Patents

Literature

31results about How to "Avoid problems such as cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

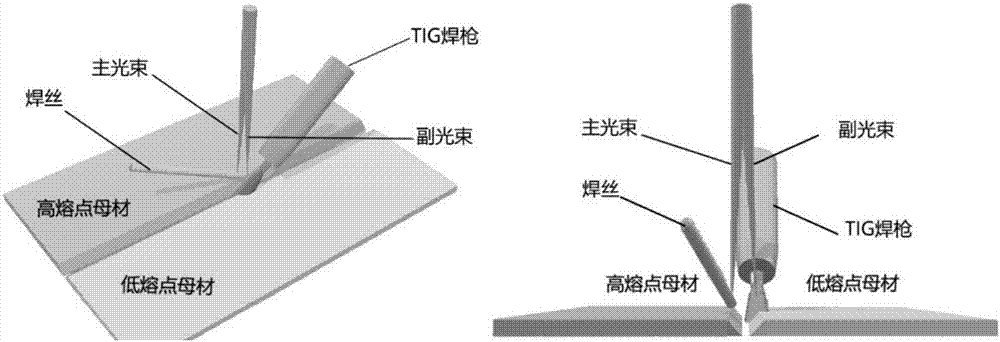

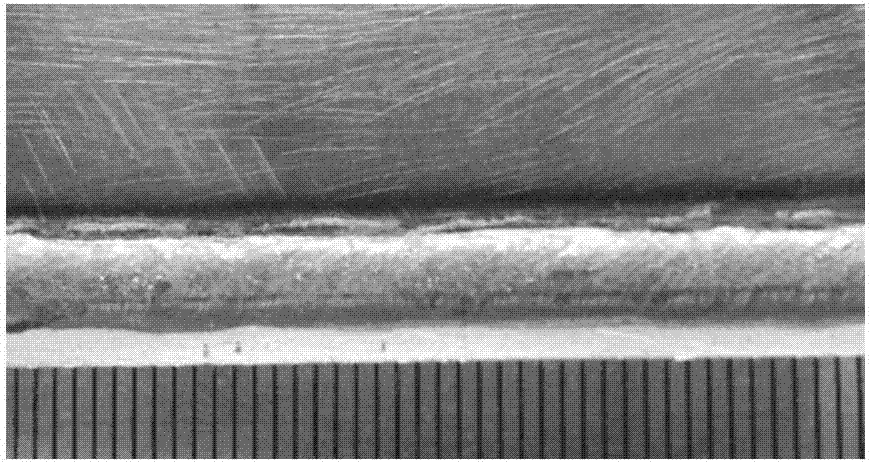

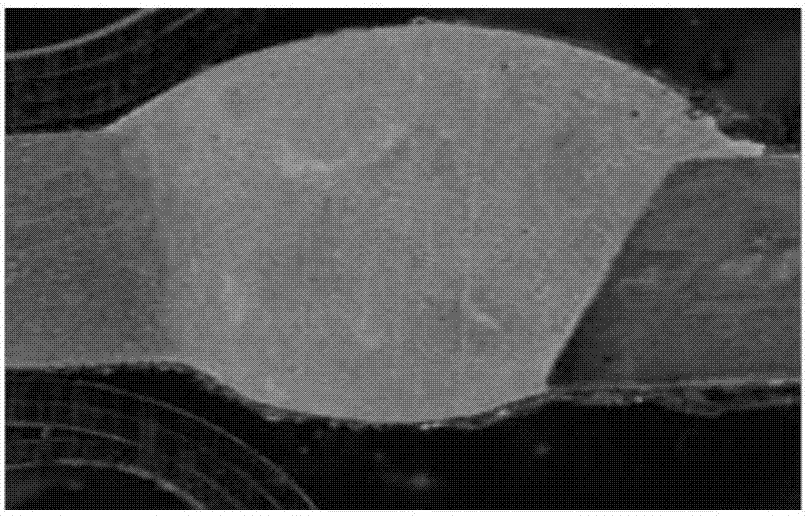

Method adopting double-beam laser and TIG composite filler wire fusing-brazing for dissimilar materials

ActiveCN107999916AAvoid meltingAvoid problems such as cracksSoldering apparatusArc welding apparatusMicrostructureElectric arc

The invention relates to a method adopting double-beam laser and TIG composite filler wire fusing-brazing for dissimilar materials, and relates to the field of material processing engineering. According to the method, the problems existing in the laser-arc composite welding process of the dissimilar materials are solved. Lasers and TIG electric arcs are applied to dissimilar material welding in acomposite mode, the two beams of lasers with different energies are arranged in parallel, and the two light beams act on grooves of mother materials on two sides respectively. According to the methodfor fusing-brazing, distribution of a welding temperature field can be controlled, the welding stability and the heat efficiency are improved, the adaptability to a welding joint is improved, the microstructure of the welding joint is improved, and the welding defect is reduced.

Owner:HARBIN INST OF TECH

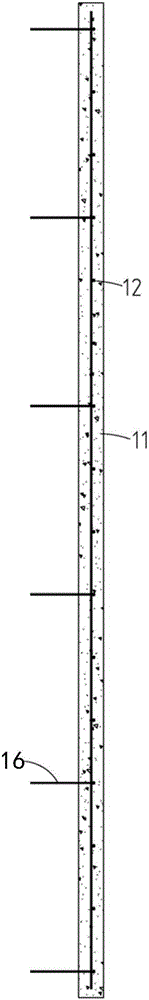

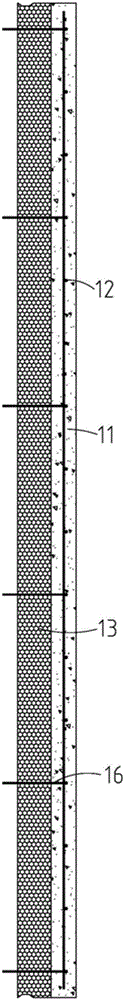

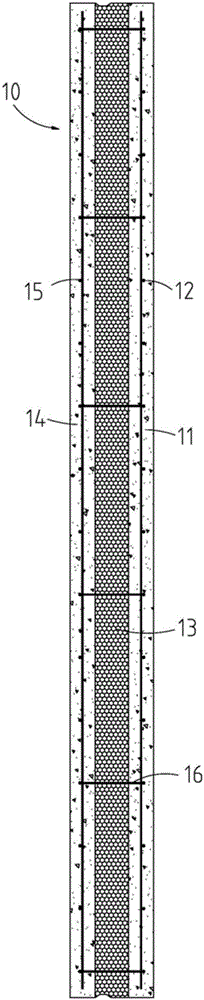

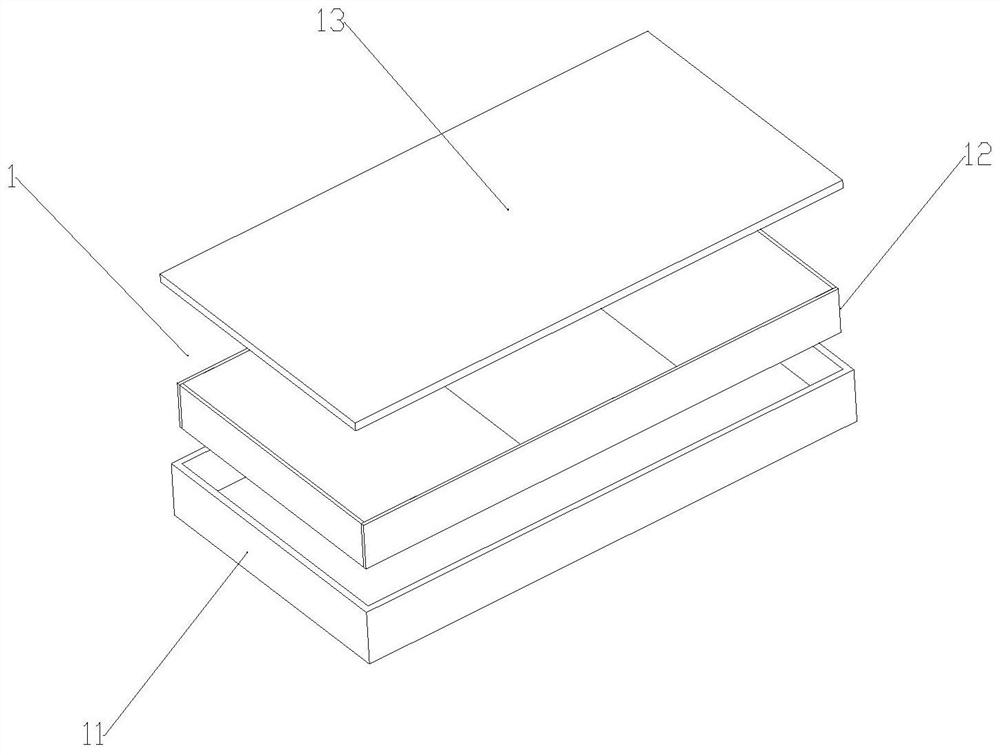

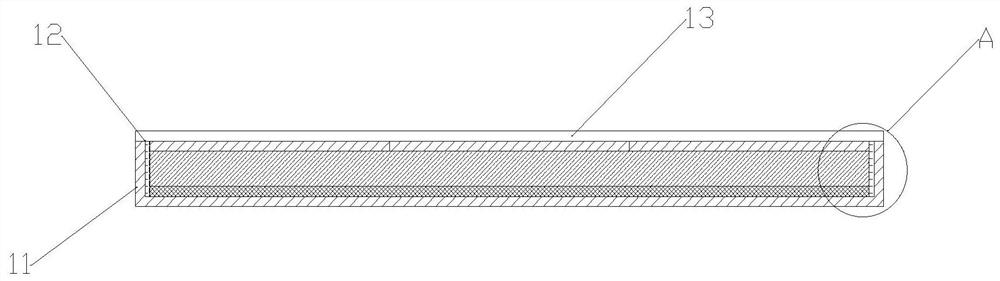

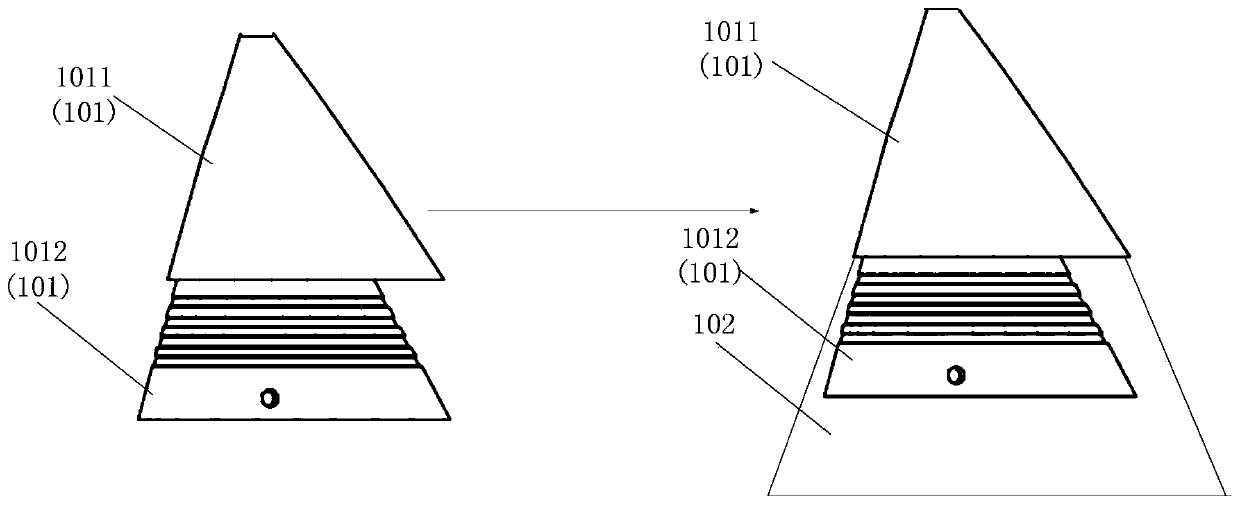

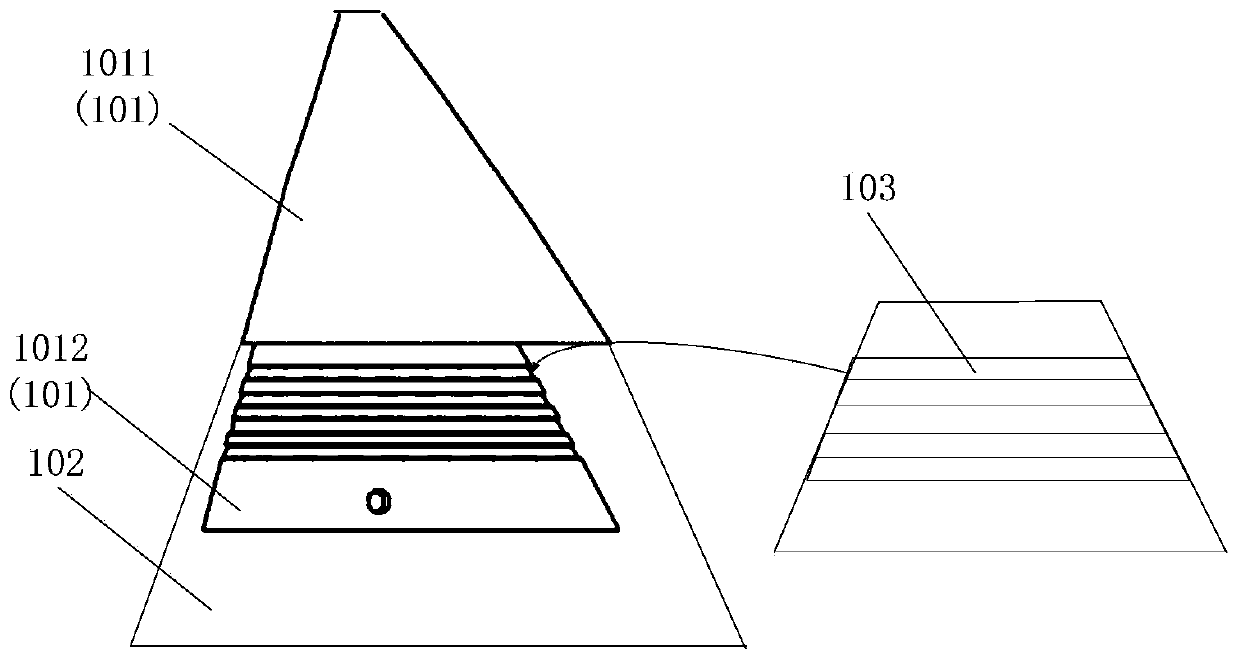

Externally-mounted prefabricated sandwich type thermal-insulation concrete wallboard and assembling system and construction method thereof

