A guard wire recovery device based on the inherent characteristics of metal

A technology with inherent characteristics and recycling devices, which is applied in the field of guard rail recycling devices, can solve problems such as potential safety hazards, low efficiency, broken wires of guard rails, etc., and achieve the effect of reducing potential safety hazards and improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

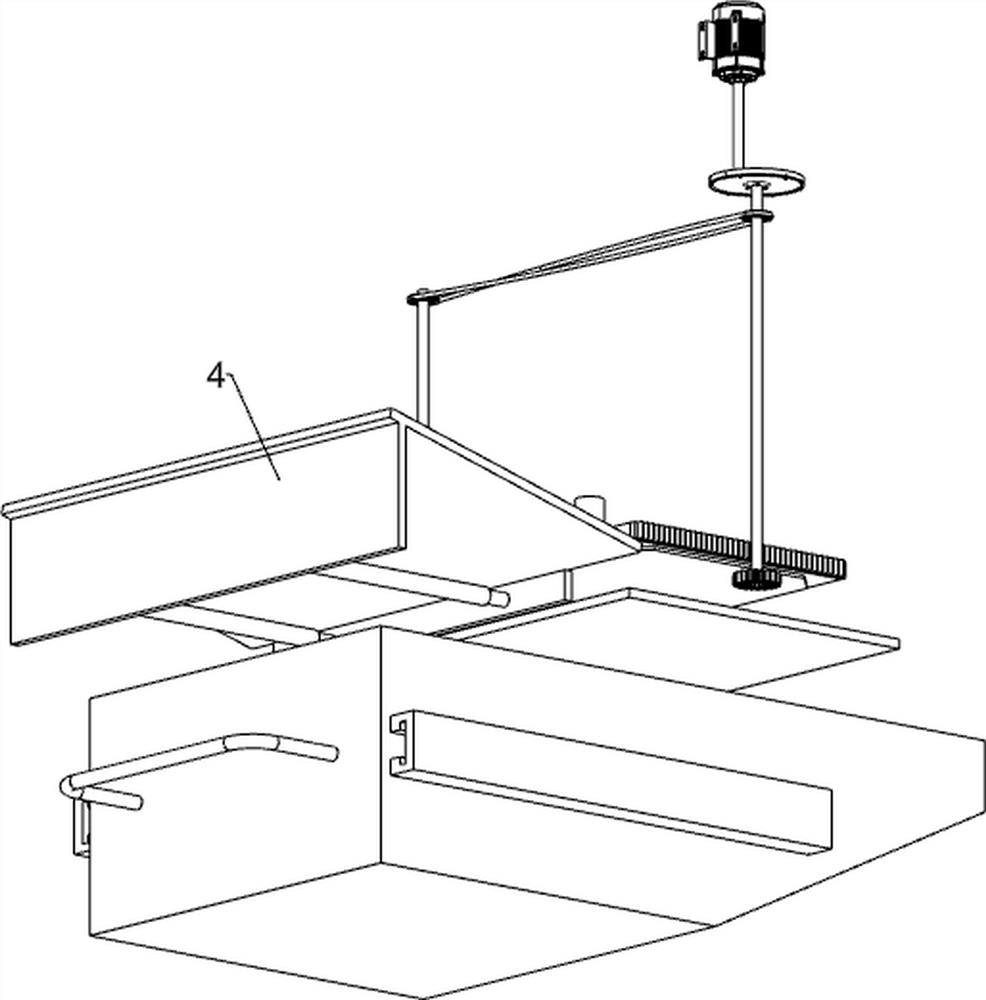

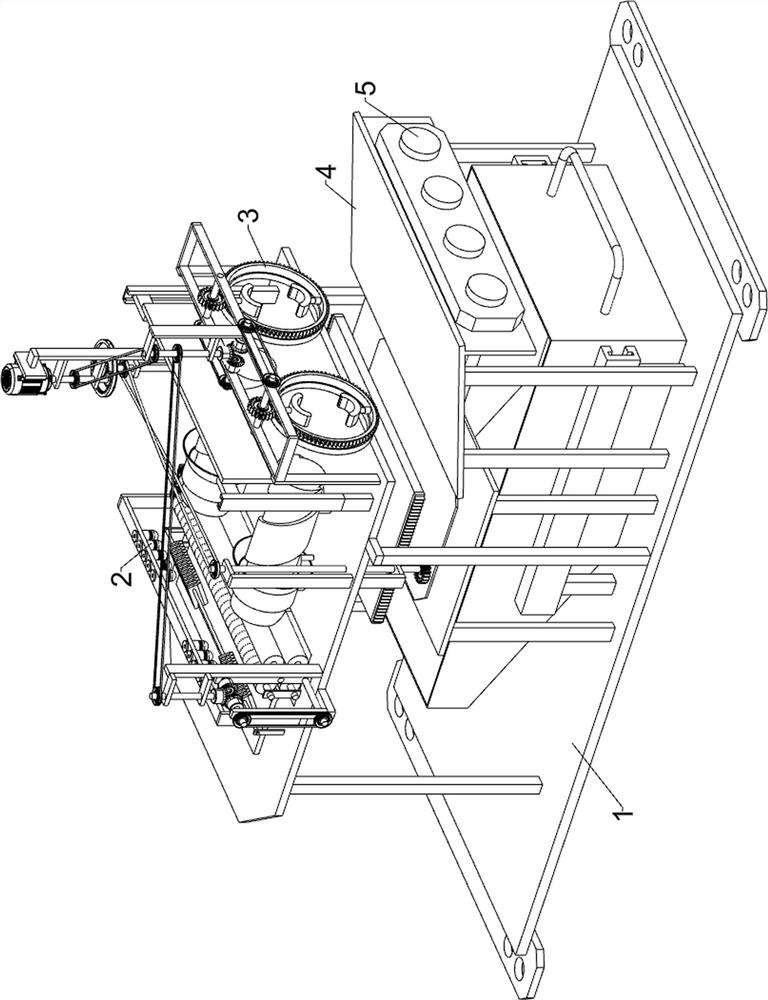

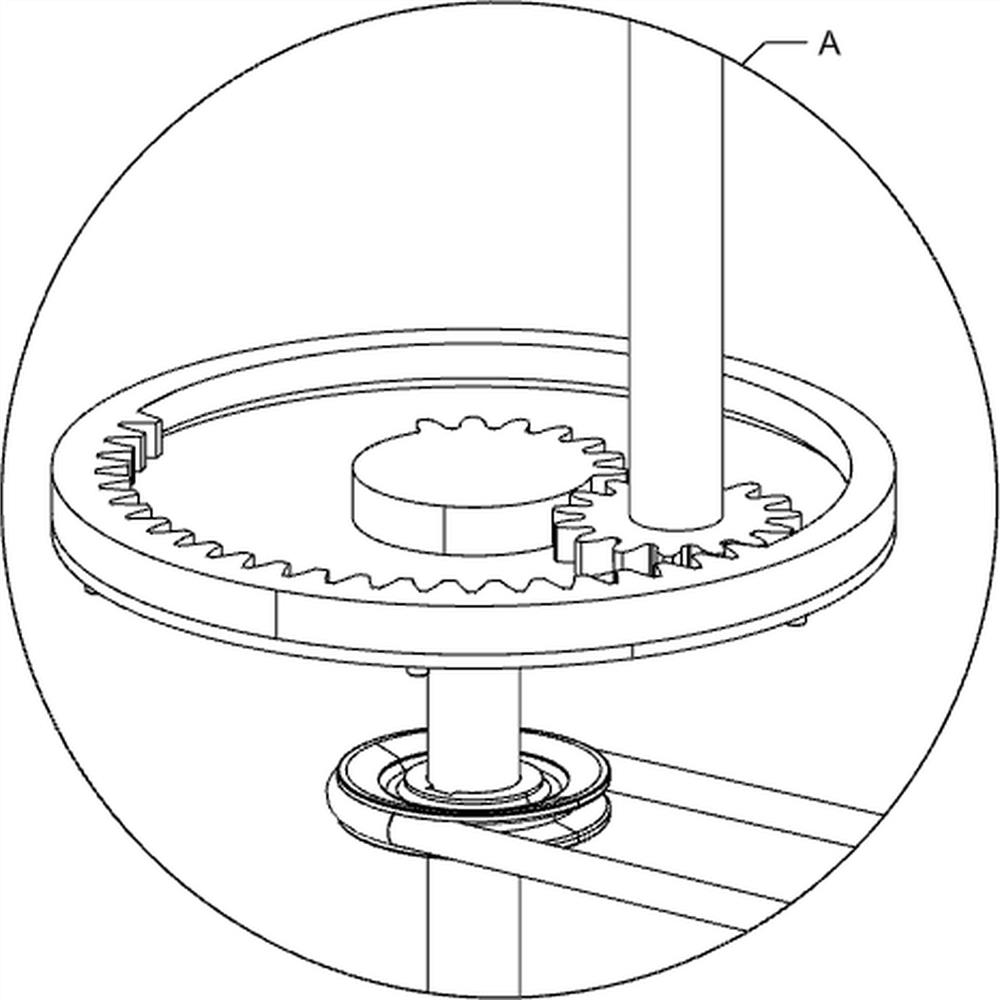

[0030] A grommet recovery device based on the inherent properties of metal, such as Figure 1-8 As shown, it includes a base frame 1, a flattening and separating assembly 2, a rotating diffusion assembly 3, a friction separating assembly 4 and a control button 5; the base frame 1 is connected with the flattening and separating assembly 2; the base frame 1 is connected with the rotating diffusion assembly 3 The chassis 1 is connected with the friction separation assembly 4; the flattened separation assembly 2 is connected with the rotating diffusion assembly 3; the rotating diffusion assembly 3 is connected with the friction separation assembly 4;

[0031] When preparing for work, fix the device on the workbench, insert both ends of the guard strip into the flattening and separating assembly 2, and the flattening and separating assembly 2 on the bottom frame 1 fix the heads at both ends of the guard strip, turn on the power, Then the control button 5 is manipulated and the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com