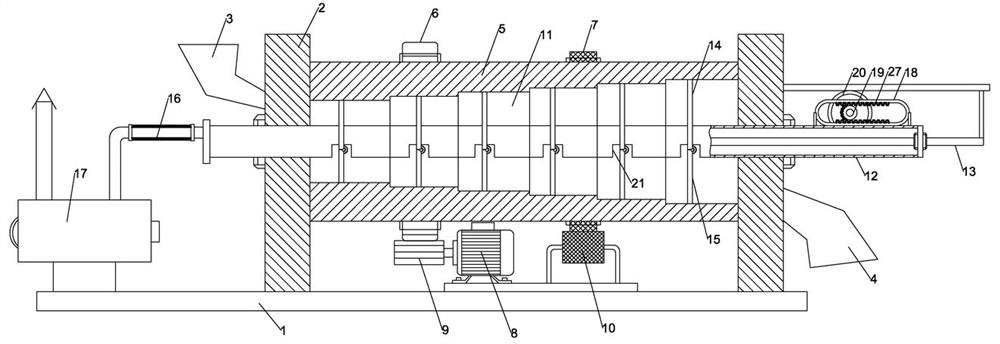

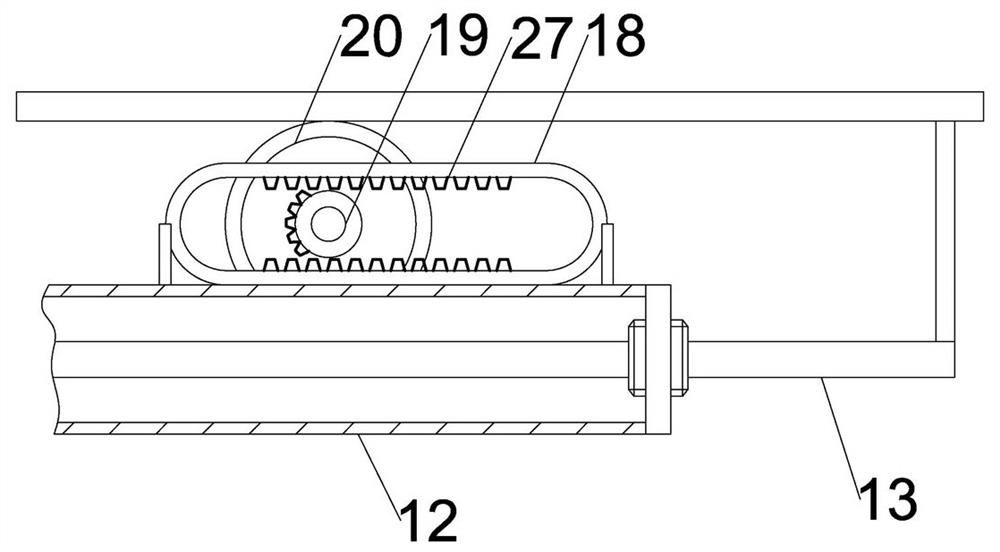

[0020] Depend on figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 Provided, a high-efficiency drying equipment for cement production, including a base plate 1 and two end covers 2 fixed on the base plate 1, a cylinder 5 with open ends at both ends is rotatably installed between the two end covers 2, A hot blast stove 17 is fixed on the bottom plate 1, and it is characterized in that the two end covers 2 are respectively provided with a feed port 3 and a discharge port 4 communicating with the drum 5, and the drum 5 is covered with an inherent coaxial line The ring gear 6 is provided, the first motor 8 is fixed on the base plate 1, the gear 9 is fixed on the output end of the first motor 8 and the gear 9 and the ring gear 6 are engaged with each other, and the inside of the drum 5 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com