ActiveCN106760158AImprove structural strengthIncrease stiffnessPassive housesBuilding componentsFloor slabThermal insulation

The invention provides an externally-mounted prefabricated sandwich type thermal-insulation concrete wallboard and an assembling system and construction method thereof. The technical problem that a connecting structure between vane boards on the two sides of an existing thermal-insulation wallboard is insufficient in strength is solved by enabling steel bar truss web bars in a continuously-bent status to be connected to longitudinal reinforcing bars on an inner vane board and an outer vane board of the thermal-insulation wallboard. In addition, the externally-mounted wallboard is in assembling connection with a steel beam and a floorslab through a pre-buried bolt technical means or a split bolt technical means. Meanwhile, the self-characteristics of a steel structure are considered, and the assembly structure strength between the wallboard and the steel beam as well as between the wallboard and the floorslab is guaranteed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

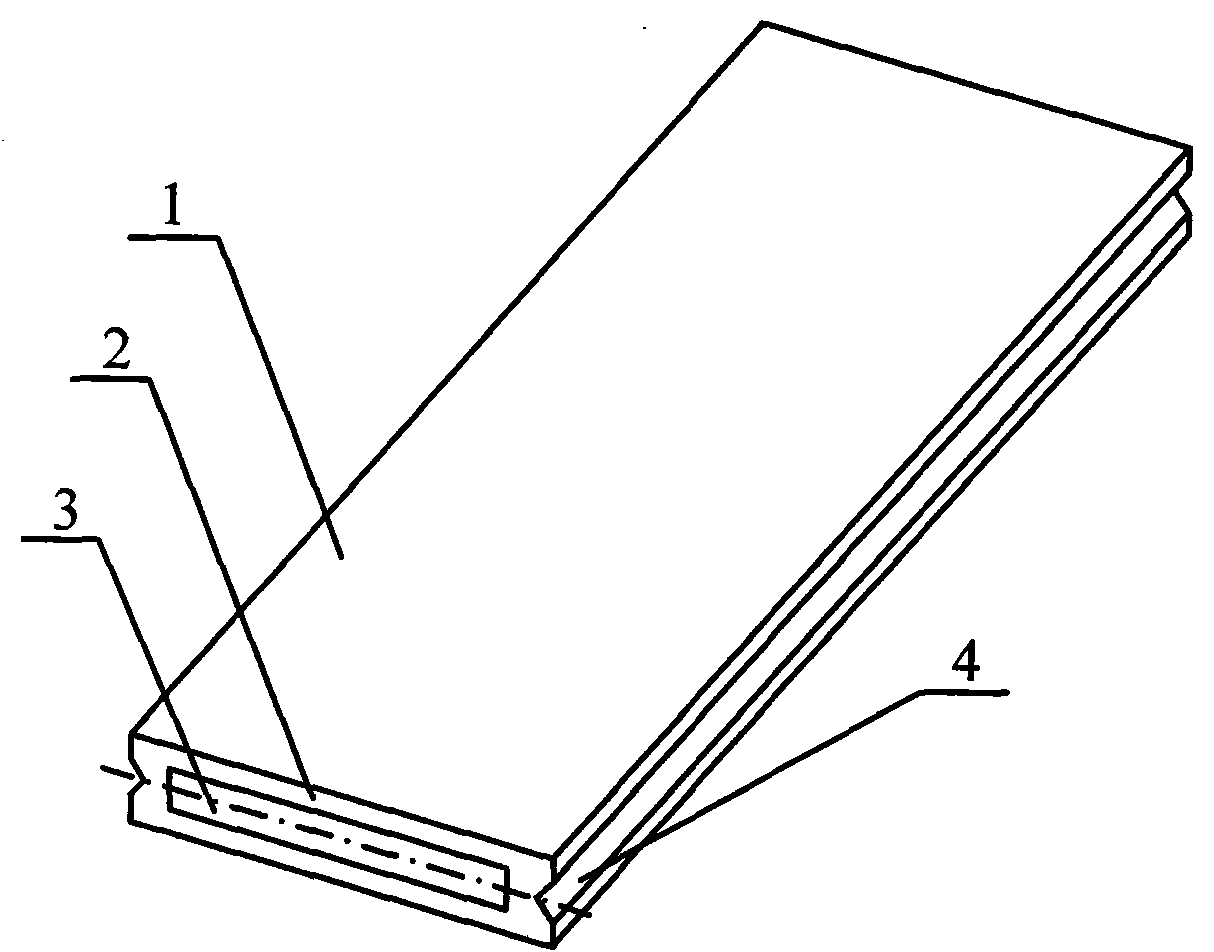

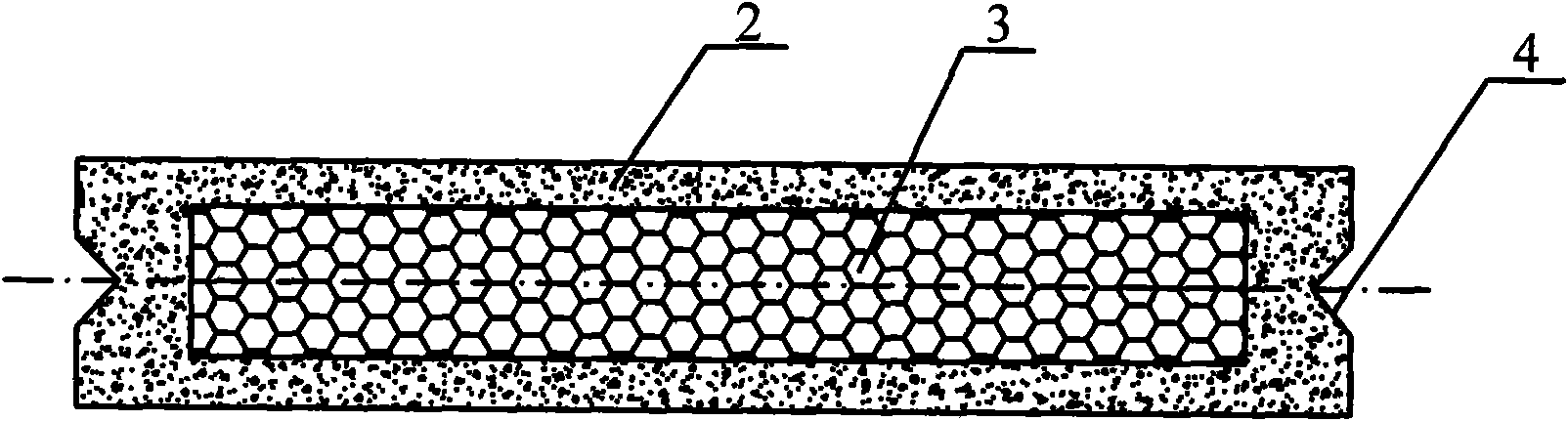

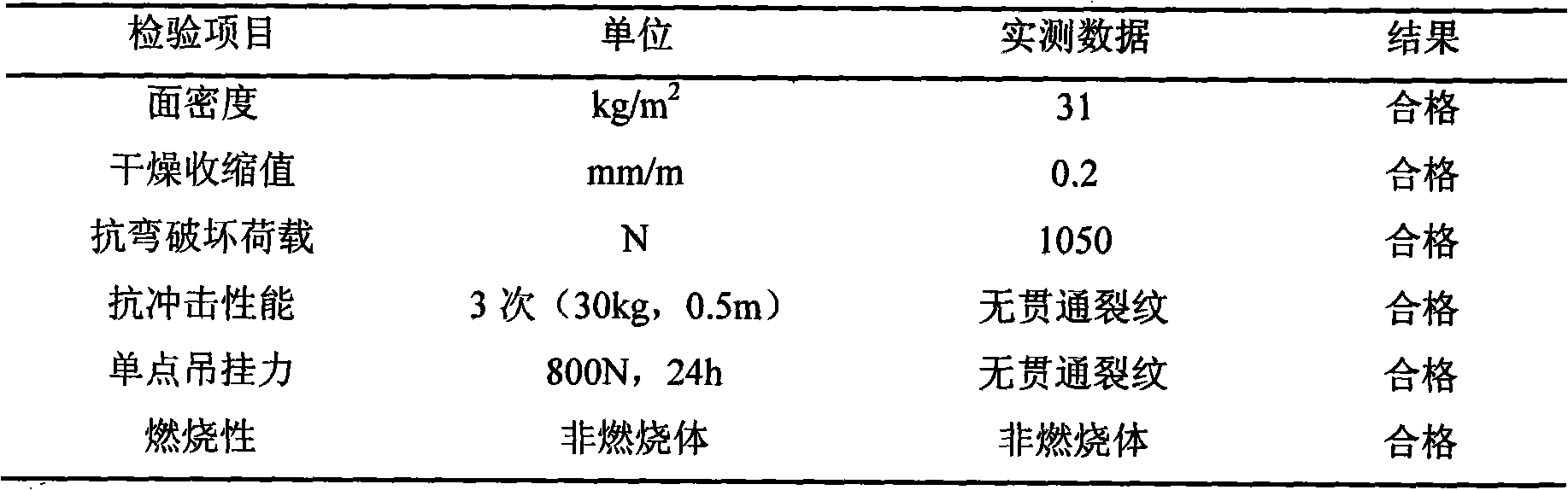

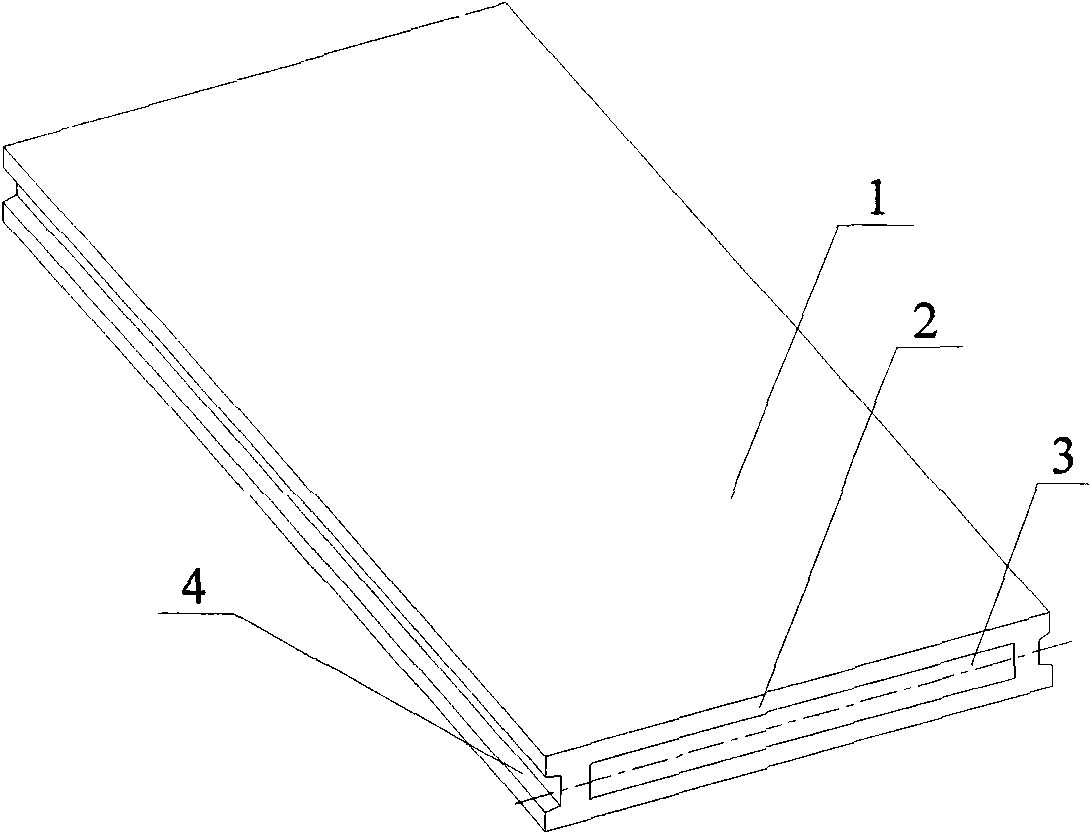

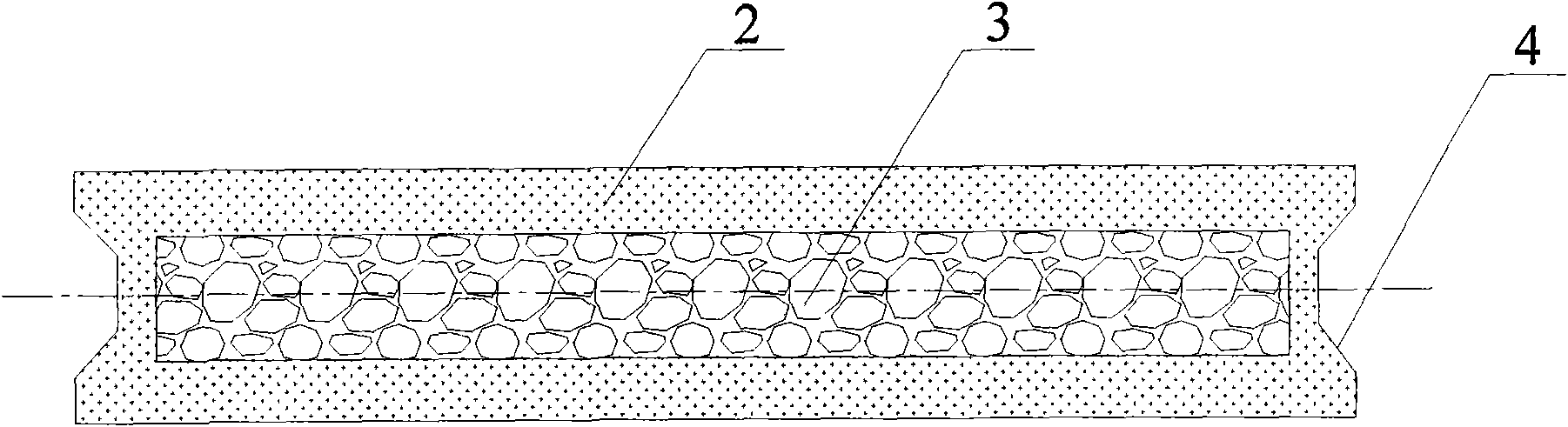

