Electric manufacturing device for power transformer sealing gasket

A technology for a power transformer and a manufacturing device, applied in metal processing and other directions, can solve the problems of shortening the sealing gasket time, shortening the maintenance period, low processing quality, etc., and achieve the effects of shortening the production time, shortening the maintenance period and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with accompanying drawing:

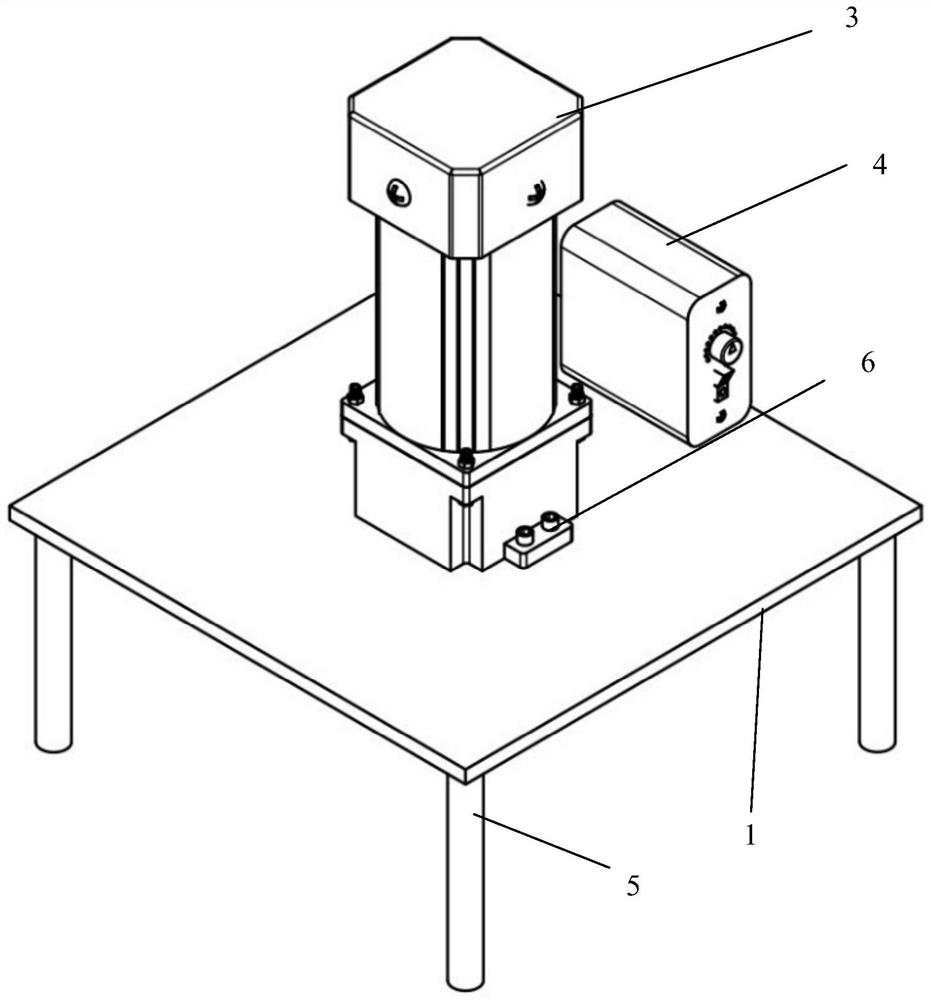

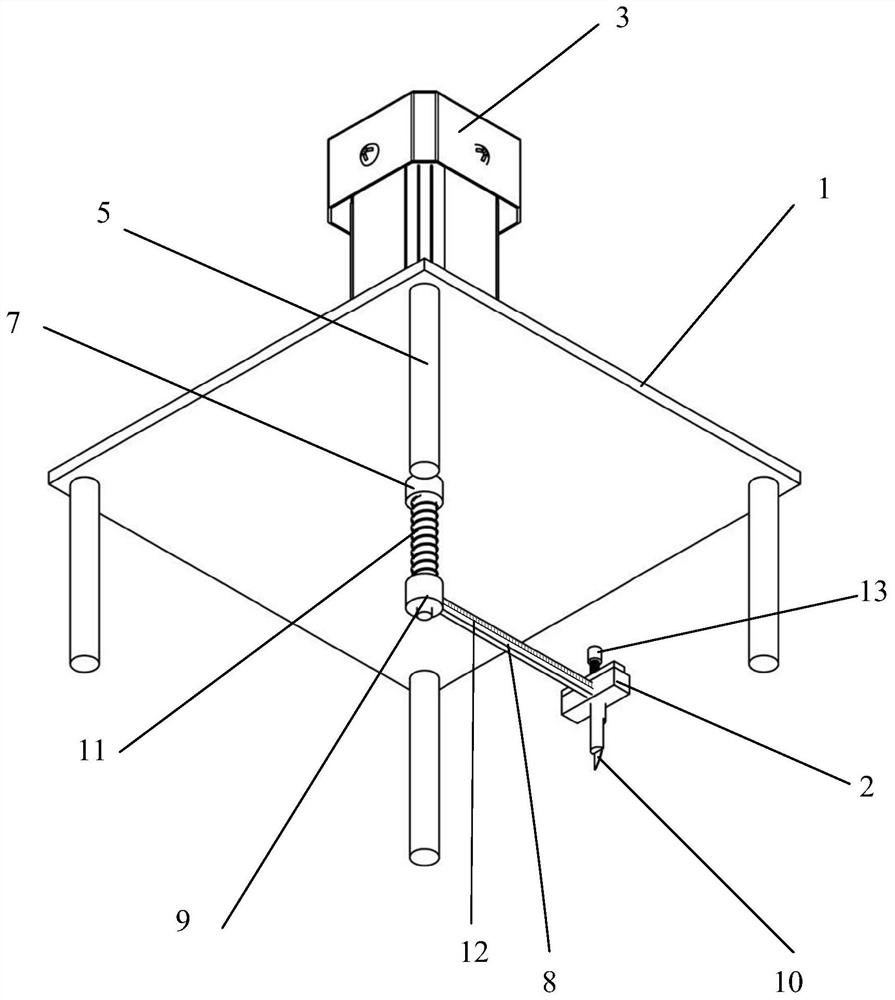

[0021] see figure 1 and figure 2 , an electric manufacturing device for a power transformer gasket, comprising a base plate 1, a machine shaft, a tool holder 2, a motor 3, a switch and a governor 4, the base plate 1 is rectangular, and the lower part is provided with a leg 5, and the leg 5 Four cylindrical steel bars are located at the four corners of the lower side of the rectangular bottom plate 1, the center of the lower side of the bottom plate 1 is provided with a machine shaft, and the center of the upper side of the bottom plate 1 is provided with a motor 3, and the motor 3 is fixed on the bottom plate by fixing bolts 6. The main shaft is coaxially connected with the crankshaft of the motor 3, and a switch and a governor 4 are arranged on the side of the bottom plate 1, and are connected with the motor 3 through a power line.

[0022] The shaft is divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com