Porous nano-sheet structure copper-nickel nitride material, preparation method and applications thereof

A nanosheet and nitride technology, applied in chemical instruments and methods, chemical/physical processes, inorganic chemistry, etc., can solve the problems of hydrogen evolution and oxygen evolution overpotentials that need to be further improved, and achieve excellent electrolysis water hydrogen production performance, excellent Durability, mild reaction conditions effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a porous nanosheet structure copper-nickel nitride material supported on carbon fiber cloth, comprising the steps of:

[0029] 1) 1.0mmol Cu(NO 3 ) 2 ·3H 2 O, 2.0mmol Ni(NO 3 ) 2 ·6H 2 O and 5mmol hexamethylenetetramine were dissolved in 60mL methanol solvent and stirred for 20min;

[0030] 2) Set the size to 10cm 2 The carbon fiber cloth was added to the solution obtained in step 2), soaked for 30 minutes, then moved to a 100mL reaction kettle, and heated in water at 180°C for 12 hours;

[0031] 3) Take out the carbon fiber cloth in step 2), wash it three times with deionized water and absolute ethanol, and dry it in an oven at 65°C;

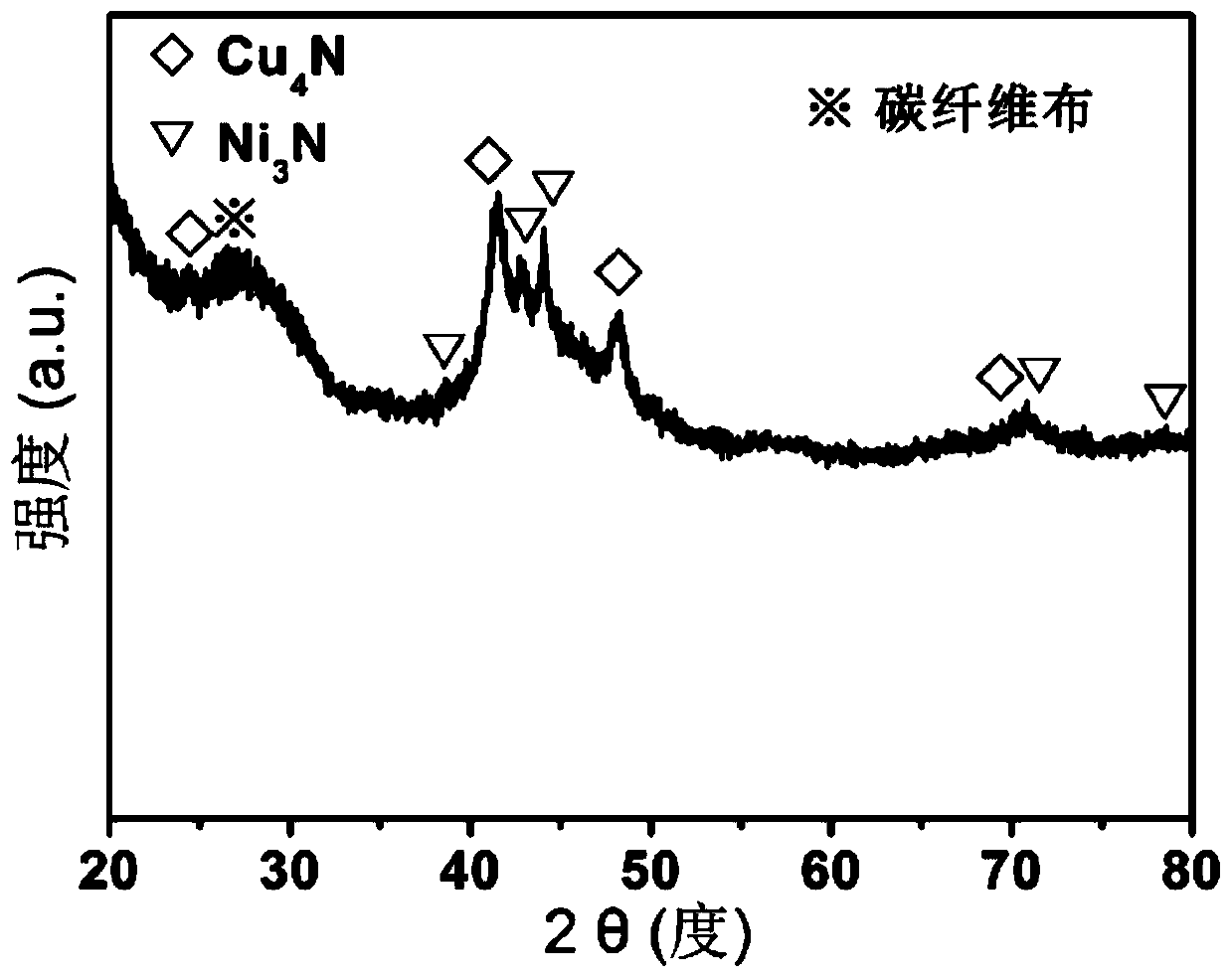

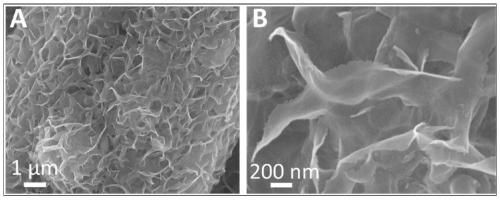

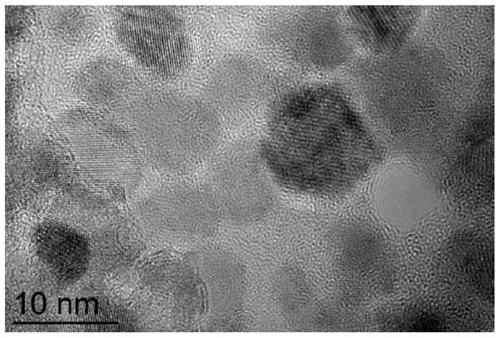

[0032] 4) Put the carbon fiber cloth dried in step 3) in a corundum crucible and place it in a tube furnace with an ammonia gas flow rate of 20 sccm at 5°C min -1 Raise the temperature to 400°C and keep it warm for 2h. After the tube furnace is cooled, the carbon fiber cloth is taken out, and the porous na...

Embodiment 2

[0037] A method for preparing a porous nanosheet structure copper-nickel nitride material supported on carbon fiber cloth, comprising the steps of:

[0038] 1) 1.5mmol Cu(NO 3 ) 2 ·3H 2 O, 1.5mmol Ni(NO 3 ) 2 ·6H 2 O and 6mmol hexamethylenetetramine were dissolved in 70mL methanol solvent and stirred for 20min;

[0039] 2) Set the size to 10cm 2 The carbon fiber cloth was added to the solution obtained in step 2), soaked for 15 minutes, then moved to a 100mL reaction kettle, and heated in water at 180°C for 10 hours;

[0040] 3) Take out the carbon fiber cloth in step 2), wash it three times with deionized water and absolute ethanol, and dry it in an oven at 65°C;

[0041] 4) Put the carbon fiber cloth dried in step 3) in a corundum crucible and place it in a tube furnace with an ammonia gas flow rate of 50 sccm at 5°C min -1 Raise the temperature to 400°C and keep it warm for 2h. After the tube furnace is cooled, the carbon fiber cloth is taken out, and the porous na...

Embodiment 3

[0044] A method for preparing a porous nanosheet structure copper-nickel nitride material supported on carbon fiber cloth, comprising the steps of:

[0045] 1) Add 2mmol Cu(NO 3 ) 2 ·3H 2 O, 1mmol Ni(NO 3 ) 2 ·6H 2 O and 4mmol hexamethylenetetramine were dissolved in 65mL methanol solvent and stirred for 20min;

[0046] 2) Set the size to 10cm 2 The carbon fiber cloth was added to the solution obtained in step 2), soaked for 30 minutes, then moved to a 100mL reaction kettle, and heated in water at 180°C for 12 hours;

[0047] 3) Take out the carbon fiber cloth in step 2), wash it three times with deionized water and absolute ethanol, and dry it in an oven at 65°C;

[0048] 4) Put the carbon fiber cloth dried in step 3) in a corundum crucible and place it in a tube furnace with an ammonia gas flow rate of 40 sccm at 2°C min -1 Raise the temperature to 450°C and keep it warm for 2h. After the tube furnace is cooled, the carbon fiber cloth is taken out, and the porous na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com