Bend pipe split mold and bend pipe manufacturing method

A manufacturing method and pipe bending technology, which are applied in the field of pipe bending processing, can solve problems such as poor quality of the pipe bending, and achieve the effects of improving uneven thickness, improving control accuracy and saving manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

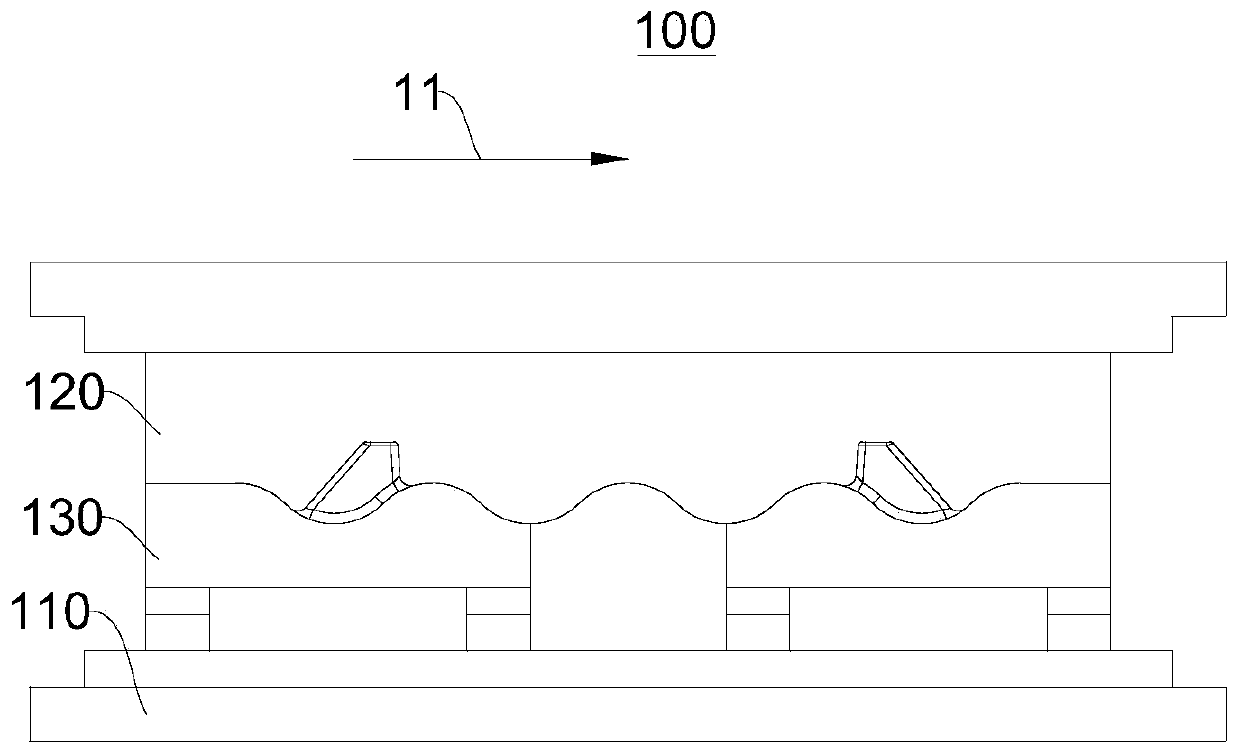

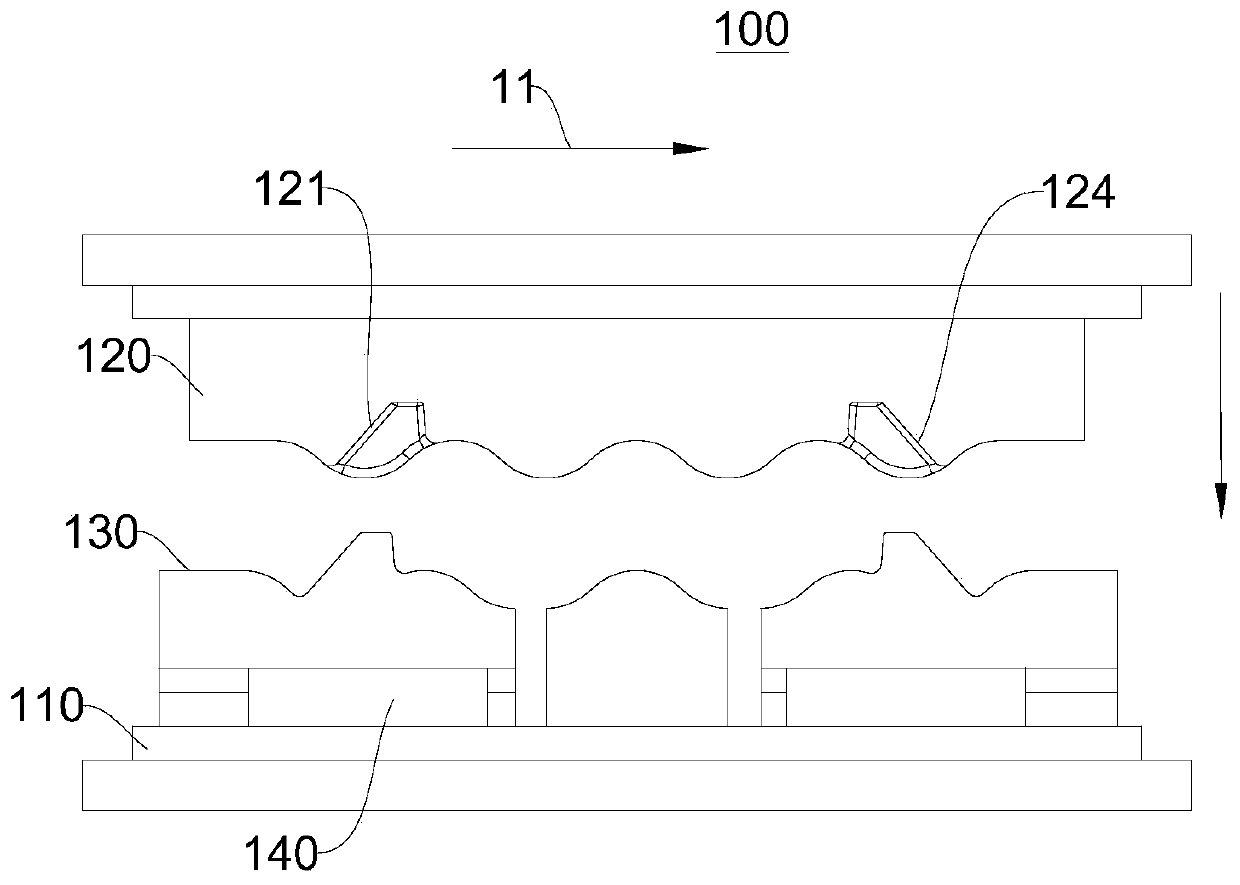

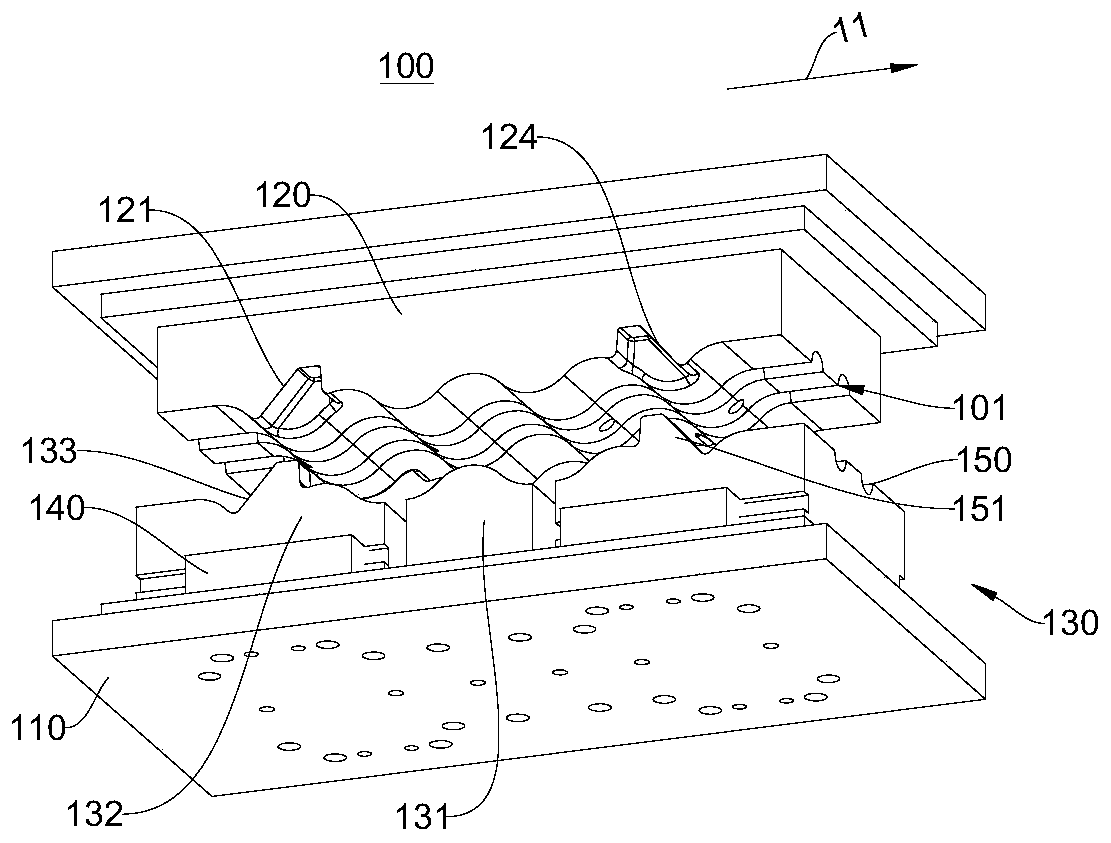

[0052] figure 1 A schematic structural view of the first state of the elbow split mold 100 provided by the embodiment of the present application is shown, figure 2 It shows a schematic structural view of the second state of the elbow split mold 100 provided by the embodiment of the present application, image 3 It shows a structural schematic diagram of another angle of view of the second state of the elbow split mold 100 provided by the embodiment of the present application, please refer to Figure 1-Figure 3 , this embodiment provides a bent pipe split mold 100, which is mainly used for pressing straight pipes into bent pipes. Elbows can be used to make elbows.

[0053] The parting surface of the elbow split mold 100 is a curved surface. The "curved surface" refers to a surface that is different from a plane. The shape of the curved surface can be set according to the shape of the target elbow. This application does not limit the specific shape of the curved surface .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com