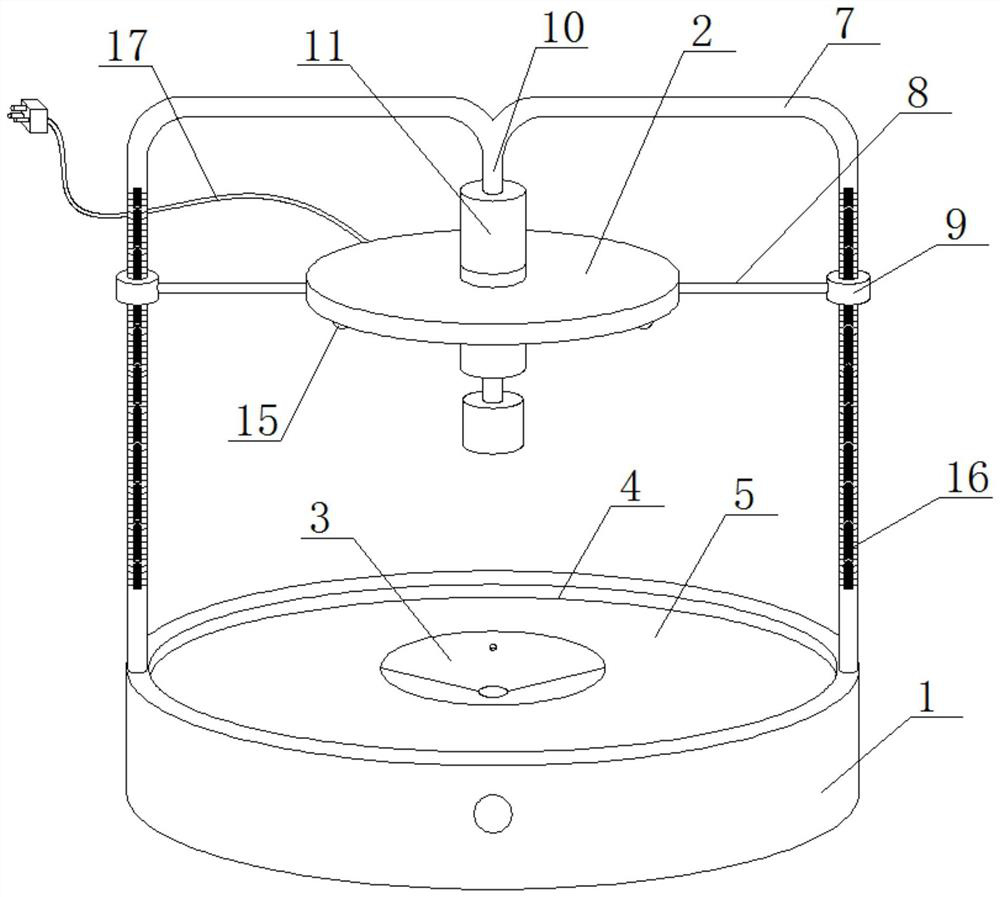

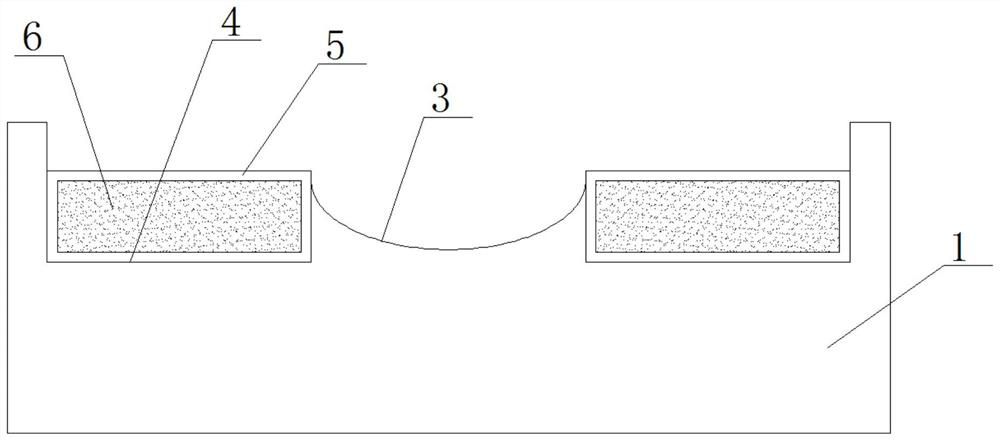

Ultrasonic suspension device

A suspension device and ultrasonic technology, applied in transportation and packaging, conveyors, non-mechanical conveyors, etc., can solve the problems that affect the progress of ultrasonic suspension, cannot adjust the position of the ultrasonic generator, and are not conducive to the improvement of ultrasonic suspension accuracy. Conducive to observation and operation, strong practicability, and the effect of avoiding tool damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0024] As a preferred embodiment of the present invention, one end of the power cord 17 is connected with a plug.

