Resistor device and method for producing resistor device

A manufacturing method and technology of resistors, applied in the direction of resistors, thick film resistors, resistor parts, etc., can solve problems such as solder cracks, peeling of substrates and heat sinks, etc., to prevent peeling, excellent heat resistance, The effect of suppressing bending stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

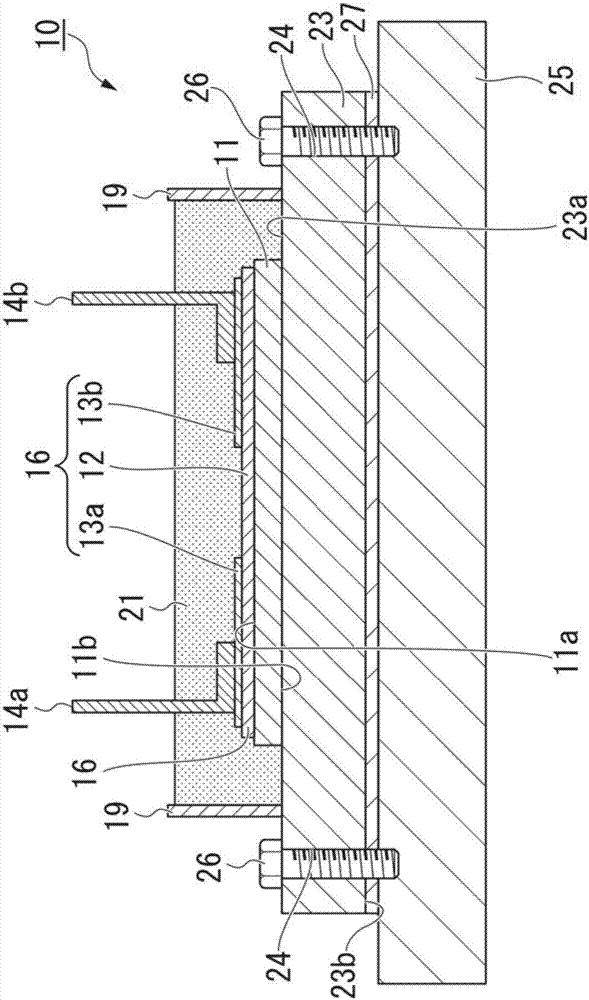

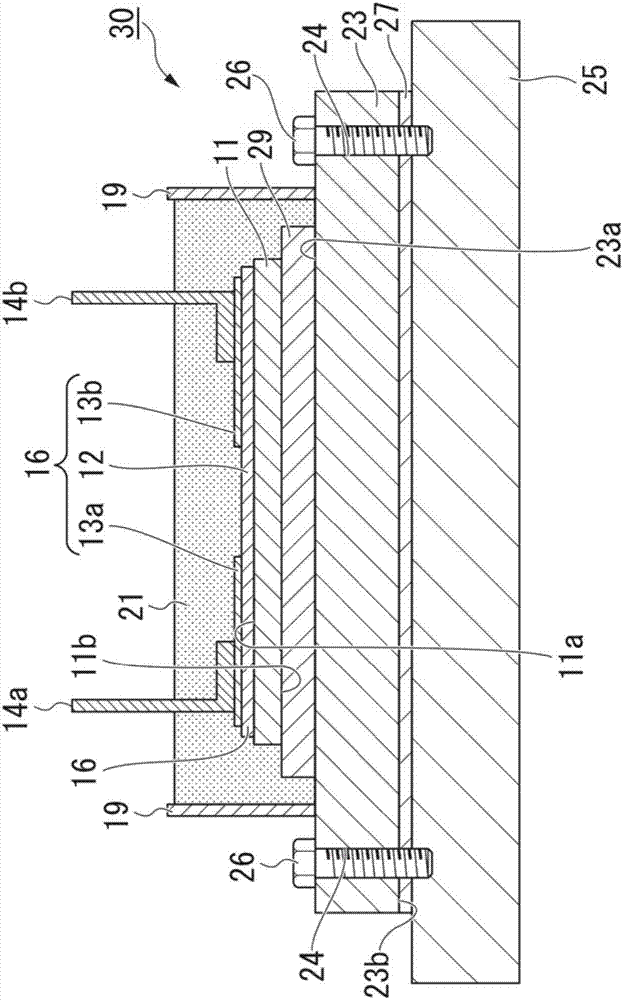

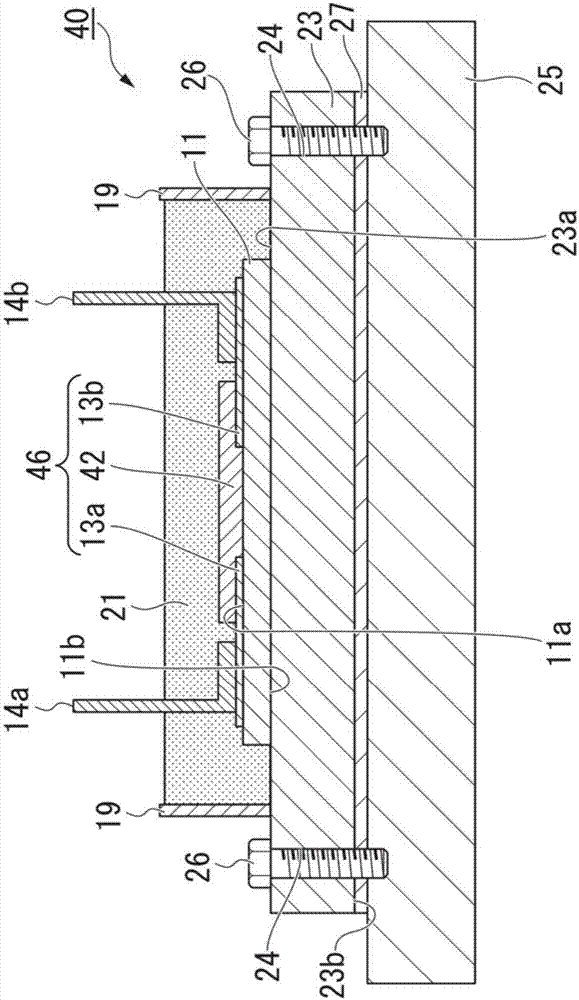

Examples

Embodiment

[0153] Hereinafter, the result of the confirmation experiment performed to confirm the effect of the present invention will be described.

[0154] (Inventive Examples 1 to 5)

[0155] On one side of a ceramic substrate (15 mm×11 mm×0.635 mmt) made of AlN, a Ta-Si resistor element (10 mm×10 mm×0.5 μm) was formed by a sputtering method. Next, after forming Cu films on both ends of the resistance element by sputtering, Cu electrodes (2 mm×10 mm) with a thickness of 1.6 μm were formed by electroplating. Next, on the other side of the ceramic substrate, a heat sink (20mm×13mm×3mmt) made of Al alloy (A1050) is laminated via Al-Si based solder foil, and the welding pressure is increased to 3kgf / cm in the lamination direction 2 , In a vacuum atmosphere, kept at 645°C for 30 minutes, and bonded the ceramic substrate and the heat sink with Al-Si brazing filler metal. In addition, the opposite surface of the heat sink is corrected to a predetermined degree of curvature (amount of warpage) by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com