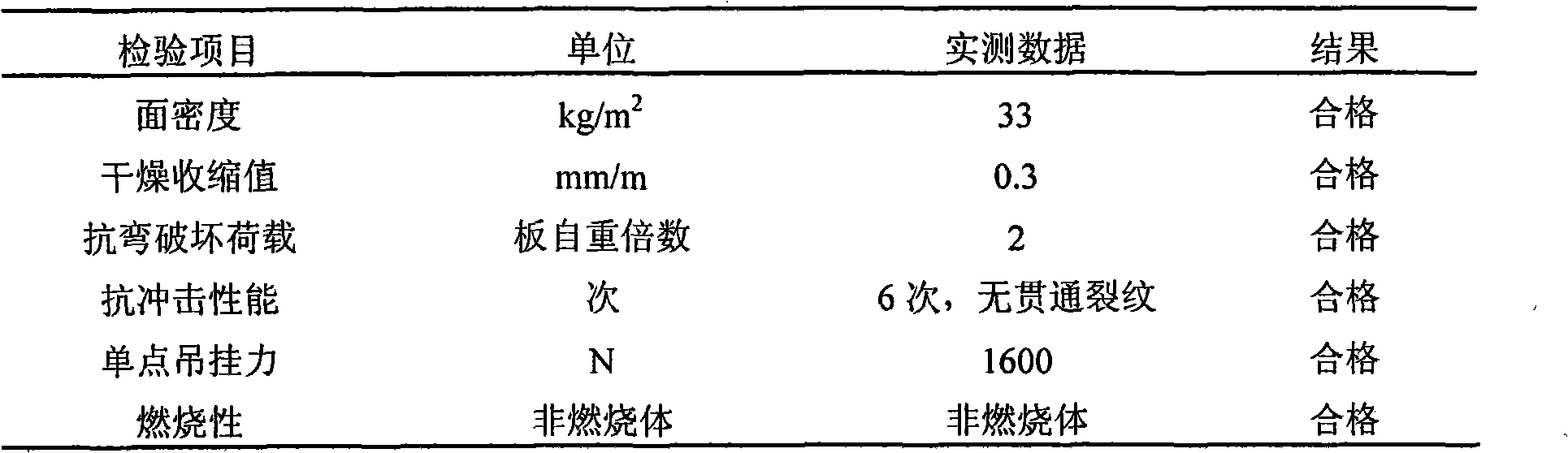

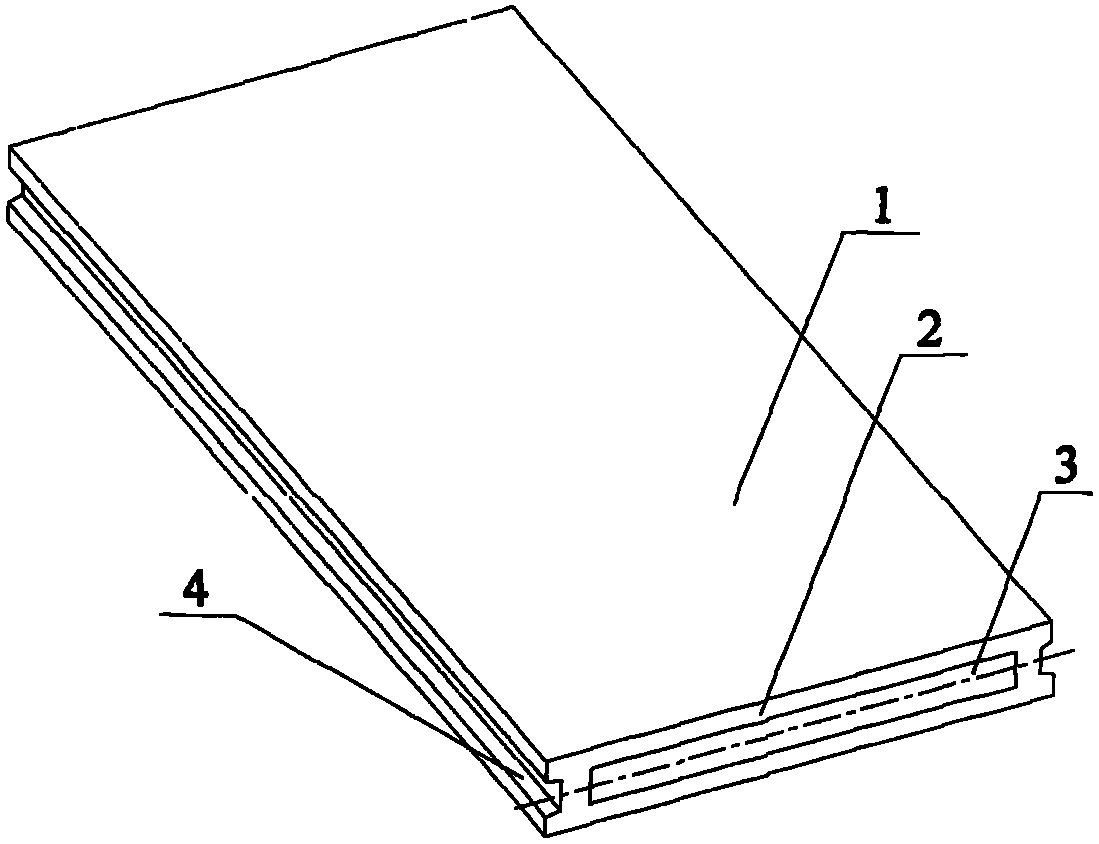

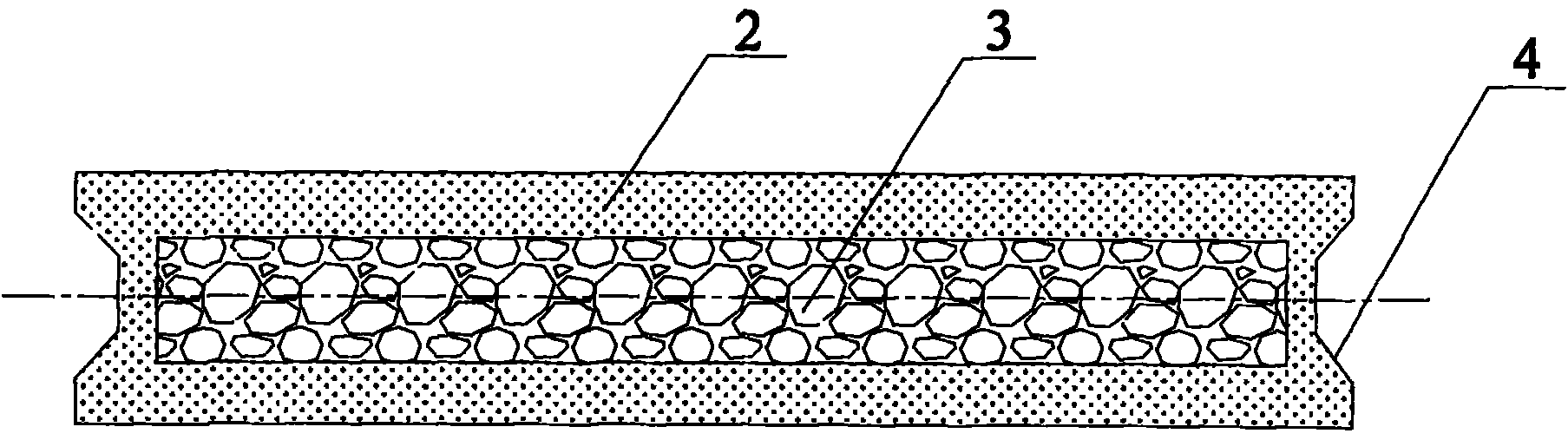

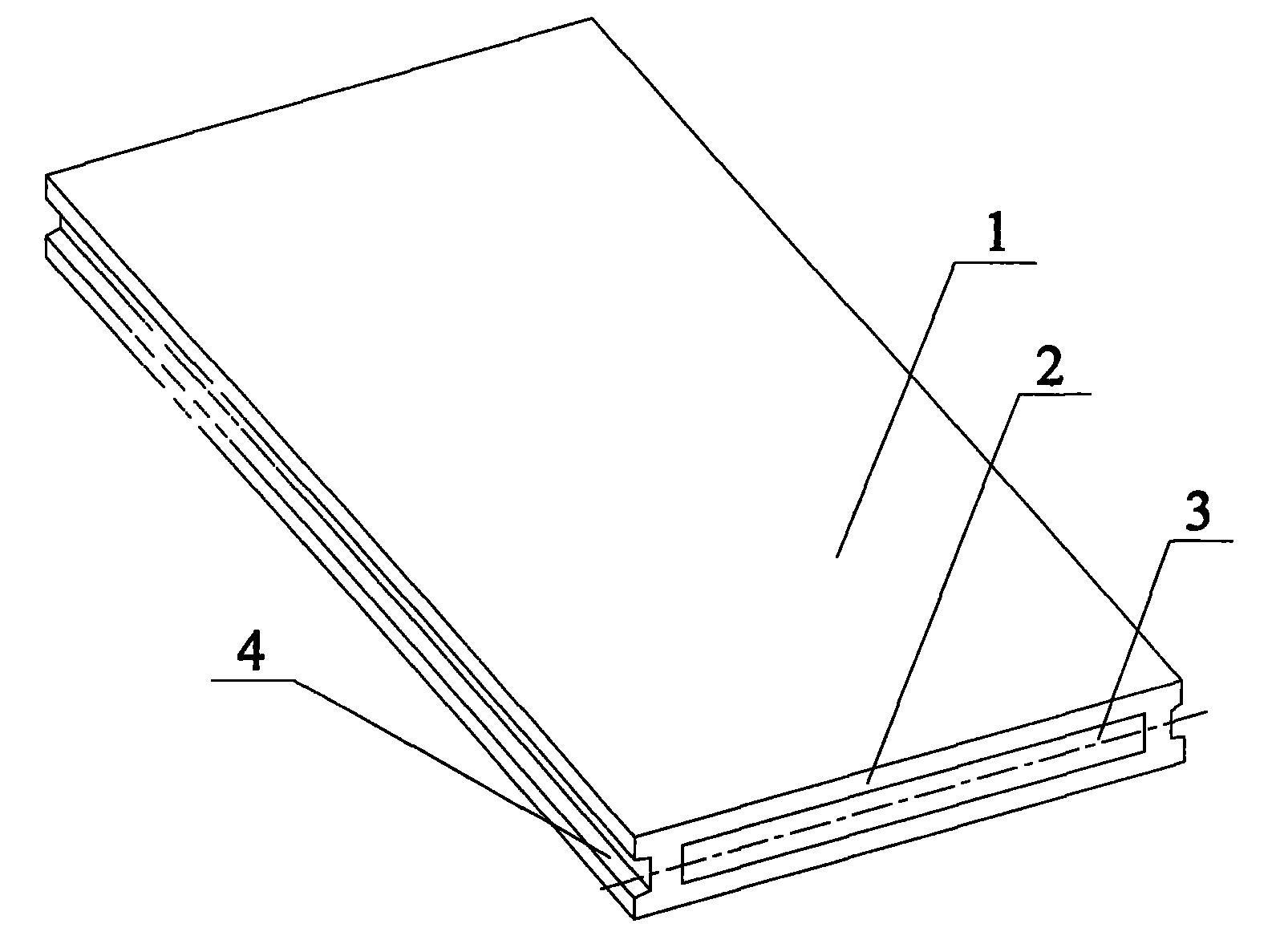

Fluorgypsum light-weight laminboard

InactiveCN101899885AAvoid problems such as cracksEasy for construction and installationBuilding componentsThermal insulationPolystyrene

The invention belongs to the technical field of gypsum building materials, and relates to a light-weight laminboard, which is manufactured by compositing a surface course material mainly prepared from ground and calcined fluorgypsum on a polystyrene plastic foam board core material, and of which both sides are provided with grooves. In the laminboard, the surface course material coated outside a polystyrene plastic foam board is prepared from the following raw materials in part by weight: 100 parts of fluorgypsum powder, 2 to 6 parts of sulphoaluminate cement, 1 to 3 parts of sodium sulfate and 0.5 to 1.5 parts of glass fibers, wherein the ratio of water to the raw materials is 0.50-1.0. The product performance reaches national quality standards; and the fluorgypsum light-weight laminboard has the functions of light weight, high strength, heat preservation, heat insulation, sound insulation and the like, and is a walling material which can be applied to buildings with frame structures.