[0025] As a preferred embodiment of the present invention, the power cord 17 is electrically connected to the LED lamp 15 and the ultrasonic generator 2 respectively.

[0026] As a preferred embodiment of the present invention, a switch is installed on the base 1 , and the switch and the LED lamp 15 are connected in series with the power line 17 .

[0027] As a preferred embodiment of the present invention, the inner diameter of the limiting collar 9 is the same as the diameter of the U-shaped installation rod 7 .

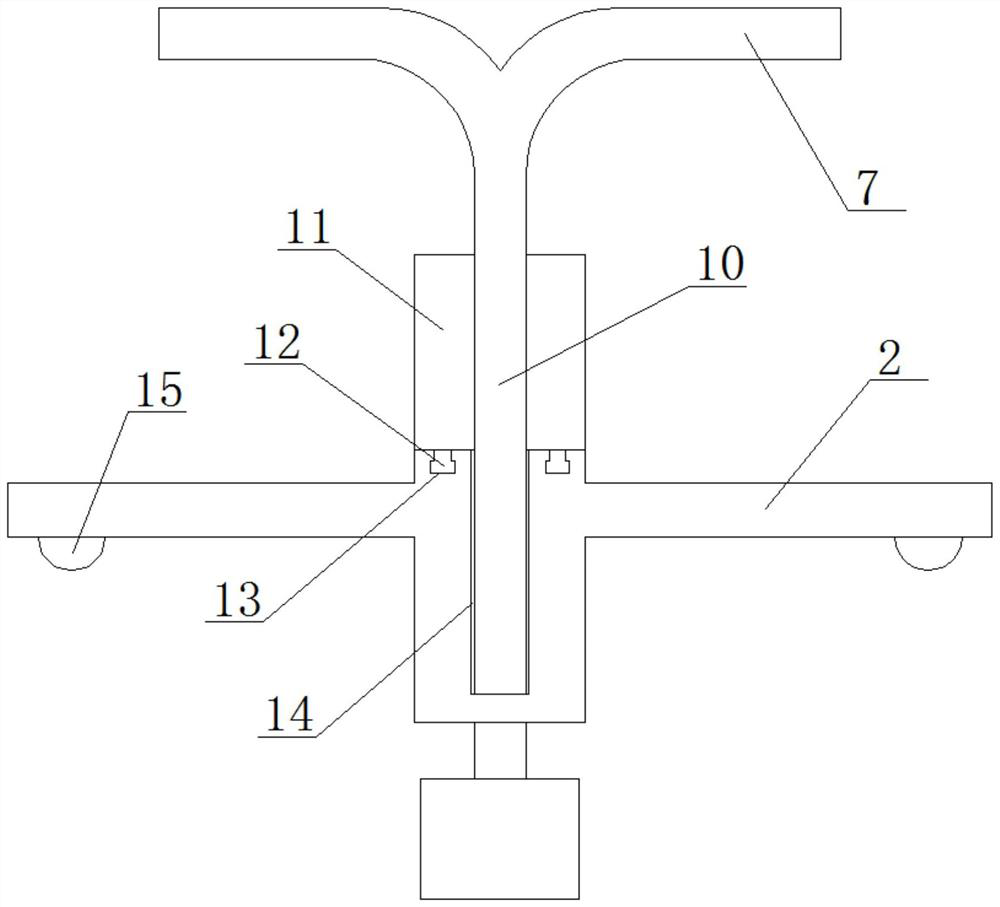

[0028] As a preferred embodiment of the present invention, the bottom of the adjusting coil 11 is fixedly connected with a convex slider 12, and the top of the ultrasonic generator 2 is provided with a convex slider at a position corresponding to the convex slider 12. Groove 13, the convex sliding block 12 is movably installed in the convex sliding g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com