Double-self-locking stroke continuously adjustable type high-precision micro-opening-distance foaming mold

A foaming mold, adjustable technology, applied in the field of double self-locking stroke continuous adjustable high-precision micro-opening foaming mold, can solve the problems of low foaming rate, product thickness difference, etc., to avoid low foaming rate or oversized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments, but the scope of implementation of the present invention is not limited thereto.

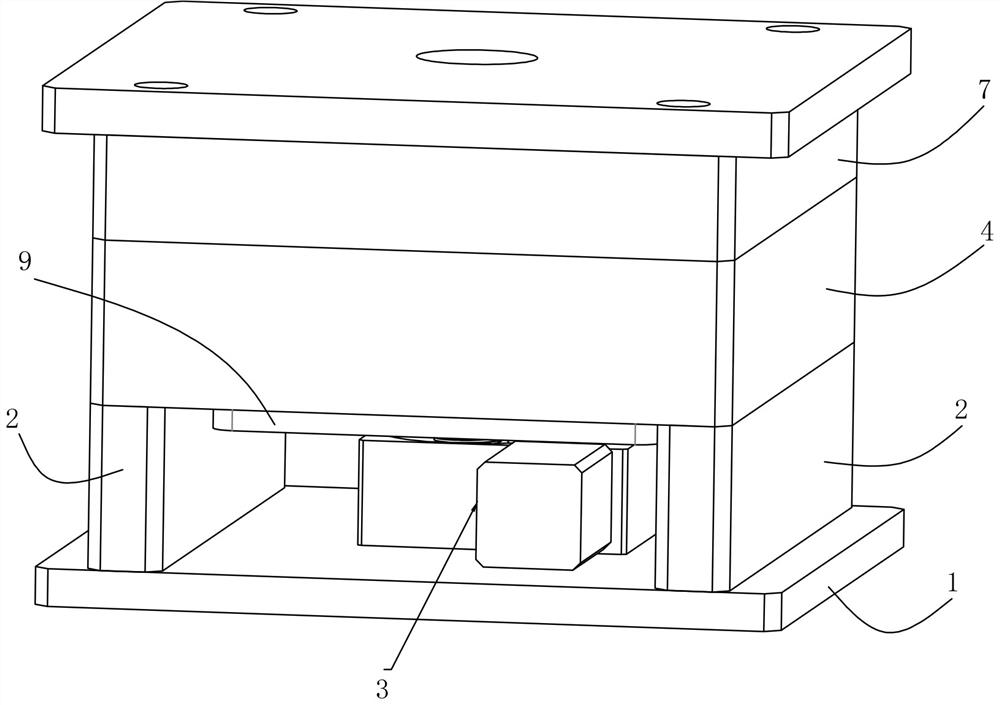

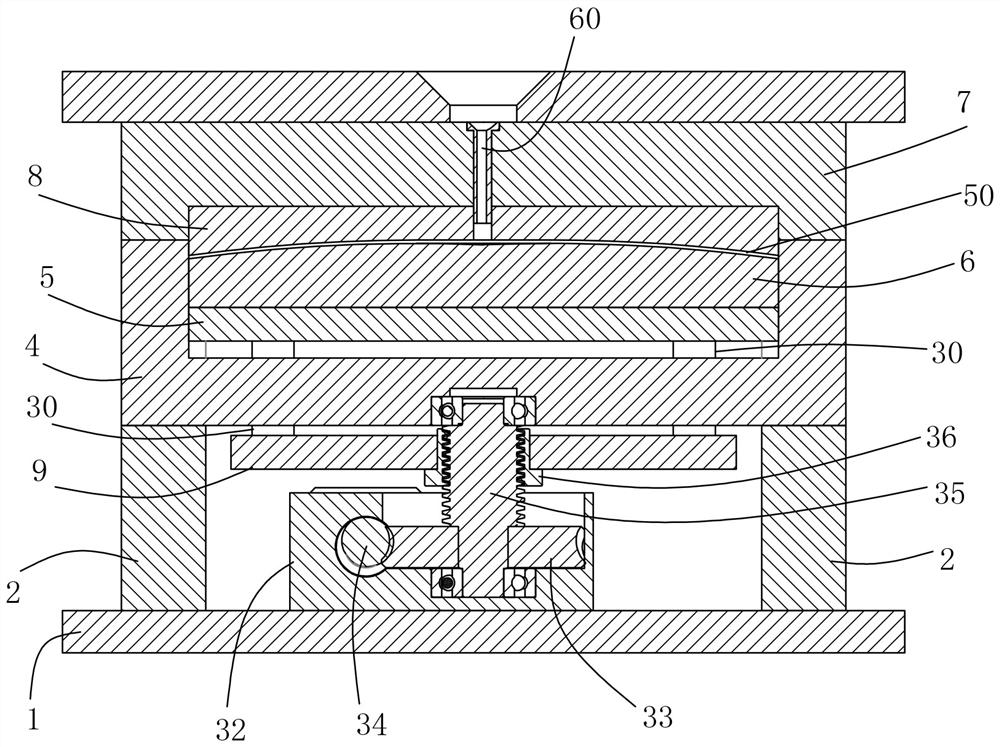

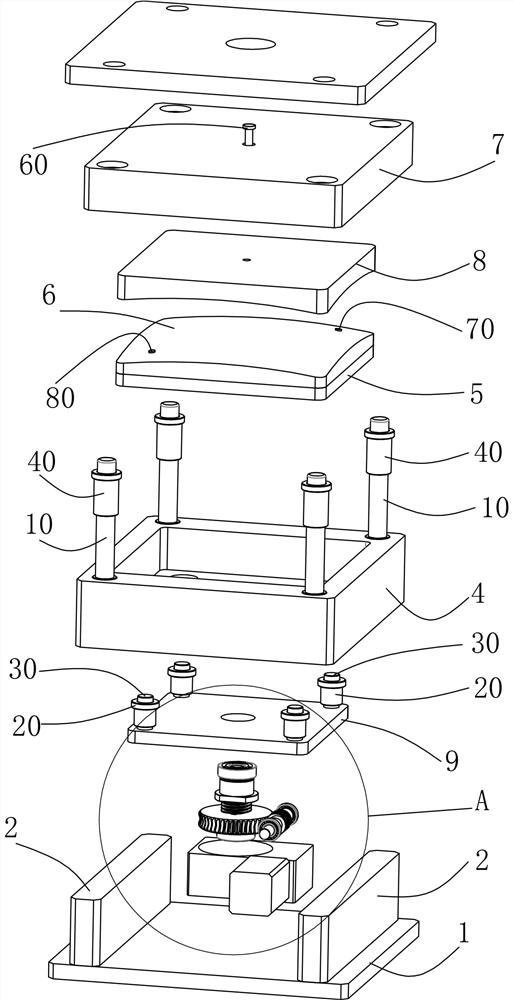

[0027] like Figure 1 to Figure 4 As shown, a double self-locking stroke continuously adjustable high-precision micro-spacing foaming mold described in this embodiment includes a bottom plate 1, two spacers 2 arranged side by side on the bottom plate 1, and an opener with self-locking function. Distance from drive mechanism 3, lower die base 4, sliding plate 5, lower die core 6, upper die base 7 and upper die core 8;

[0028] The distance drive mechanism 3 is arranged on the bottom plate 1 and is located between the two cushion blocks 2, and the output end of the distance drive mechanism 3 is connected with a lifting plate 9;

[0029] The lower die base 4 is fixed on the two spacers 2 and is located above the lifting plate 9, and the lower die base 4 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com