Lithium cobalt oxide composite material coated with lithium orthosilicate and carbon, preparation method and application

A technology of composite materials and lithium orthosilicate, which is applied in the preparation/purification of carbon, chemical instruments and methods, silicates, etc., can solve problems such as poor cycle stability, prevent side reactions, good electronic conductivity, and improve The effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] S5, mixed precursor: 4.8g tricobalt tetroxide and 2.3g lithium carbonate were evenly mixed, and ground for 2 hours to obtain a uniformly mixed precursor;

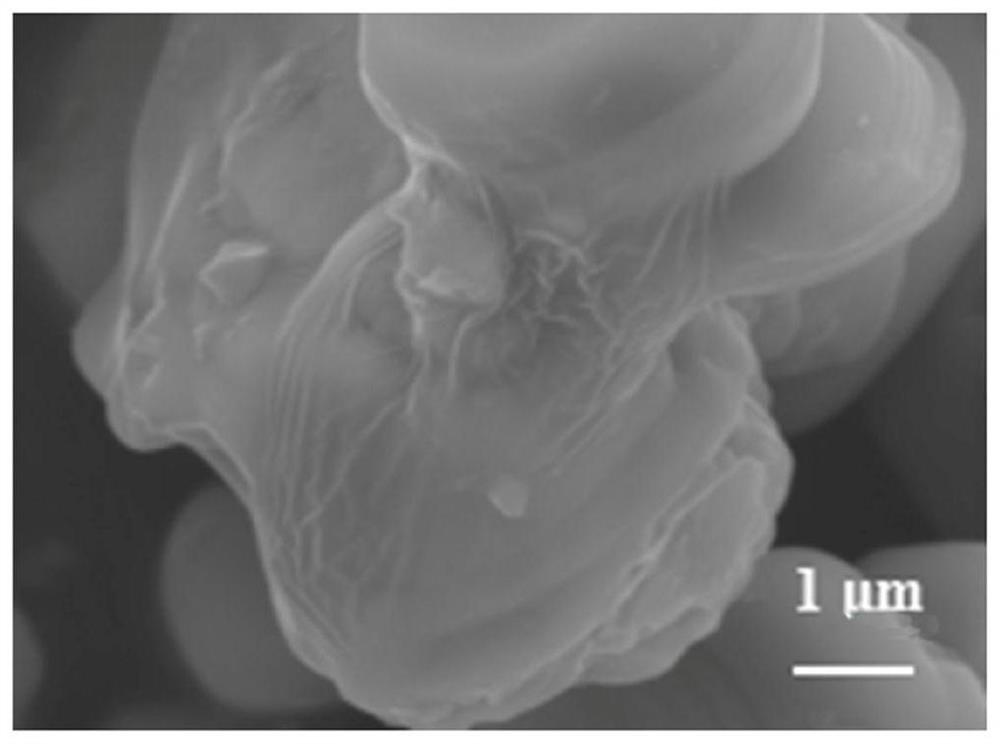

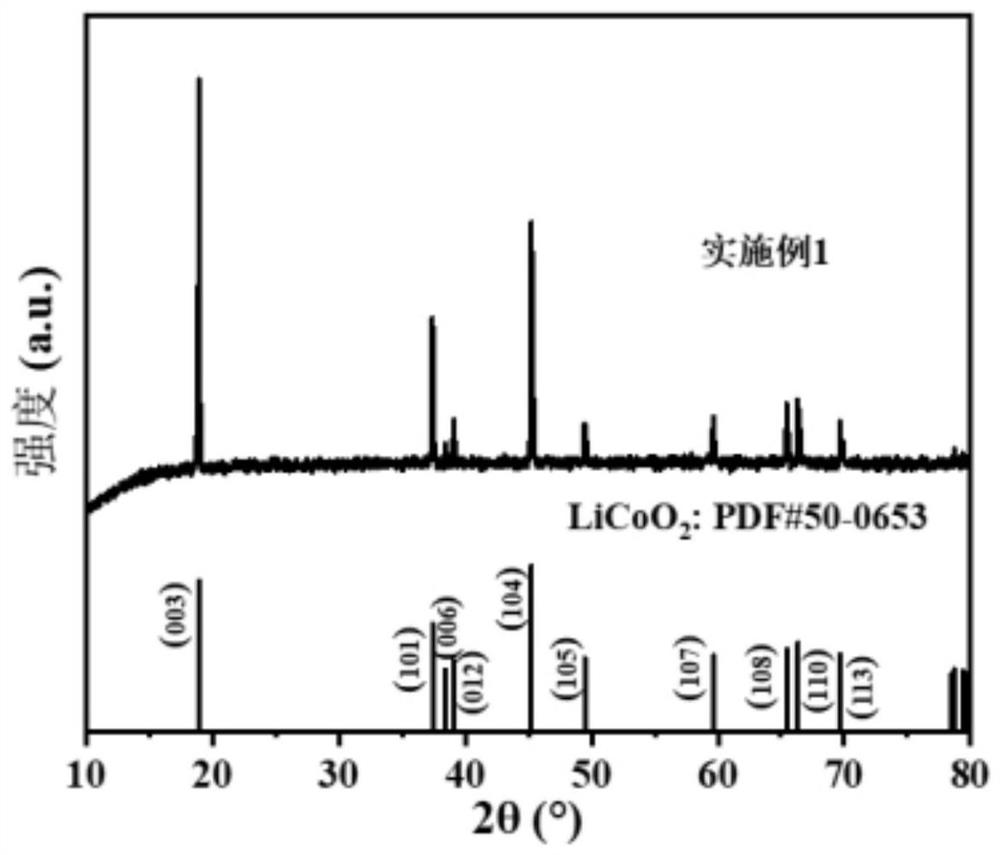

[0049] S6. Sintering reaction: heat-treat the homogeneously mixed precursor of S5 at 1050°C in an air atmosphere for 10 hours, the heating and cooling rates are both 5°C / min, and after cooling to room temperature, grind and sieve to obtain a powdery material;

