Substrate processing device

A substrate processing device and substrate technology, applied in the direction of transportation and packaging, conveyor objects, electrical components, etc., can solve the problems of non-floating substrates and increased device costs, and achieve the effects of preventing fracture and suppressing bending stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 approach

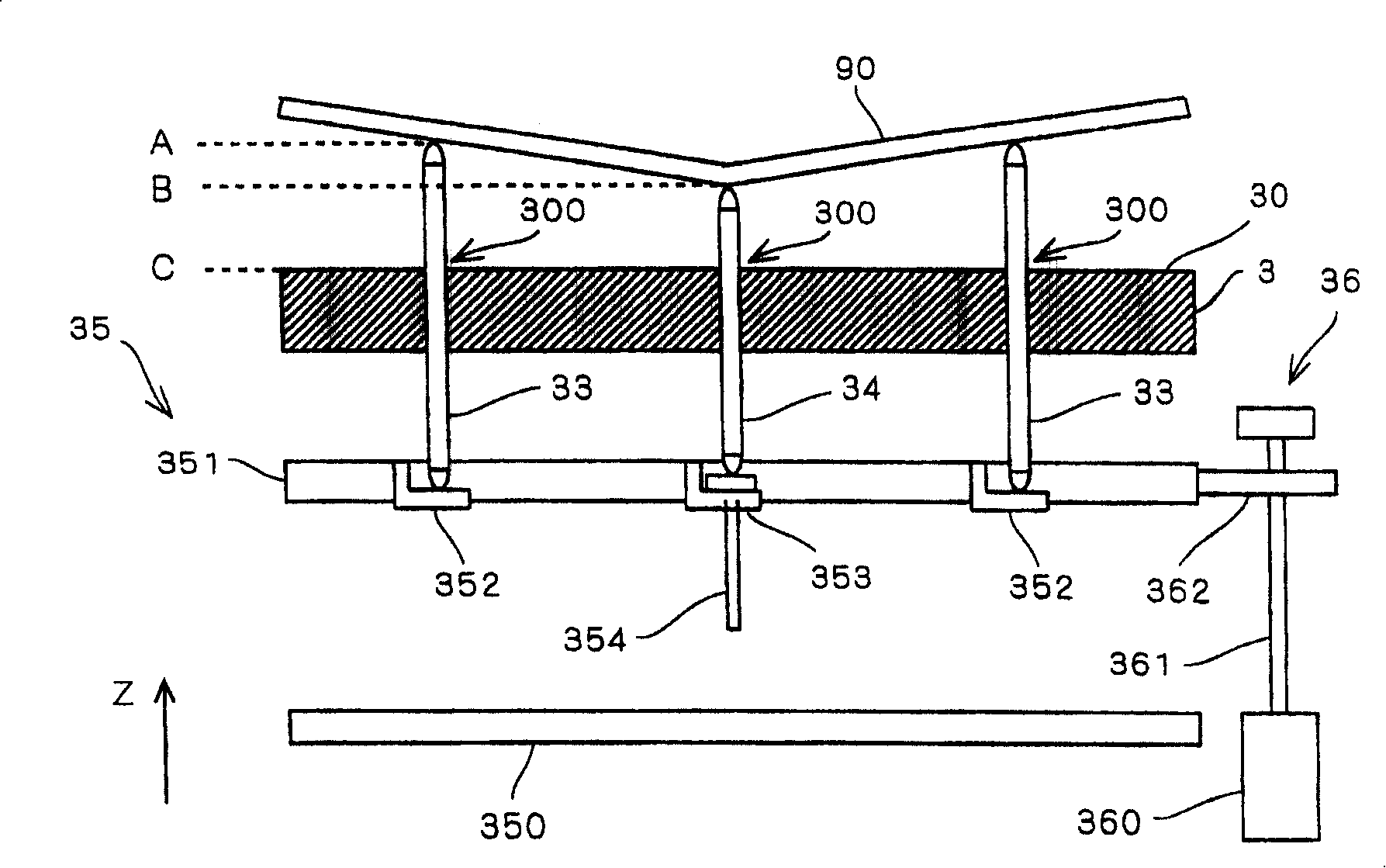

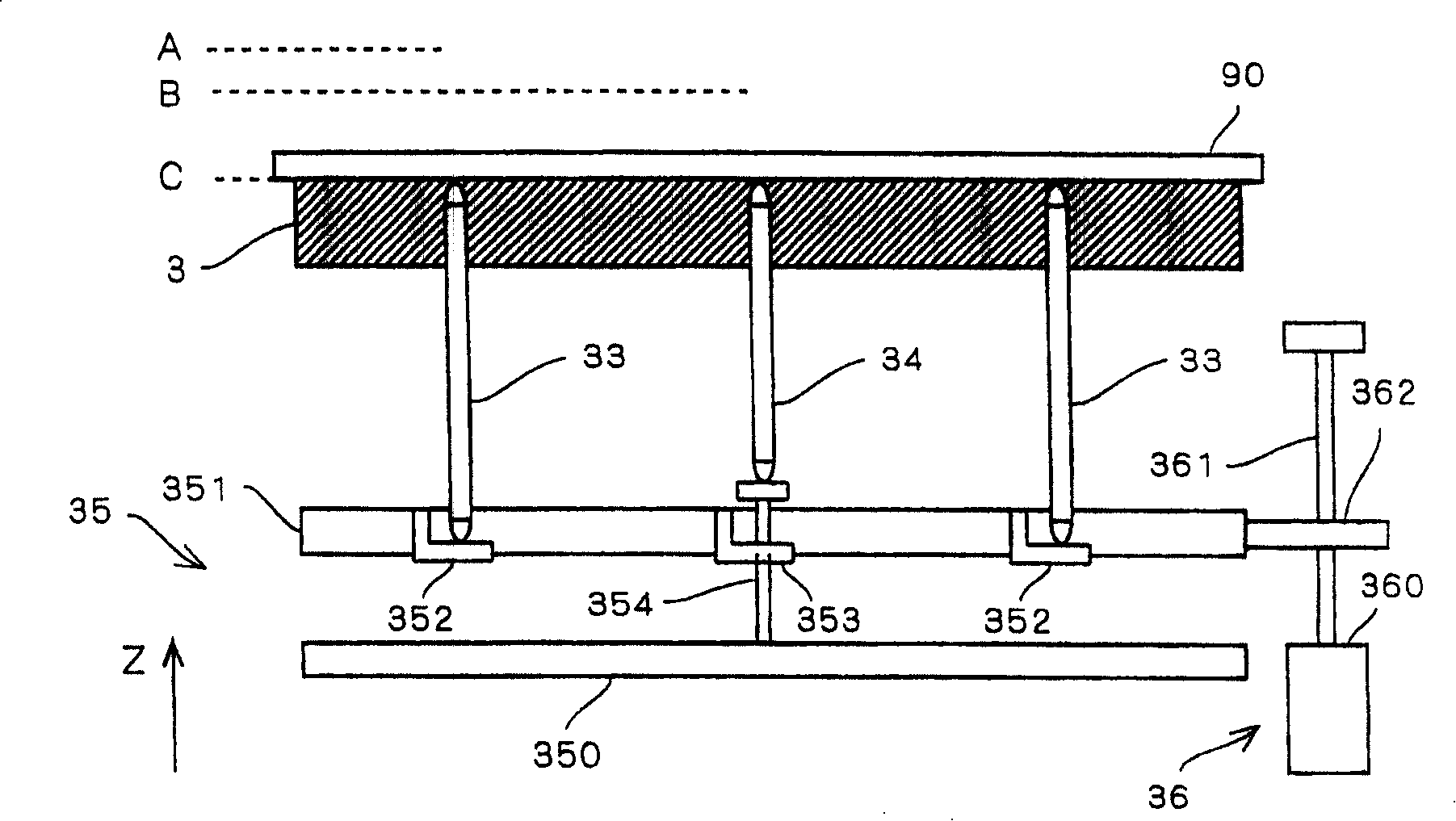

[0117] In the first embodiment, an example in which the raising and reinforcing member 354 and the fixing plate 350 are formed of different members and separated from the raising and reinforcing member 354 and the fixing plate 350 at the raised position has been described, but the fixing plate 350 may also have a raised reinforcing The function of component 354.

[0118] Figure 6 It is a figure which shows the state which supports the 1st support pin 33 and the 2nd support pin 34b at the raised position by the pin support mechanism 35b of the substrate processing apparatus 1b in 3rd Embodiment. in addition, Figure 7 It is a figure which shows the state in which the pin support mechanism 35b supports the 1st support pin 33 and the 2nd support pin 34b at a lowered position.

[0119] The pin support mechanism 35b of 3rd Embodiment has the fixing plate 350a which formed the pin-shaped raising reinforcement member 350b. The raising reinforcing member 350b is formed in a protru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com