Sliding seat rolling system with multi-stage rolling assembly

A rolling group, multi-stage technology, applied in the direction of linear motion bearings, bearing components, shafts and bearings, can solve the problems of large force on the cage, affecting the service life of the equipment, and the cage is prone to breakage, so as to avoid being damaged Pull off, prolong service life, enhance the effect of flexible function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further explain the technical means and effects adopted by the present invention to achieve the intended invention purpose, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

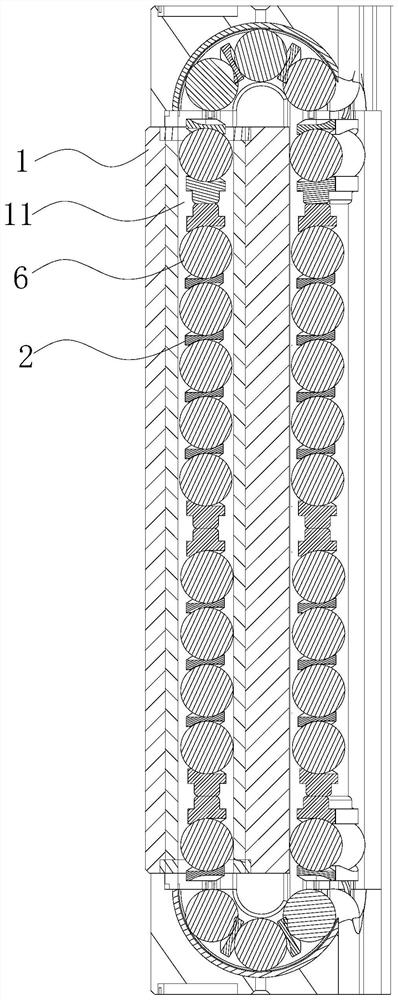

[0033] Such as figure 1 As shown, a sliding seat rolling system with a multi-stage rolling assembly includes a rolling element circulation passage 11 arranged in the sliding seat 1, several rolling elements 6 rollingly connected in the rolling element circulation passage 11 and six retainers 2.

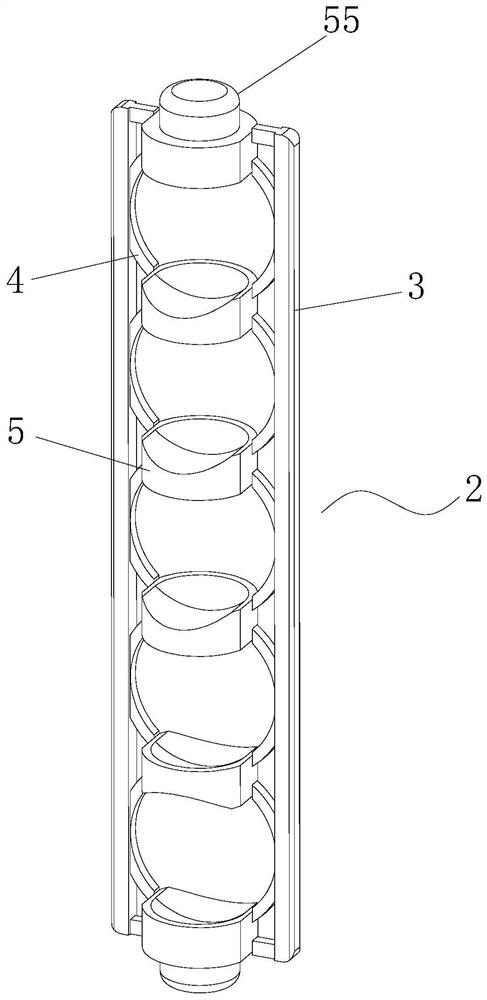

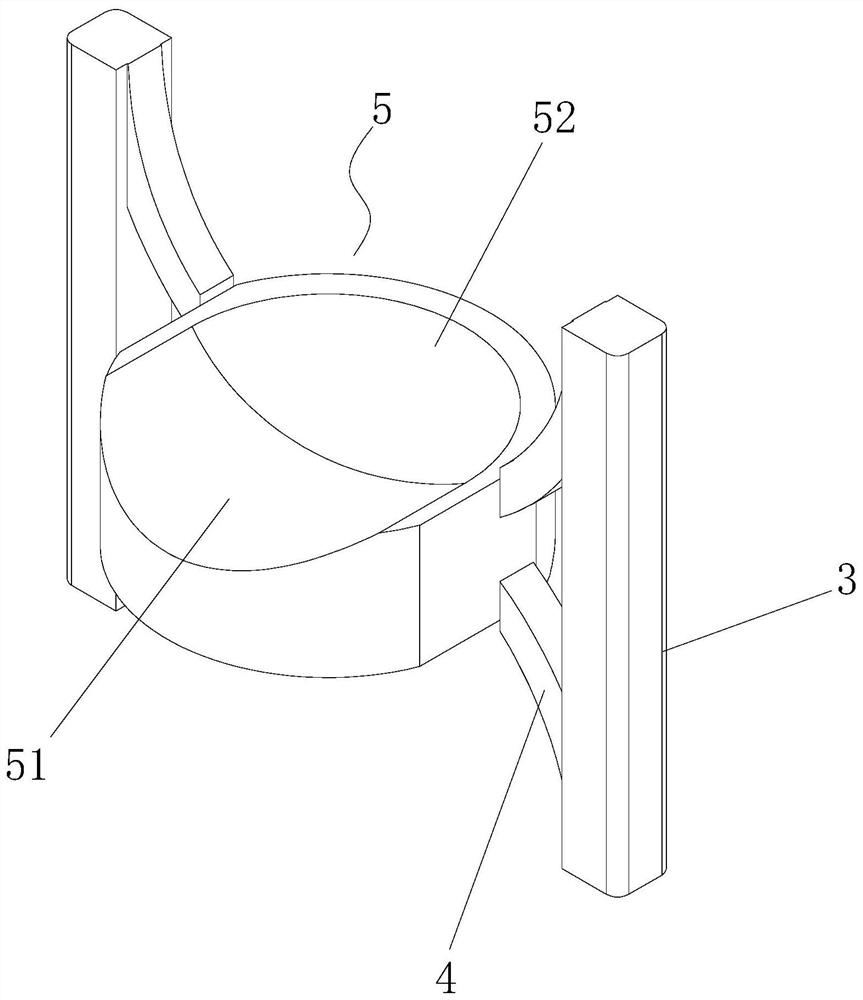

[0034] Such as Figure 2-3 As shown, the retainer includes a tensile strap 3 , a connecting strap 4 and a spacer 5 .

[0035] Wherein, the tensile belt 3, the connecting belt 4 and the spacer 5 are prepared by integral injection molding.

[0036] The quantity of tension band 3 is two and arranged in parallel, the cross section of tension band 3 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com