Pavement maintenance device and maintenance method

A maintenance device and sub-assembly technology, applied in the direction of roads, roads, road repair, etc., can solve the problems of road maintenance efficiency and the impact of traffic jam time, and achieve the effect of saving the number of jobs, facilitating height adjustment, and maintaining balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

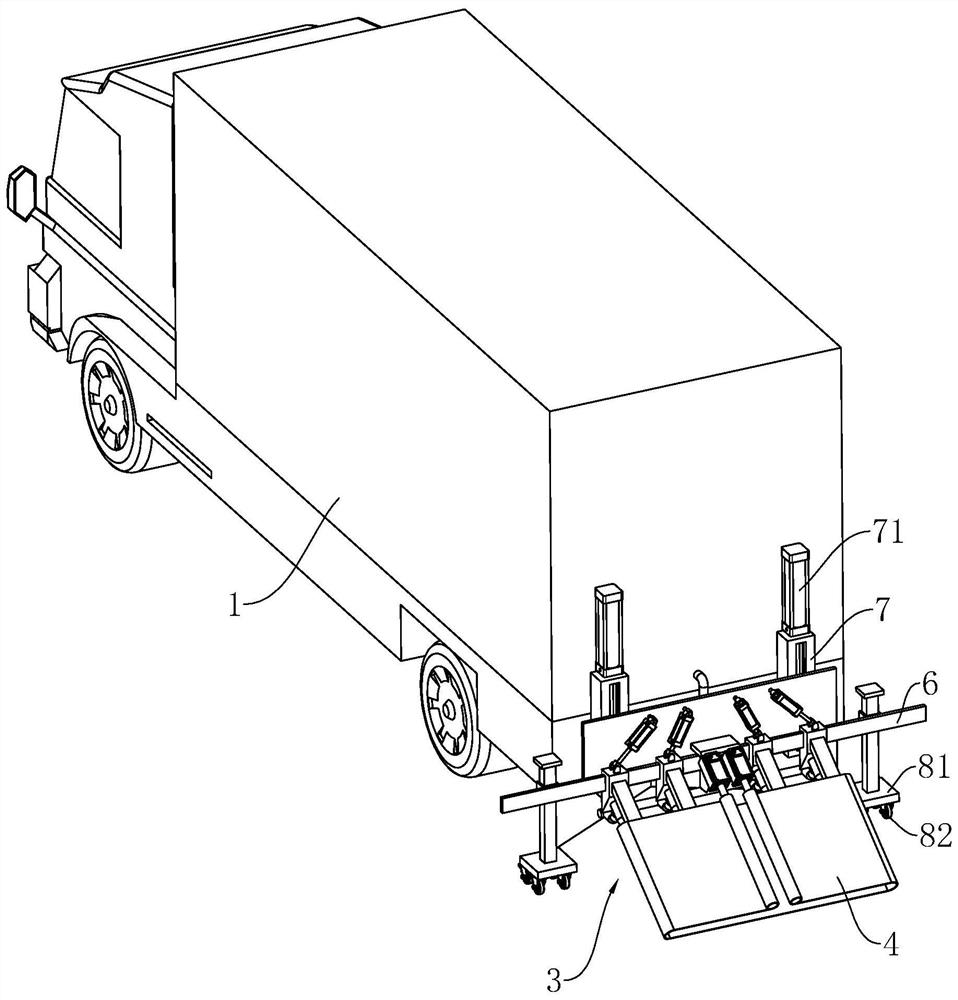

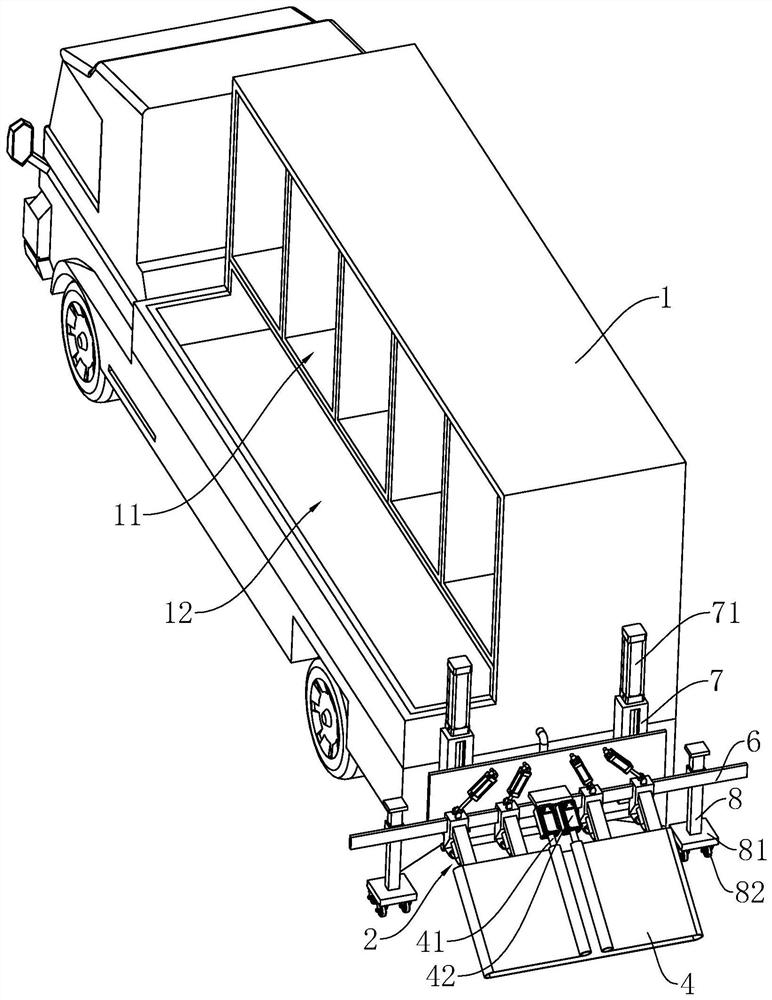

[0042] The following is attached Figure 1-4 The application is described in further detail.

[0043] The embodiment of the present application discloses a road maintenance device. refer tofigure 1 and figure 2 , a road surface maintenance device, comprising a car body 1, five sub-loading