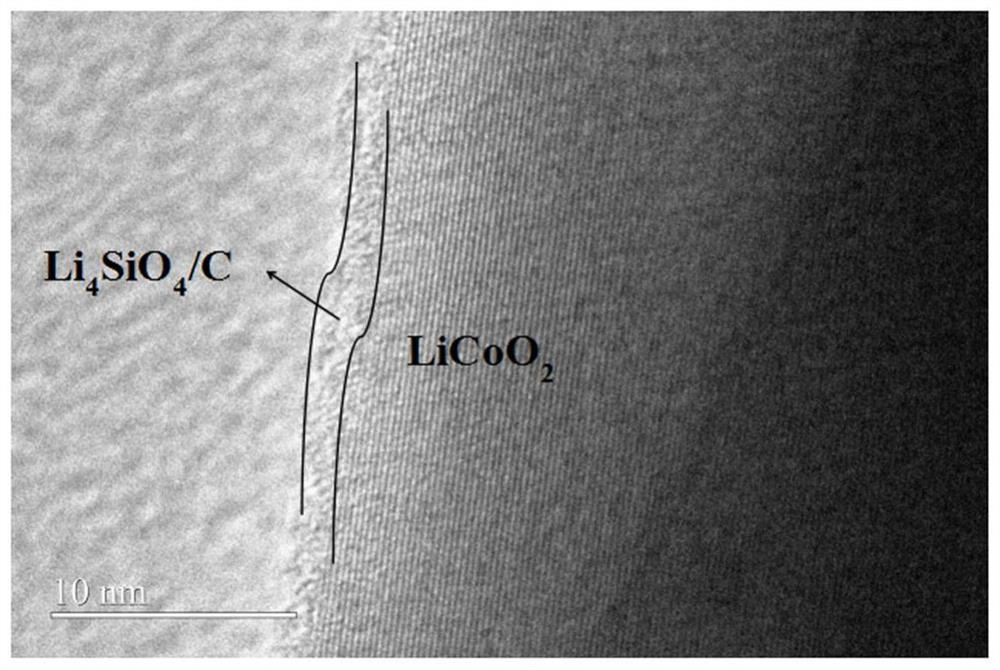

[0050] S7, preparation of coating layer precursor: preparation of coating layer precursor: dissolve 0.3g liquid acrylonitrile low polymer in 100mL deionized water, stir evenly, then add 0.0425g tetraethyl silicate and 0.034g Lithium hydroxide monohydrate and ultrasound to obtain a mixed solution; take 2 g of the powder obtained in S6 and add it to the above solution; first stir at room temperature for 10 h, then heat and stir at 60 ° C until the solvent is evaporated to dryness, and obtain carbon source, silicon source, Lithium cobalt oxide powder evenly coate...

Embodiment 2

[0061] S9, mixed precursor: 4.8g tricobalt tetroxide and 2.3g lithium carbonate were evenly mixed, and ground for 2 hours to obtain a uniformly mixed precursor;

[0062] S10, sintering reaction: heat-treat the homogeneously mixed precursor of S9 in an air atmosphere at 1050°C for 10 hours, the heating and cooling rates are both 5°C / min, and grind to obtain a powdery material;

[0063] S11, preparation of coating layer precursor: preparation of coating layer precursor: dissolve 0.3g liquid acrylonitrile low polymer in 100mL deionized water, stir well, then add 0.085g tetraethyl silicate and 0.068g Lithium hydroxide monohydrate and ultrasound to obtain a mixed solution; take 2 g of the powder obtained in S10 and add it to the above solution; first stir at room temperature for 10 hours, and then stir at 60 ° C until the solvent is evaporated to dryness to obtain carbon source, silicon source, lithium Source uniformly coated lithium cobalt oxide powder;

[0064] S12. Secondary si...

Embodiment 3

[0066] S13, mixed precursor: uniformly mixed 4.8g of tricobalt tetroxide and 2.3g of lithium carbonate, and ground for 2 hours to obtain a uniformly mixed precursor;

[0067] S14, sintering reaction: heat-treat the homogeneously mixed precursor of S13 in an air atmosphere at 1050°C for 10 hours, the heating and cooling rates are both 5°C / min, and grind to obtain a powdery material;

[0068] S15, preparation of coating layer precursor: preparation of coating layer precursor: dissolve 0.3g liquid acrylonitrile low polymer in 100mL deionized water, stir evenly, then add 0.1275g tetraethyl silicate and 0.102g Lithium hydroxide monohydrate and ultrasound to obtain a mixed solution; take 2 g of the powder obtained in S14 and add it to the above solution; first stir at room temperature for 10 hours, and then stir at 60°C until the solvent evaporates to dryness to obtain carbon source, silicon source, lithium Source uniformly coated lithium cobalt oxide powder;

[0069] S16. Secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com