Owner:UNIV OF JINAN

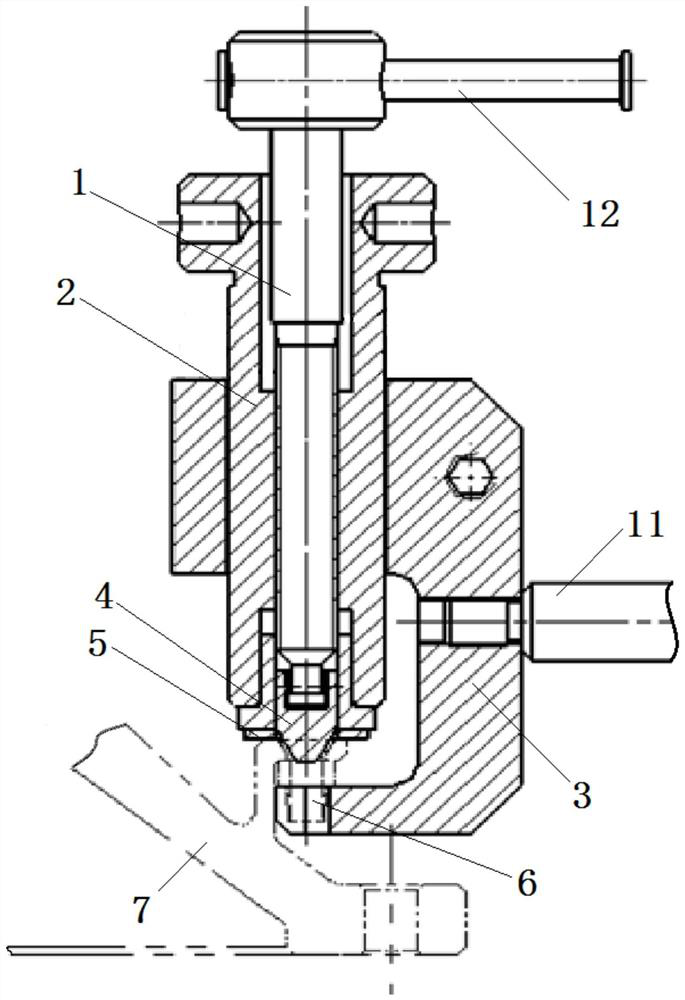

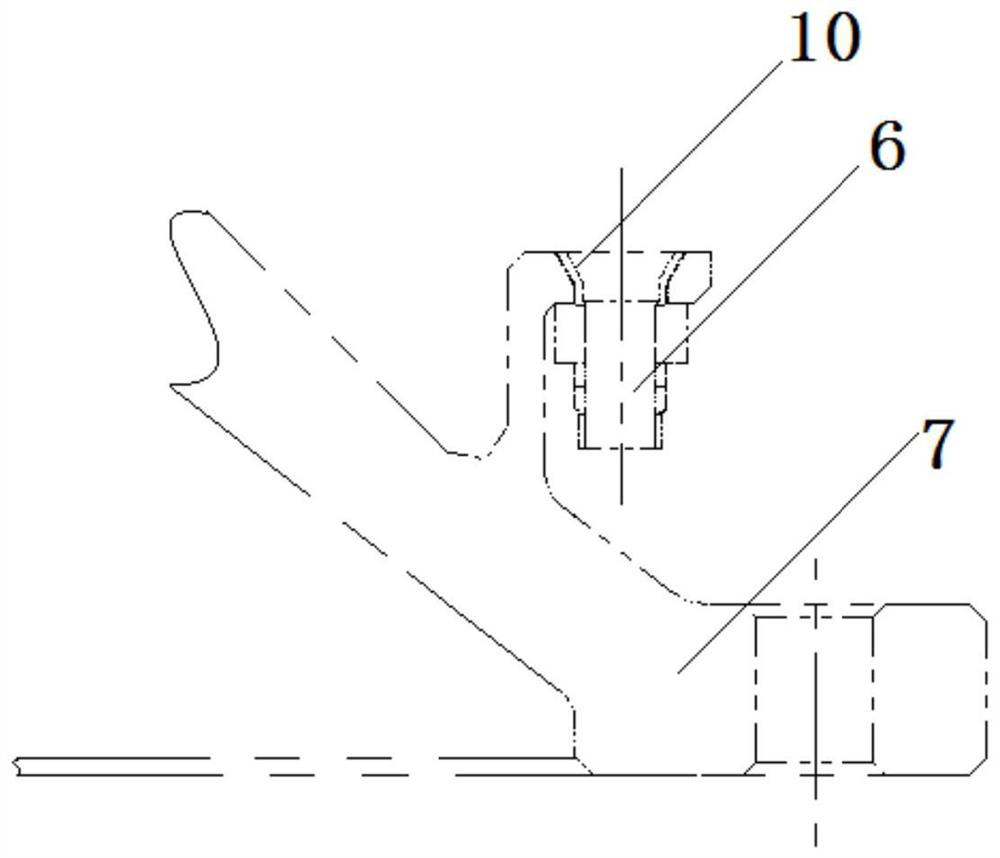

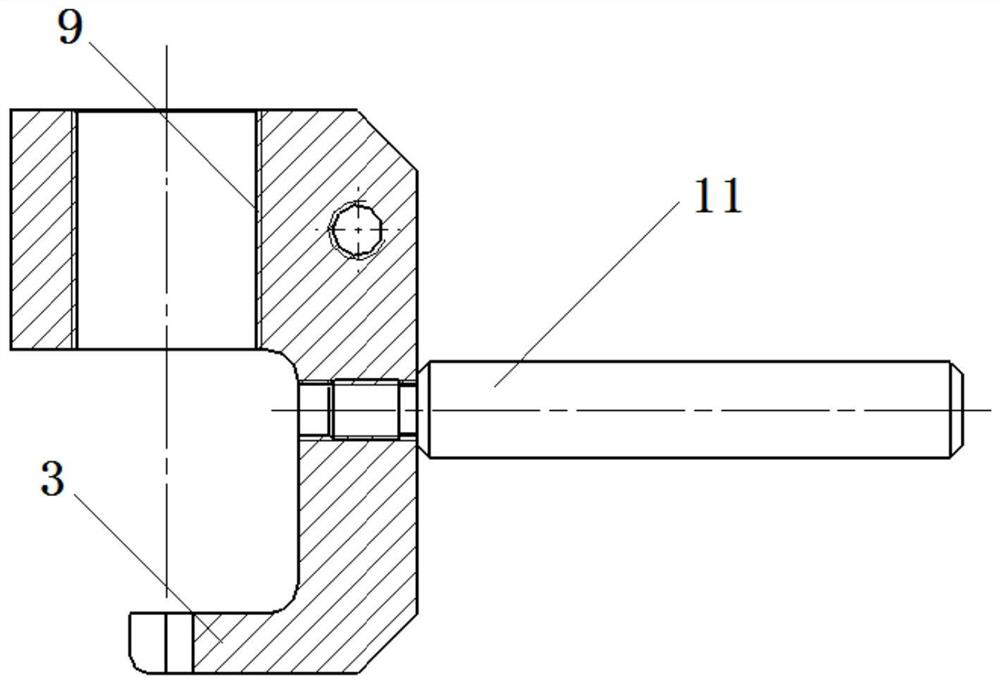

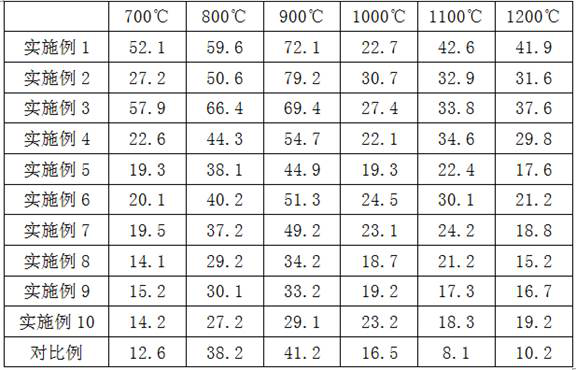

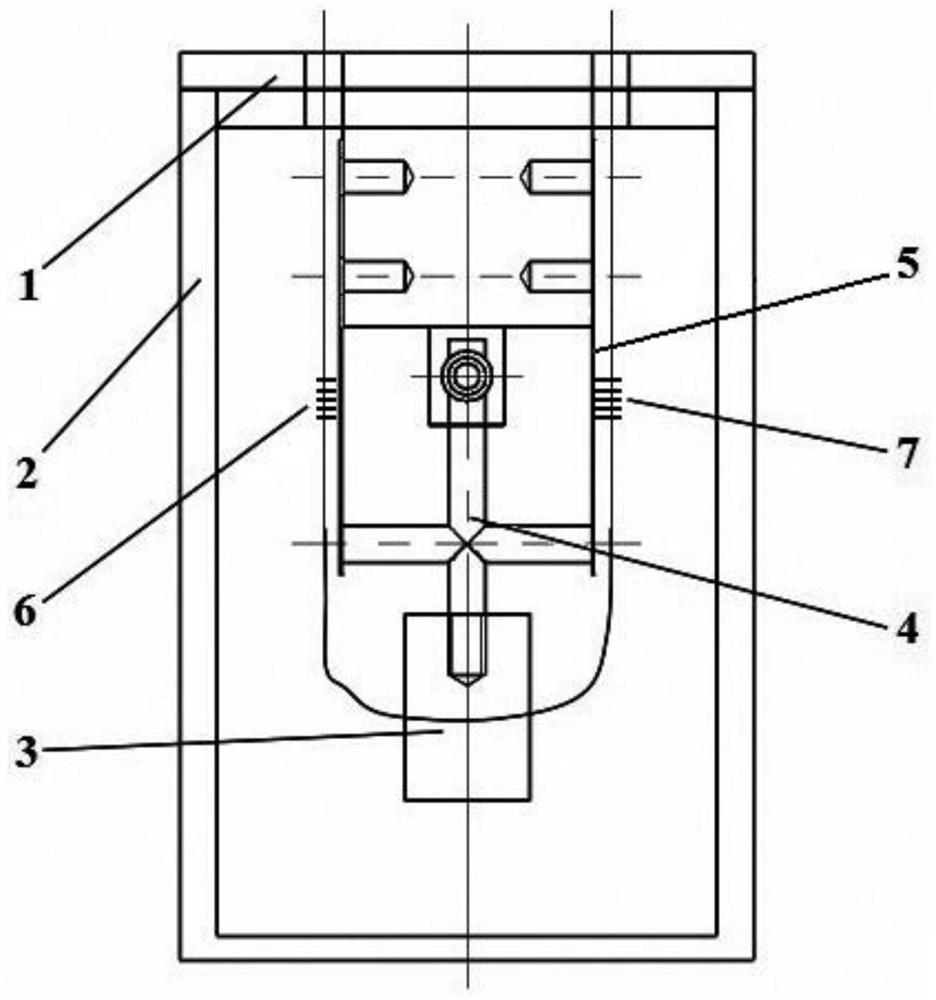

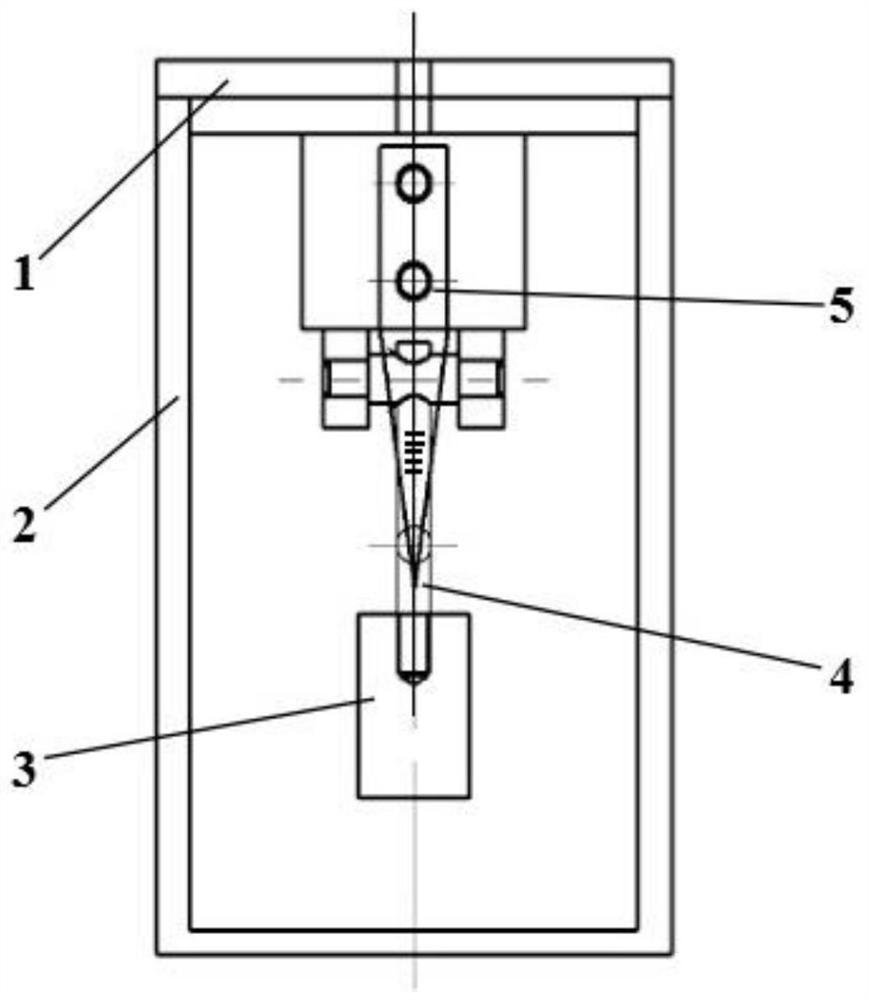

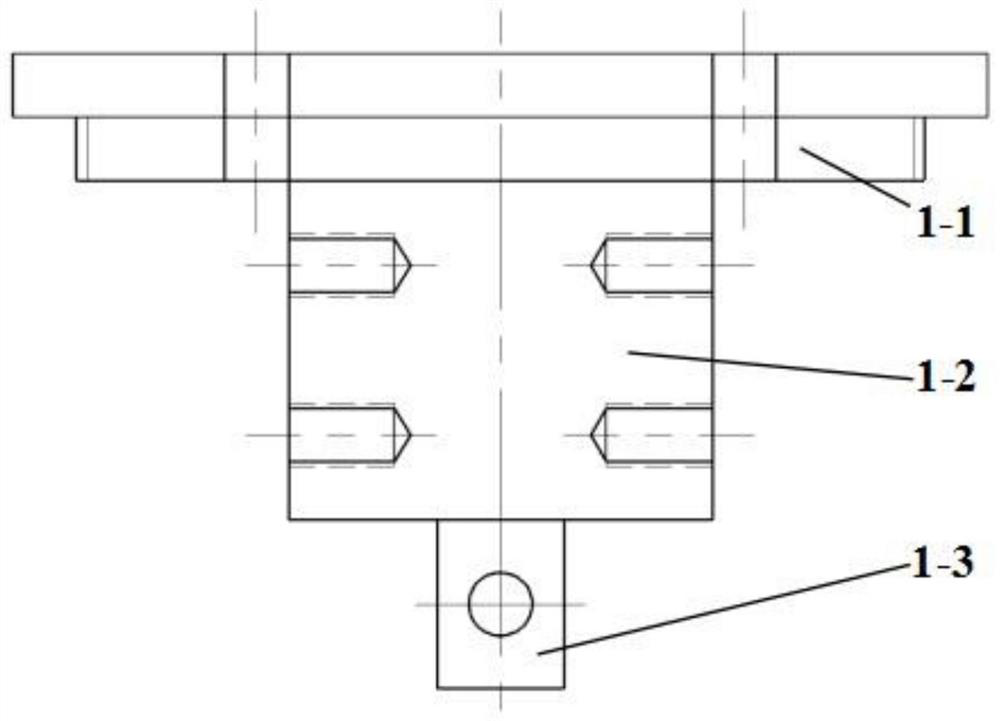

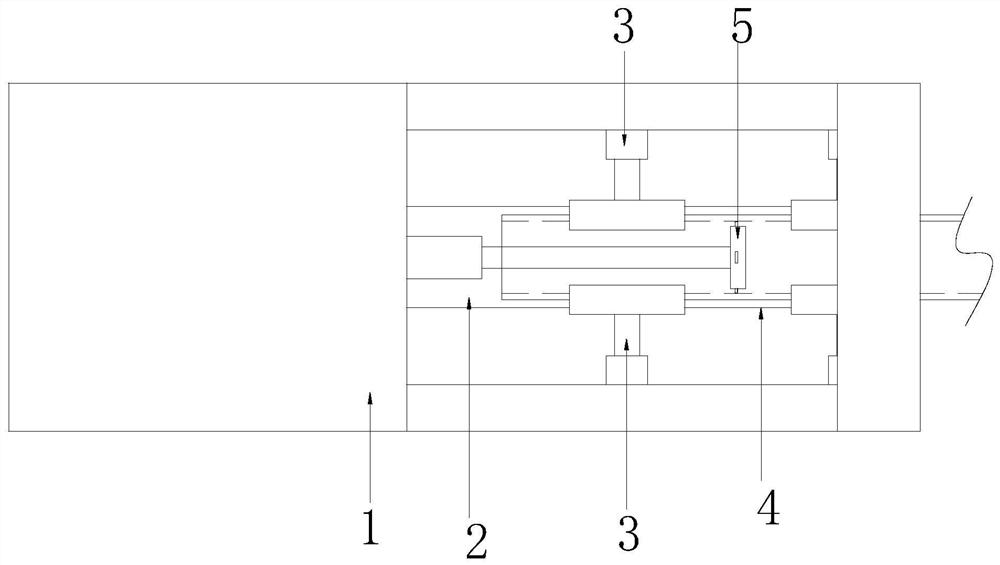

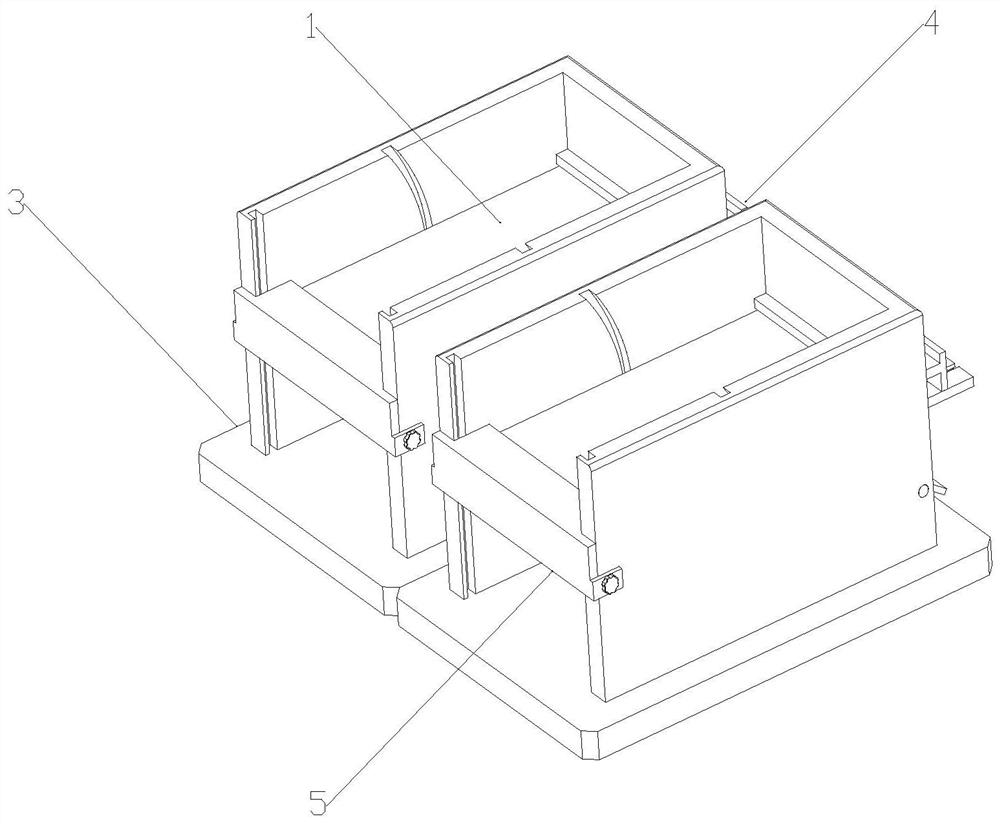

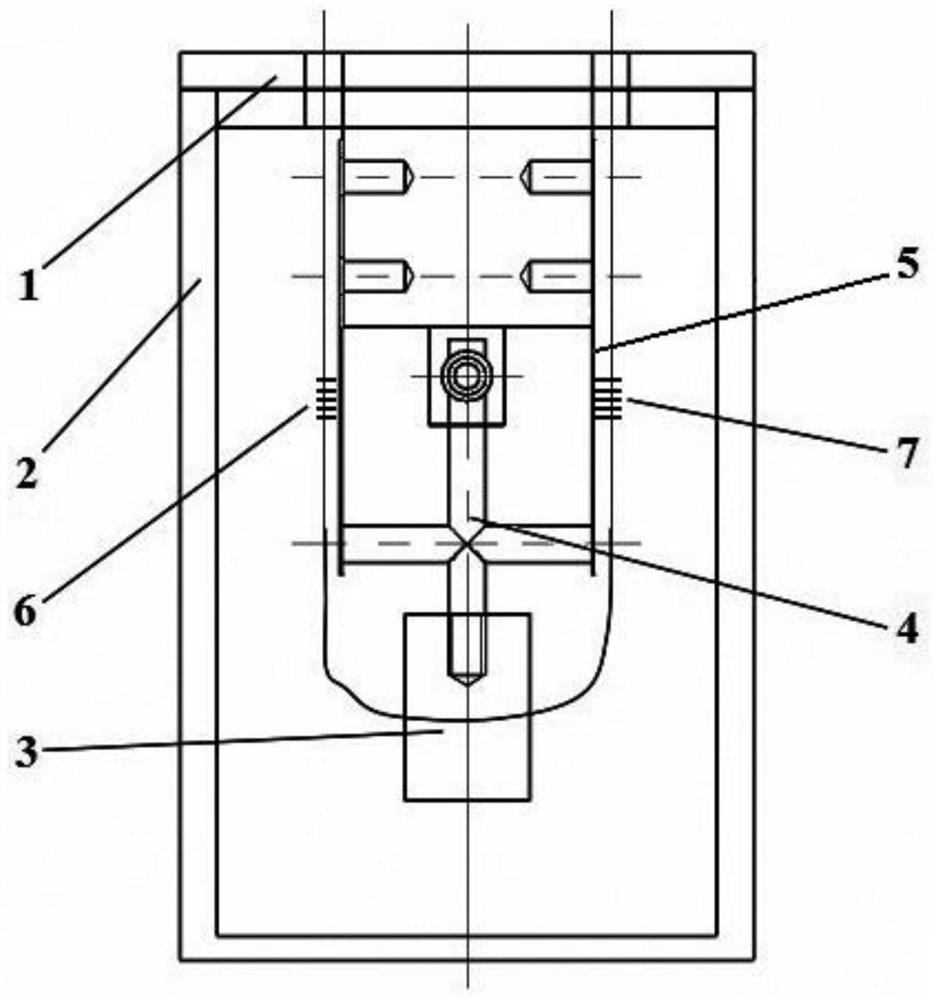

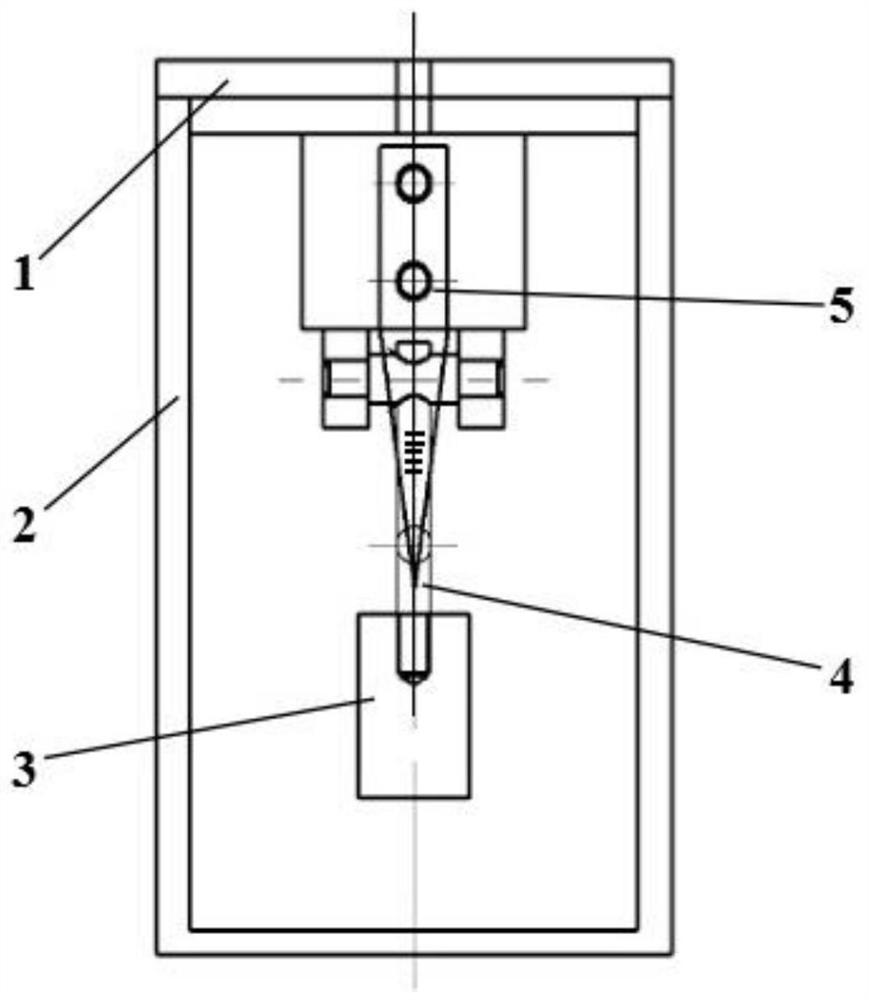

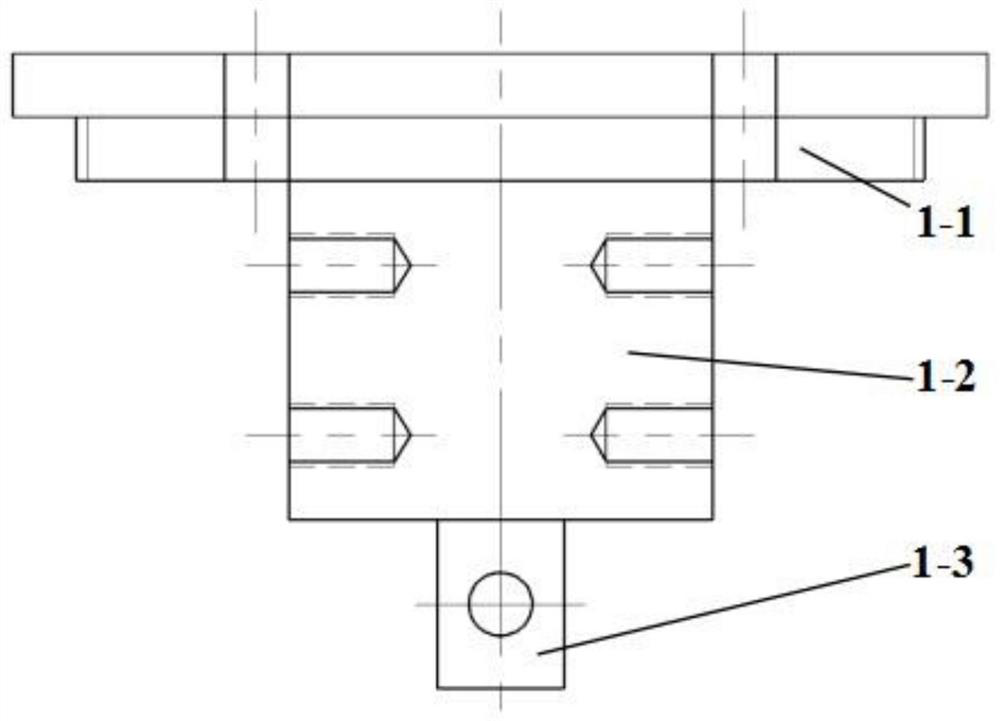

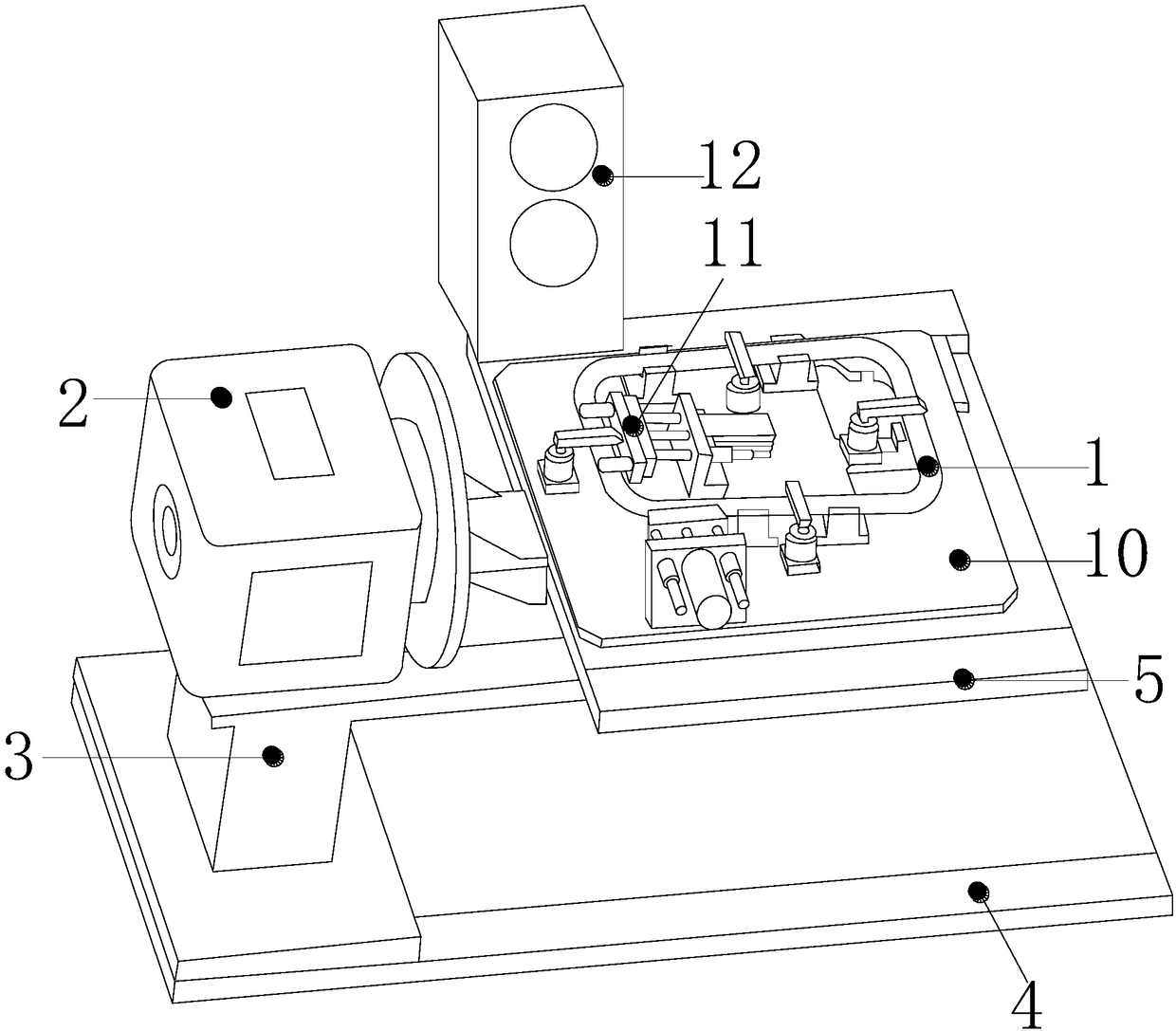

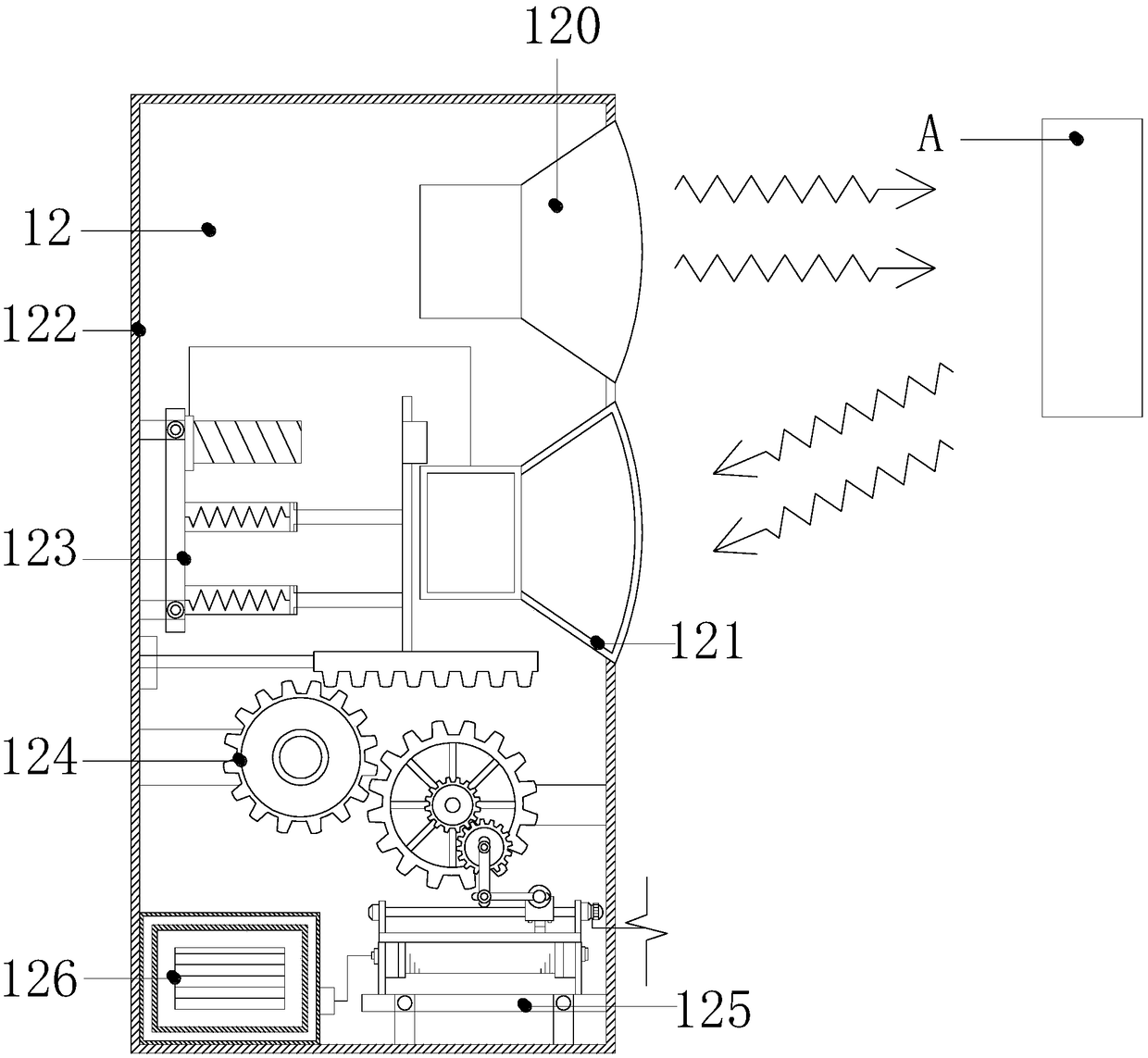

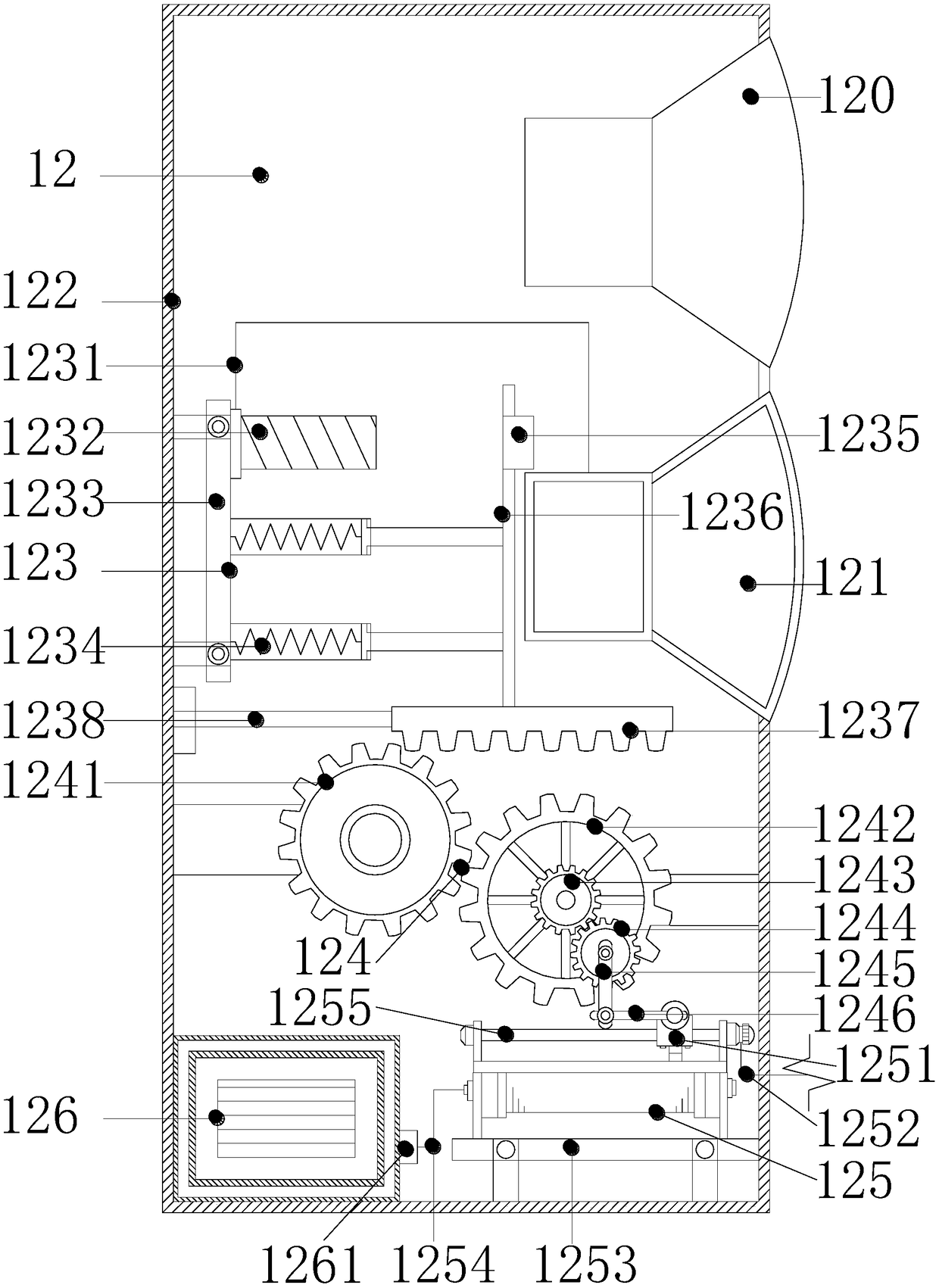

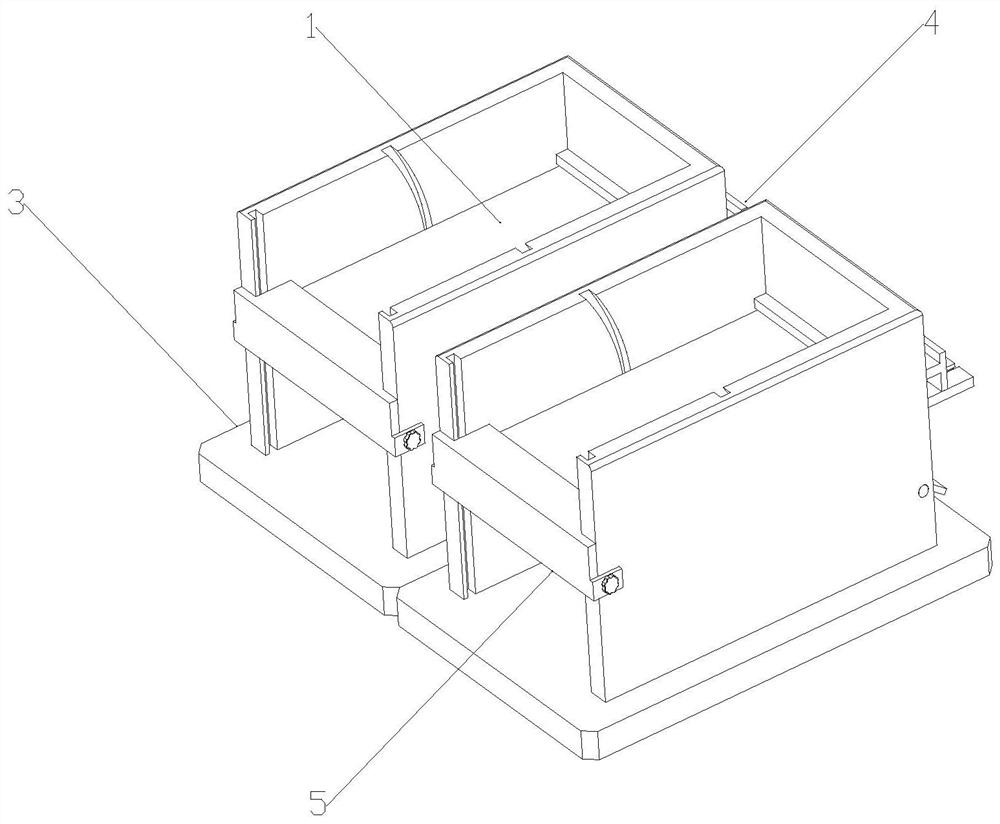

Self-adaptive positioning nut riveting tool and method

