A kind of soybean harvesting device for mountain

A harvesting device and soybean technology, which is applied to harvesters, applications, agricultural machinery and implements, etc., can solve the problems of low harvesting efficiency, uncertain slope, and inability of harvesters to work, and achieve the effect of convenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

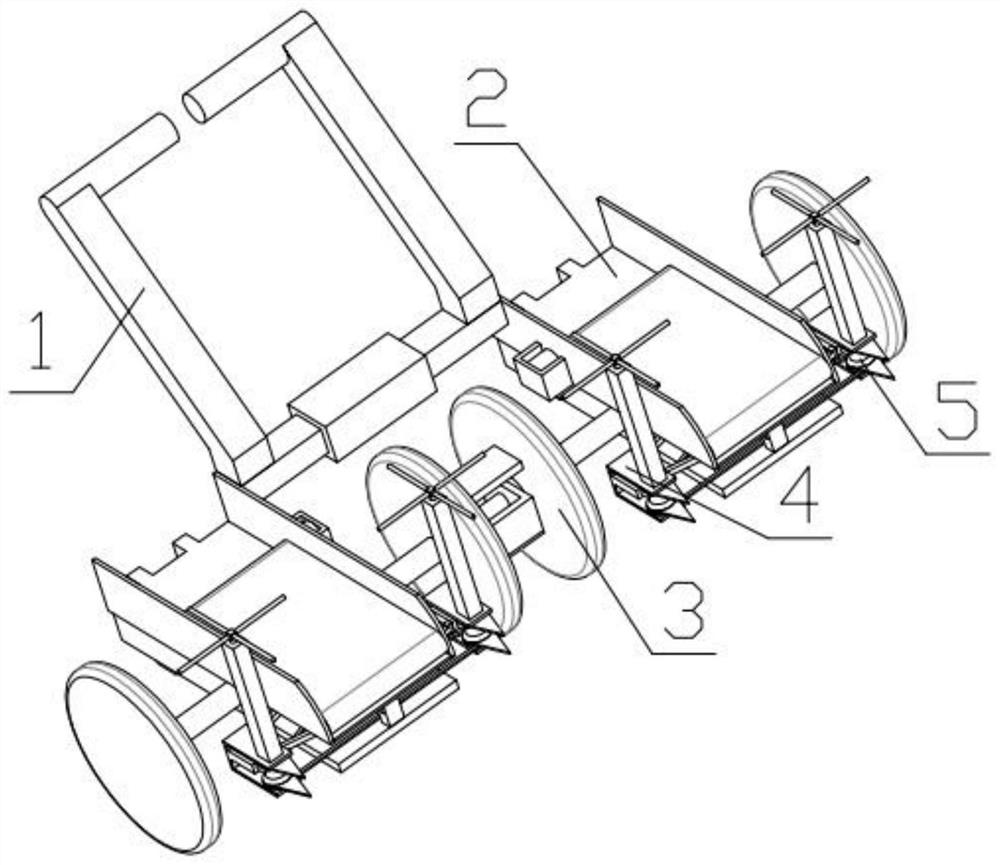

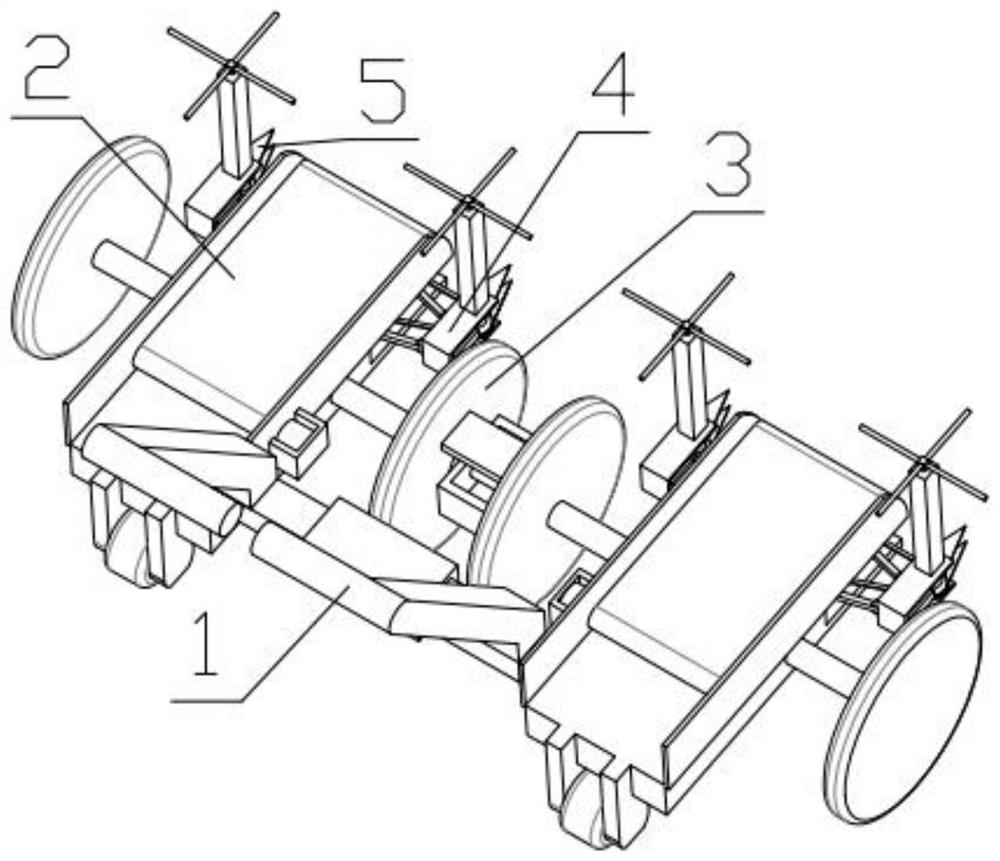

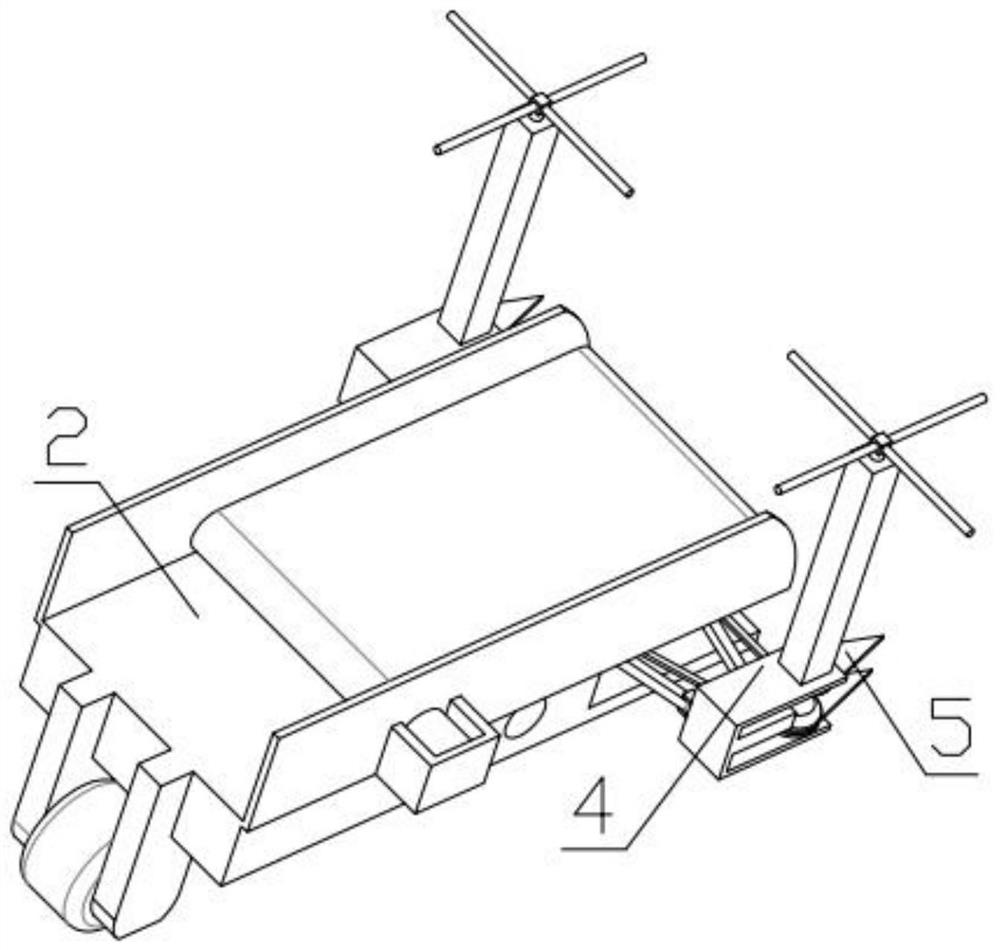

[0037] Combine below Figure 1-18 Description of this embodiment, a soybean harvesting device for mountainous areas, including a telescopic handrail assembly 1, a transmission mechanism 2, a moving mechanism 3, a spacing adjustment mechanism 4 and a cutting mechanism 5, and the two sides of the telescopic handrail assembly 1 are fixedly installed respectively The transmission mechanism 2, the moving mechanism 3 is fixedly installed on the transmission mechanism 2, the distance adjustment mechanism 4 is fixedly installed on the transmission mechanism 2, and the cutting mechanism 5 is fixedly installed on the distance adjustment mechanism 4.

specific Embodiment approach 2

[0038] Combine below Figure 1-18 Describe this embodiment, this embodiment will further explain the first embodiment, the telescopic armrest assembly 1 includes a single-side armrest 1-1, a square tube 1-2, a support spring 1-3, and the single-side armrest 1-1 is slidably installed In the groove provided on the square cylinder 1-2, one end of the support spring 1-3 is fixedly installed on the one-sided armrest 1-1, and the other end of the support spring 1-3 is fixedly installed on the concave groove on the square cylinder 1-2. in the slot.

specific Embodiment approach 3

[0039] Combine below Figure 1-18 Describe this embodiment, this embodiment will further explain the second embodiment, the transmission mechanism 2 includes a comprehensive installation base plate 2-1, auxiliary wheels 2-2, transmission motor 2-3, conveyor belt 2-4, the first shaft 2-5, the second shaft 2-6, the auxiliary wheel 2-2 is rotatably installed in the groove provided on the comprehensive installation base plate 2-1, the transmission motor 2-3 is fixedly installed on the comprehensive installation base plate 2-1, the transmission motor The output end of 2-3 is fixedly installed with the first shaft 2-5, the other end of the first shaft 2-5 is rotatably installed in the groove provided on the comprehensive installation base plate 2-1, and the second shaft 2-6 is rotatably installed in the In the groove provided on the comprehensive installation base plate 2-1, the conveyor belt 2-4 is engaged with the first shaft 2-5 and the second shaft 2-6, and the comprehensive ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com