Double-seal wear-resistant valve

A wear-resistant, double-sealing technology, applied to valve details, valve devices, valve housing structures, etc., can solve problems such as moss spreading and ball sealing degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

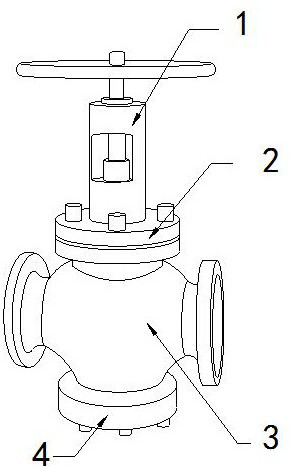

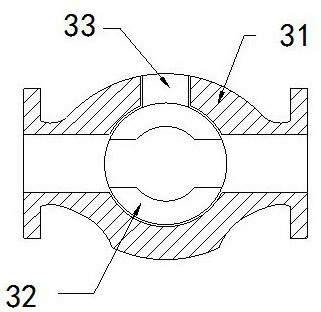

[0026] For example Figure 1-Figure 5 Shown:

[0027] The invention provides a double-seal wear-resistant valve, the structure of which includes a control end 1, a connecting block 2, a valve body 3, and a connecting seat 4. The control end 1 is installed at the upper end of the connecting block 2, and the connecting block 2 Fixed on the upper end of the valve body 3, the valve body 3 and the connecting seat 4 are an integrated structure; the valve body 3 includes a shell 31, a ball 32, and a linkage shaft 33, and the ball 32 is movably engaged with the shell 31 In the inner position, the linkage shaft 33 passes through the shell 31 and is connected with the upper end of the ball 32 .

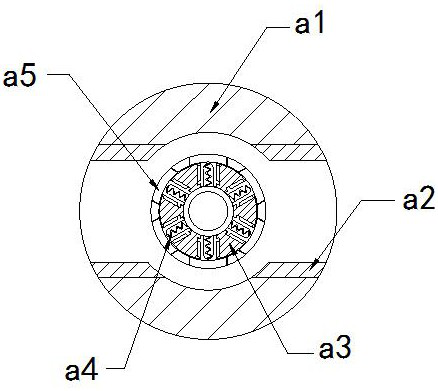

[0028] Wherein, the sphere 32 includes an outer frame a1, an inner frame a2, a ring body a3, a reset bar a4, and a clearing mechanism a5, the inner frame a2 and the outer frame a1 are an integrated structure, and the ring body a3 and the outer frame a1 The middle part of the clearing mechanis...

Embodiment 2

[0034] For example Figure 6-Figure 8 Shown:

[0035] Wherein, the built-in frame a2 includes a frame c1, a force plate c2, and a reset piece c3, the force plate c2 is movably engaged with the inner side of the frame c1, and the reset piece c3 is embedded and fixed in the force plate c2 and the frame c1 Between them, there are two stress plates c2, which are evenly distributed symmetrically on the inner walls of the upper and lower sides of the frame c1, and the force plate c2 can be pushed inward by the extrusion of the water flow on the stress plate c2. shrink.

[0036] Wherein, the stressed plate c2 includes a plate surface c21, a connecting rod c22, an outer pushing plate c23, and a sleeve frame c24. The lower end position of the sleeve frame c24, the sleeve frame c24 is movably engaged with the connecting rod c22, through the inertial force generated by the reset of the mechanism, the pusher plate c23 can slide downward along the connecting rod c22 under the cooperation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com