PendingCN112246987ASolve the problem of low qualified rate of rivetingGuaranteed coaxialityMetal-working feeding devicesPositioning devicesEngineeringScrew thread

The invention discloses a self-adaptive positioning nut riveting tool and method. The self-adaptive positioning nut riveting tool comprises an ejector rod, a positioning pressing sleeve, a tool base,a conical ejector head and an end face positioning sleeve. The tool base is of an opening structure, and a through hole is formed in one side of an opening and used for containing a rivet shaft nut. Athreaded through hole is formed in the other side of the opening, and the axis of the through hole is coaxial with that of the threaded through hole. The positioning pressing sleeve is cylindrical, athreaded through hole is formed in the central axis of the positioning pressing sleeve, the positioning pressing sleeve is rotationally connected with the end face positioning sleeve, and a through hole is formed in the central axis of the end face positioning sleeve. The positioning pressing sleeve penetrates the threaded through hole to press the end face positioning sleeve against the circumferential mounting face of a rivet shaft nut mounting hole in a workpiece, and the positioning pressing sleeve is in threaded connection with the tool base through the positioning sleeve. The ejector rod is cylindrical and is rotationally connected with the conical ejector head. The ejector rod penetrates the threaded through hole in the center of the positioning pressing sleeve to press the conicalejector head against the rivet shaft nut of the workpiece, and the ejector rod is in threaded connection with the positioning pressing sleeve through the ejector rod.