buckets 11 are arranged in the car body 1, and the five sub-loading buckets 11 are respectively filled with slurry materials such as emulsified asphalt, aggregates, water, fillers, additives, etc. , the bottom of the car body 1 is also provided with a mixing bucket 12, and the five sub-loading buckets 11 are all communicated with the mixing bucket 12, and the corresponding slurry raw materials are discharged into the mixing bucket 12, and various slurry raw materials are in the mixing bucket 12. Mix evenly to form a thin slurry in the required ratio.

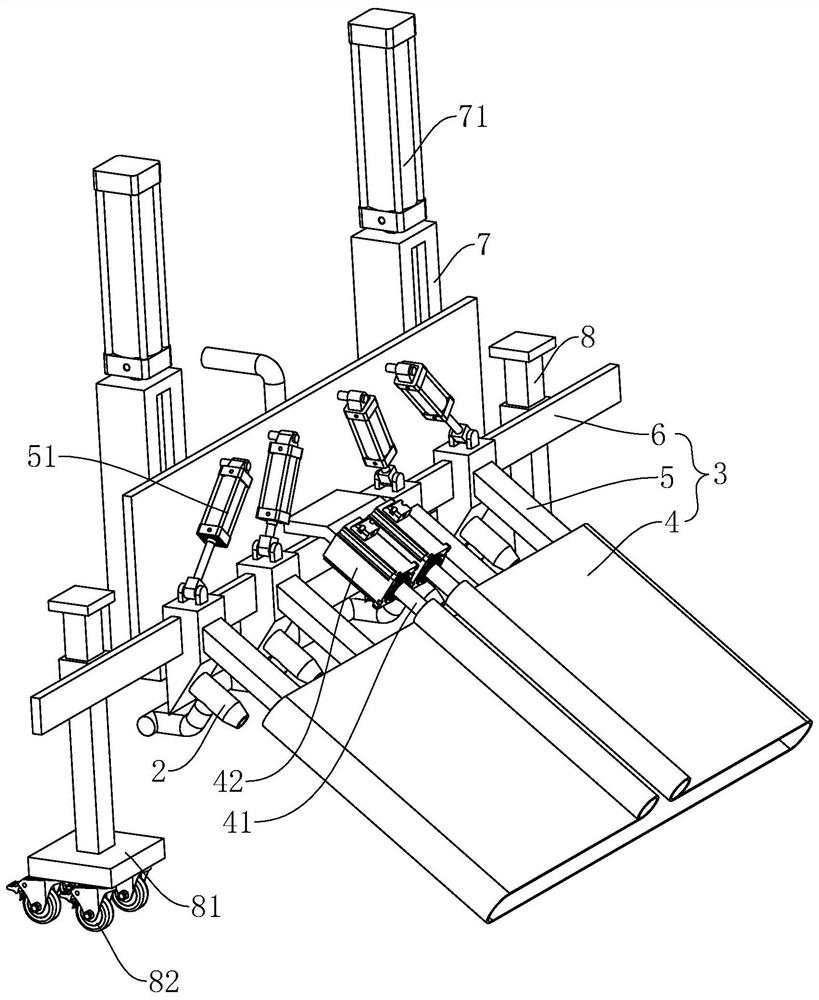

[0044] refer to figure 2 and image 3 , the rear of the car body 1 is provided with a scraping assembly 3 and two vertically arranged v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com