All-glass fiber Bragg grating tilt angle sensor

An inclination sensor and fiber grating technology, which is applied in the field of sensors, can solve the problems of low sensitivity of inclination sensors, prolong the life of sensors, and long measurement time, so as to avoid sensor cracks, eliminate cross-sensitivity of temperature and strain, and have good homogeneity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

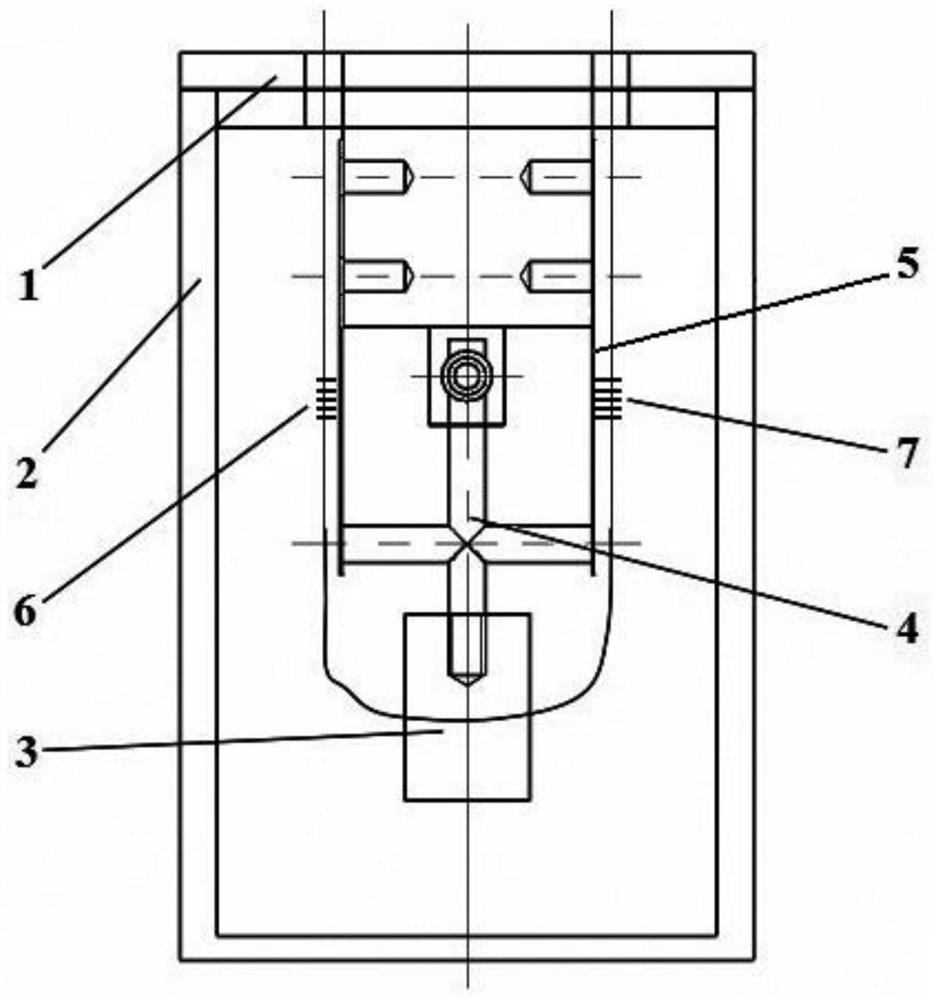

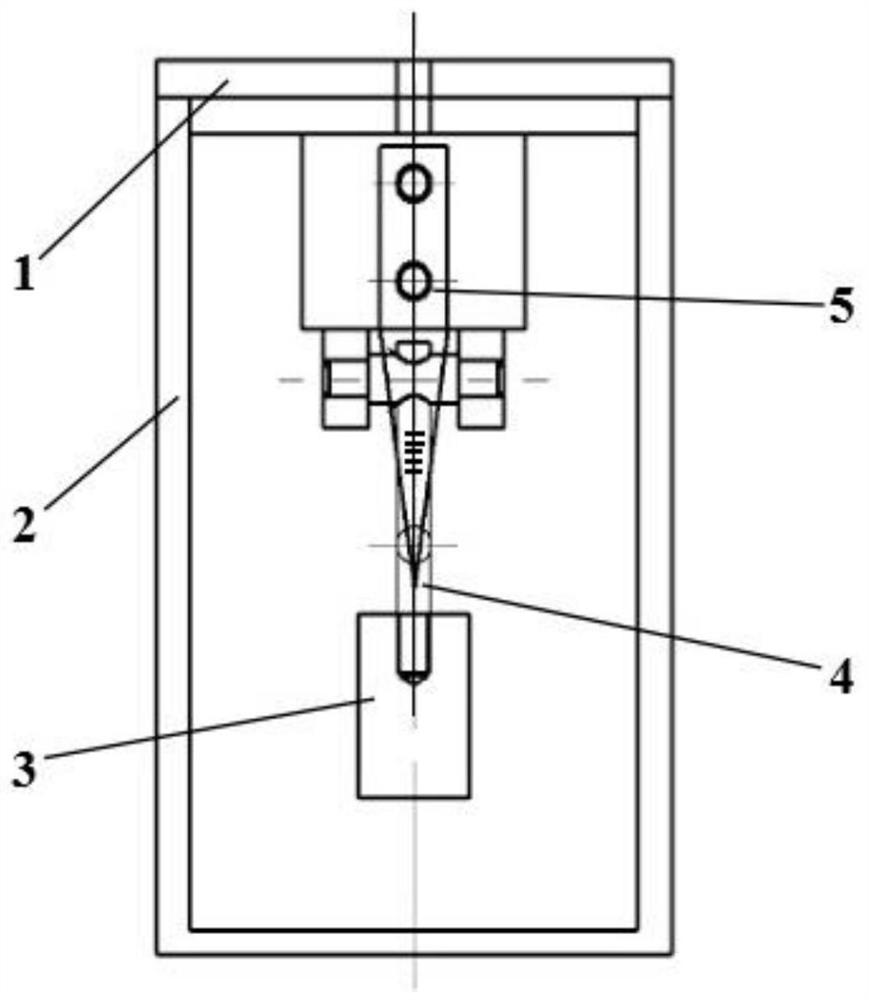

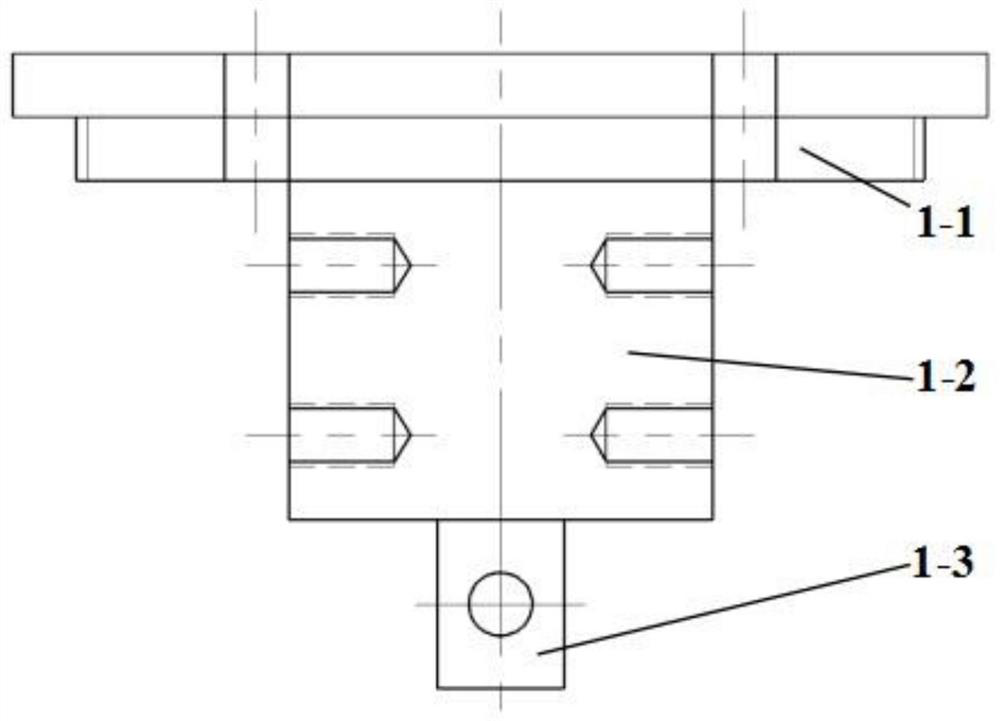

[0041] A fiber grating inclination sensor made of all glass, comprising: a glass cover 1, a glass cylinder 2, a first fiber grating 6, an equal-strength tempered glass beam 5, a second fiber grating 7, a cross glass rod 4, and a glass block 3; The inner wall of the upper part of the glass cylinder 2 is provided with an internal thread, which is connected with the external thread of the cylindrical surface of the glass cover 1 to form an airtight space; the glass cover 1 is composed of a cylindrical surface 1-1, a cube 1 -2 and cuboid block 1-3 are composed of three parts. The two sides of the cube block 1-2 are symmetrically provided with 4 threaded holes, and there are 2 optical fiber access holes in the vertical direction at the center of the two sides. The cuboid block 1- 3. There are 2 through holes in the central position; the equal-strength tempered glass beam 5 is fixed on both sides of the cube block 1-2 by screw connection; the cross glass rod 4 is fixed on the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com