Owner:AECC AVIATION POWER CO LTD

Polystyrene foam compound light sandwich panel using slags

InactiveCN101638925ALightweight and high strengthWith thermal insulationSolid waste managementBuilding componentsThermal insulationSlag

The invention belongs to the technical field of novel building materials and relates to a light sandwich panel which uses slags as main surface materials and is manufactured by compounding on a polystyrene foam plastic panel core material, wherein, the sandwich panel is provided with ladder-shaped, triangular or semi-circular grooves at both sides. The surface materials coated on the exterior of the polystyrene foam plastic panel in the invention are manufactured by the following raw materials in parts by weight: 100 parts of slag powder, 2-7 parts of sulphate aluminium cement, 1.5-5.5 parts of desulfurized building gypsum, 0.5-5 parts of mirabilite and 4-11 parts of quicklime; the mass ratio of the water to the raw materials is 0.45 to 0.70. The product of the invention has the performance up to the national quality standard, is light in weight and high in strength, has the functions of thermal insulation, sound insulation and the like, and is a wall material that can be applied to frame-structured buildings.

Owner:UNIV OF JINAN

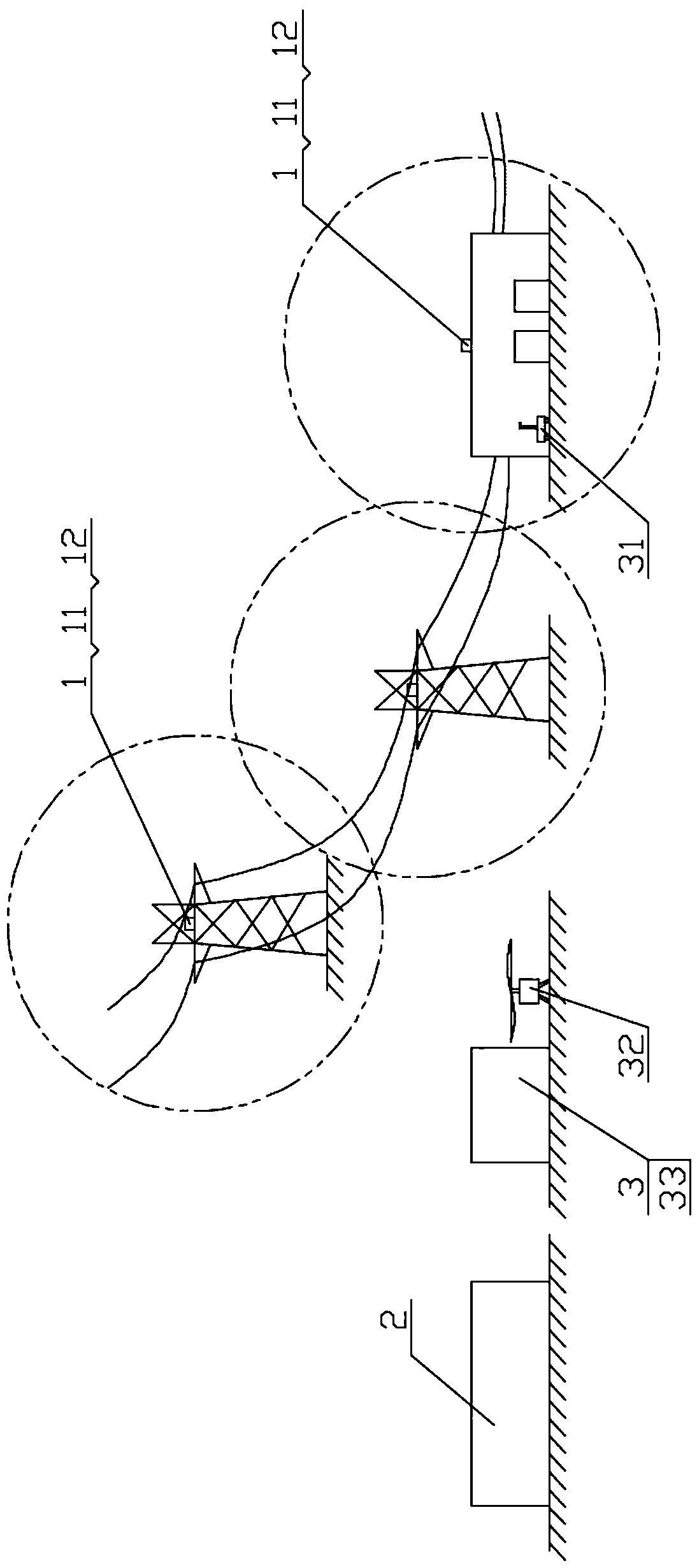

Power transmission and transformation intelligent monitoring and controlling maintenance system and usage method thereof

ActiveCN105375383AAvoid direct observation of stains on the surface of the lineAvoid problems such as cracksProgramme controlComputer controlInformation processingElectric power transmission

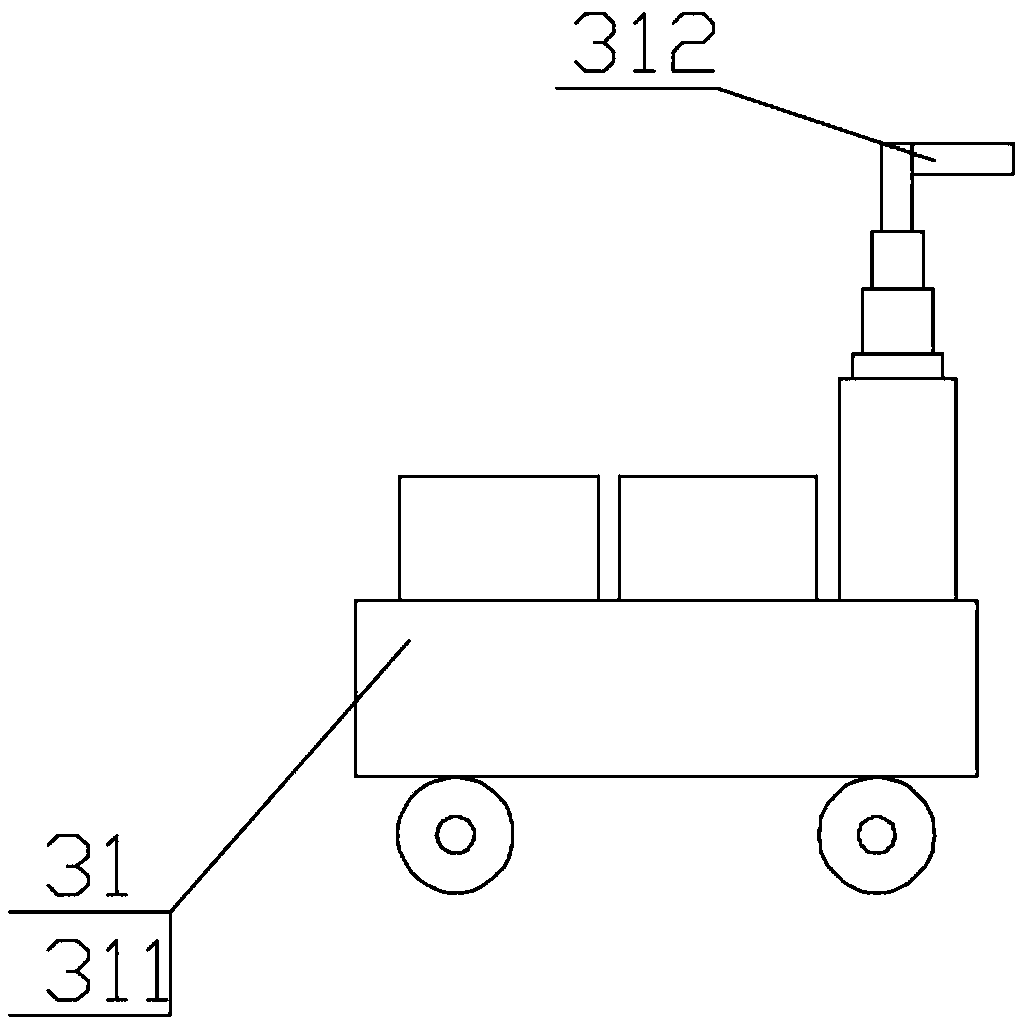

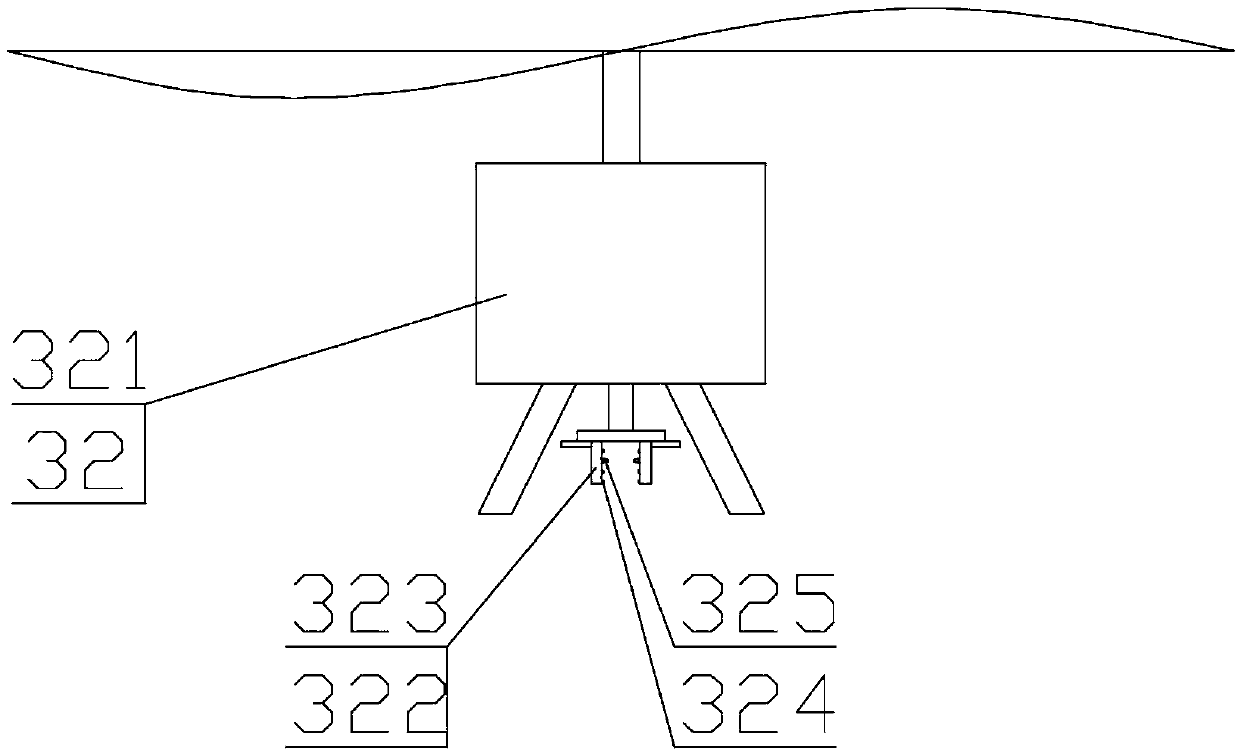

The invention discloses a power transmission and transformation intelligent monitoring and controlling maintenance system and a usage method thereof. The system comprises a monitoring and controlling unit (1), an information processing electric control unit (2) and a maintenance unit (3). The method comprises: employing the monitoring and controlling unit controlled by a micro computer to perform real-time monitoring and controlling on a tower mechanism and electric power utilities in a power transmission and transformation station; uploading monitoring and controlling information to the central control computer of the information processing electric control unit; and the central control computer performing centralized control: performing ground maintenance on power transmission and transformation station internal equipment through a ground maintenance component (31), and performing air maintenance on the tower mechanism and power transmission lines through an air maintenance component (32). The power transmission and transformation intelligent monitoring and controlling maintenance system realizes automatic operation, has high intelligent degree and higher maintenance efficiency, and can save labor force resources and avoid safety risks of manual operation.

