Porous niobium carbide MXene/reduced graphene oxide-based heating film

An alkene-based heating film and graphene-based technology, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve problems such as brittleness, poor flexibility of graphene heating coatings, and limited infrared emissivity, and achieve The effect of good flexibility and stretch resistance, excellent thermal conductivity, and excellent electronic conductivity

Inactive Publication Date: 2021-02-05

FOSHAN SHUNDE SANBEI ELECTRONICS CO LTD

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In view of this, the present invention provides a porous niobium carbide MXene/reduced graphene oxide-based heating film to solve the problems of poor thickness controllability, uneven heat production, large sq

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

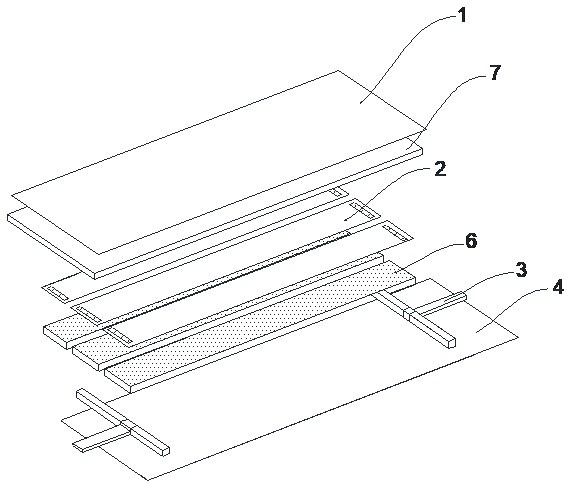

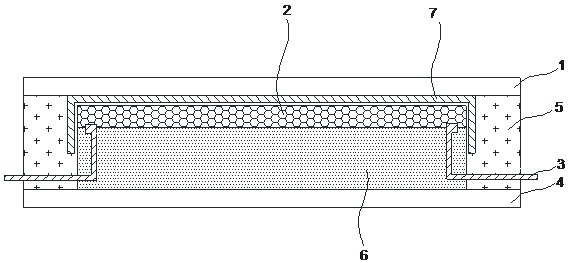

The invention provides a porous niobium carbide MXene/reduced graphene oxide-based heating film which comprises a first transparent insulating layer, a porous niobium carbide MXene/reduced graphene oxide-based conductive film, a second transparent insulating layer and an electrode, and is characterized in that one surface of the porous niobium carbide MXene/reduced graphene oxide-based conductivefilm is covered by the first transparent insulating layer; the other surface of the porous niobium carbide MXene/reduced graphene oxide-based conductive film is covered by the second transparent insulating layer, one end of the electrode is electrically connected with the porous niobium carbide MXene/reduced graphene oxide-based conductive film, and the other end of the electrode extends out of the first transparent insulating layer or the second transparent insulating layer. The porous niobium carbide MXene/reduced graphene oxide-based heating film provided by the invention has excellent electron conduction performance, good flexibility and tensile resistance, and excellent heat conduction performance, infrared emission performance, antibacterial performance and structural stability.

Description

technical field [0001] The invention relates to the technical field of new materials, in particular to a porous niobium carbide MXene / reduced graphene oxide-based heating film. Background technique [0002] With people's longing for a better and healthy life, it is urgent to improve the traditional heating system, find more economical and clean alternative energy sources, and develop a new type of green and low-carbon heating system. The electric heating heating technology based on the infrared emission performance of graphene, that is, the graphene-based infrared heating ink and its infrared heating element technology, provides an effective solution to solve the above problems. Compared with traditional heating methods such as coal burning, steam, hot air and electric resistance, graphene heating has the advantages of fast heating speed, high electric-thermal conversion rate, automatic temperature control, convenient partition control, stable heating, no abnormal noise duri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H05B3/34

CPCH05B3/34

Inventor 吴立刚曹达平马宇飞叶德林李明李正博曾垂彬刘秋明

Owner FOSHAN SHUNDE SANBEI ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com