Owner:XUZHOU DKEC ELECTRICAL TECH

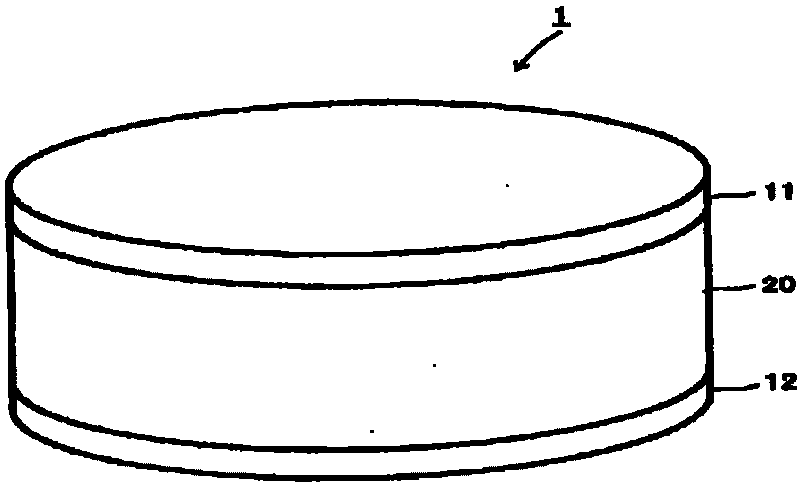

Semiconductor ceramic material and NTC thermistor

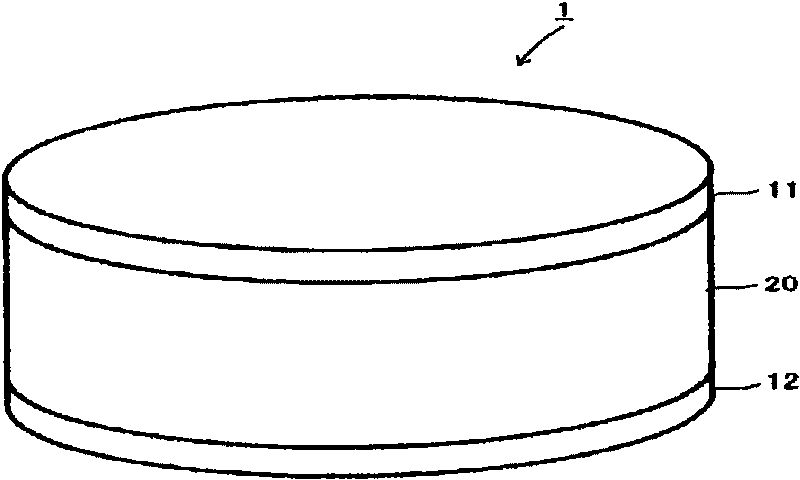

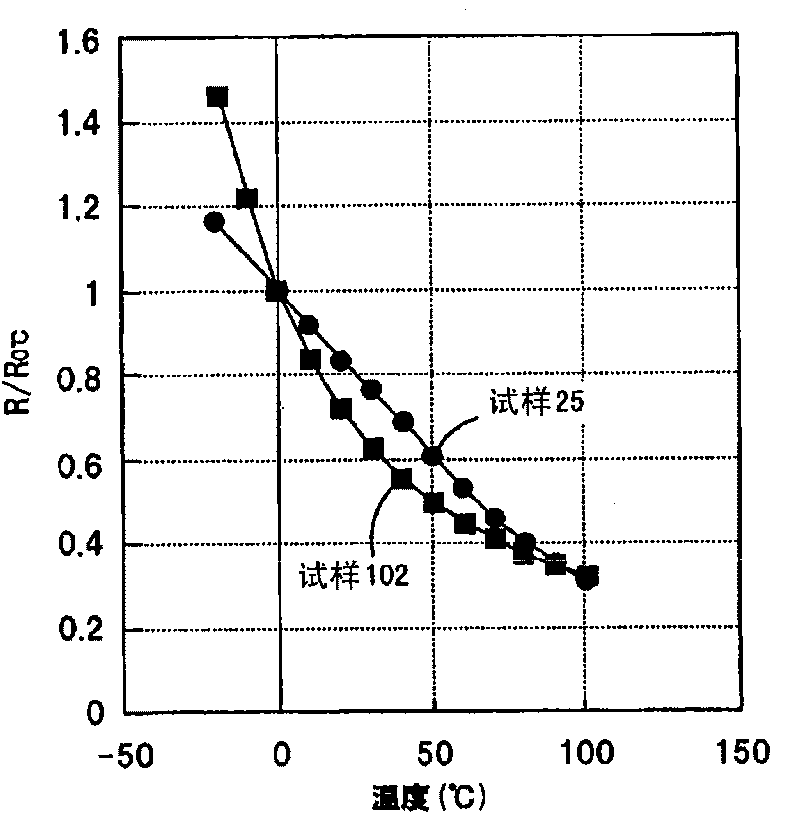

InactiveCN101765569AEasy to provideProvides linearity and easyNegative temperature coefficient thermistorsResistor manufactureElectrical resistance and conductanceThermistor

Provided is an NTC thermistor having excellent linearity of resistance temperature characteristics by using only one kind of semiconductor ceramic material without depending on combination of two or more kinds of materials. As a semiconductor ceramic material, which constitutes a ceramic element (20) for an NTC thermistor (1) and has a negative resistance temperature characteristic, a material composed of an oxide expressed as (La1-alphaBaalpha)xMnyOz (where, z is a number determined by values of x and y and satisfies the electroneutrality conditions as ceramic). When x=1 and y=0.8 to 1.5, an inequality of 0.60<=alpha<=0.75 is satisfied, and when x=1 and y=1.7 to 2.3, an inequality of 0.50<=alpha<=0.63 is satisfied.

Owner:MURATA MFG CO LTD

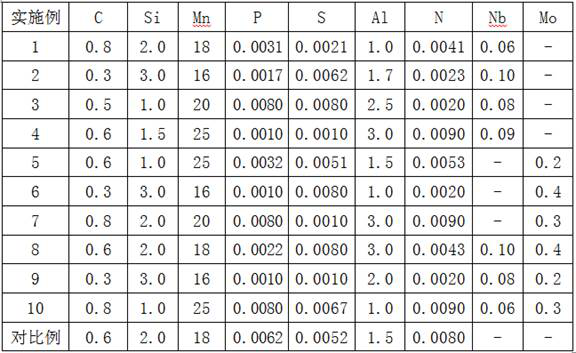

Highly-thermoplastic high-manganese and high-aluminum TWIP steel and production method thereof

The invention discloses highly-thermoplastic high-manganese and high-aluminum TWIP steel and a production method thereof. The highly-thermoplastic high-manganese and high-aluminum TWIP steel is prepared from the following chemical components in percentage by mass: 0.3 to 0.8 percent of C, 1 to 3 percent of Si, 16 to 25 percent of Mn, 0.001 to 0.008 percent of P, 0.001 to 0.008 percent of S, 1 to 3 percent of Al, 0.002 to 0.009 percent of N, 0.06 to 0.1 percent Nb and / or 0.2 to 0.4 percent of Mo, and the balance of Fe and other inevitable trace elements. According to the TWIP steel, Nb and / or Mo are / is added into the steel, so that the thermoplasticity of the steel is improved. The precipitation of aluminum nitride at the grain boundary of the steel can be reduced, the occurrence rate of dynamic recrystallization of the steel is increased, the thermoplasticity of the high-manganese and high-aluminum TWIP steel for automobiles is remarkably improved, and the tensile strength of the steel is improved, so that the problems of surface defects, cracks and the like in the hot working process are solved.

Owner:HEBEI IRON AND STEEL

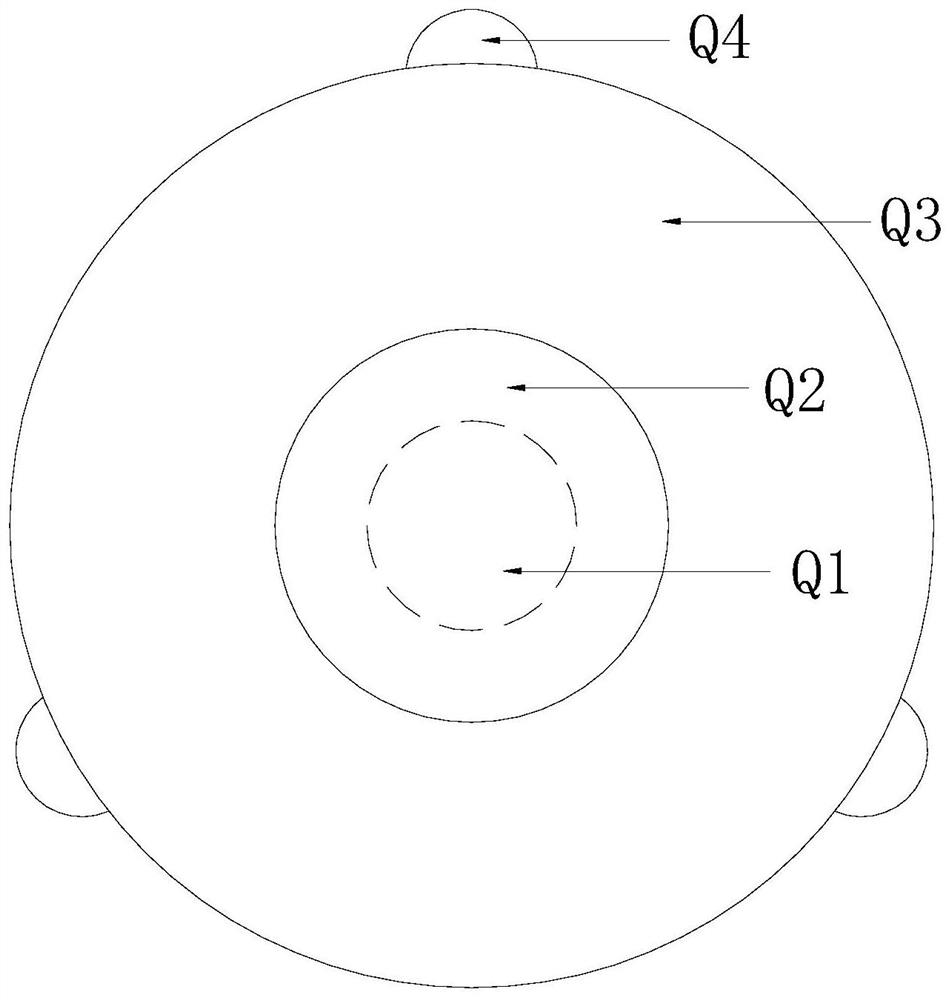

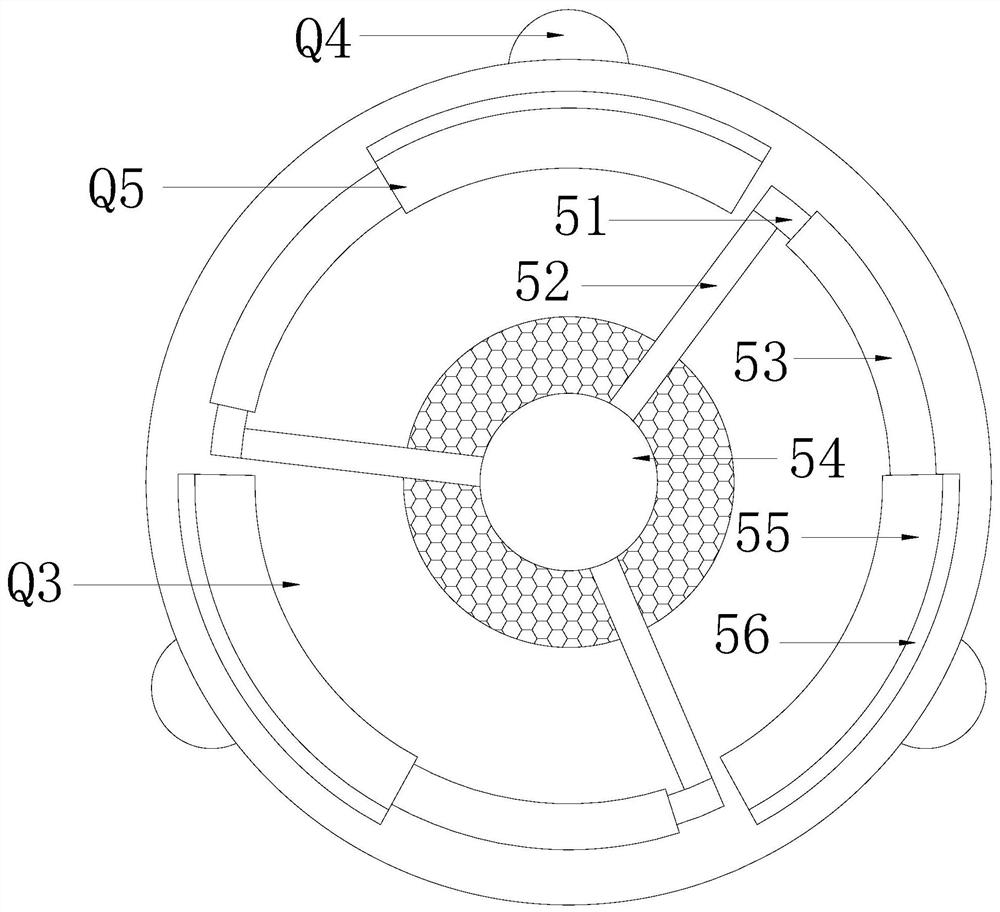

Internally-tangent type highly-efficient cutting device for glass tube

ActiveCN110845132AImprove cutting efficiencyGood effectElectrostatic separationGlass severing apparatusCircular discEngineering

The invention discloses an internally-tangent type highly-efficient cutting device for a glass tube. The internally-tangent type highly-efficient cutting device has a structure which comprises a device body, a liftable glass placement platform, glass tube clamp assemblies, a glass tube and a cutting unit, wherein the liftable glass placement platform is arranged on the device body; and a glass tube clamp assembly mechanically connected with the machine body is respectively arranged at two sides of the liftable glass placement platform. Compared with the prior art, the internally-tangent type highly-efficient cutting device provided by the invention has the following beneficial effects: a disc extends into the glass tube, and three cutting wheels synchronously extend outwards and rotate, sothe device can adapt to glass tubes with different calibers; the cutting wheels move from the inner wall of the glass tube to the outer wall of the glass tube for cutting the glass tube, so the device can prevent pressure on the glass tube from generation due to cutting from outside to inside, avoids problems like cracking of the glass tube, can guarantee the quality of the glass tube, can avoidpowder scraps from splashing outwards, and can collect the powder scraps generated in the cutting process and prevent the powder scraps from splashing on the basis of a triboelectrification principle.

Owner:江苏法玛施药用玻璃有限公司

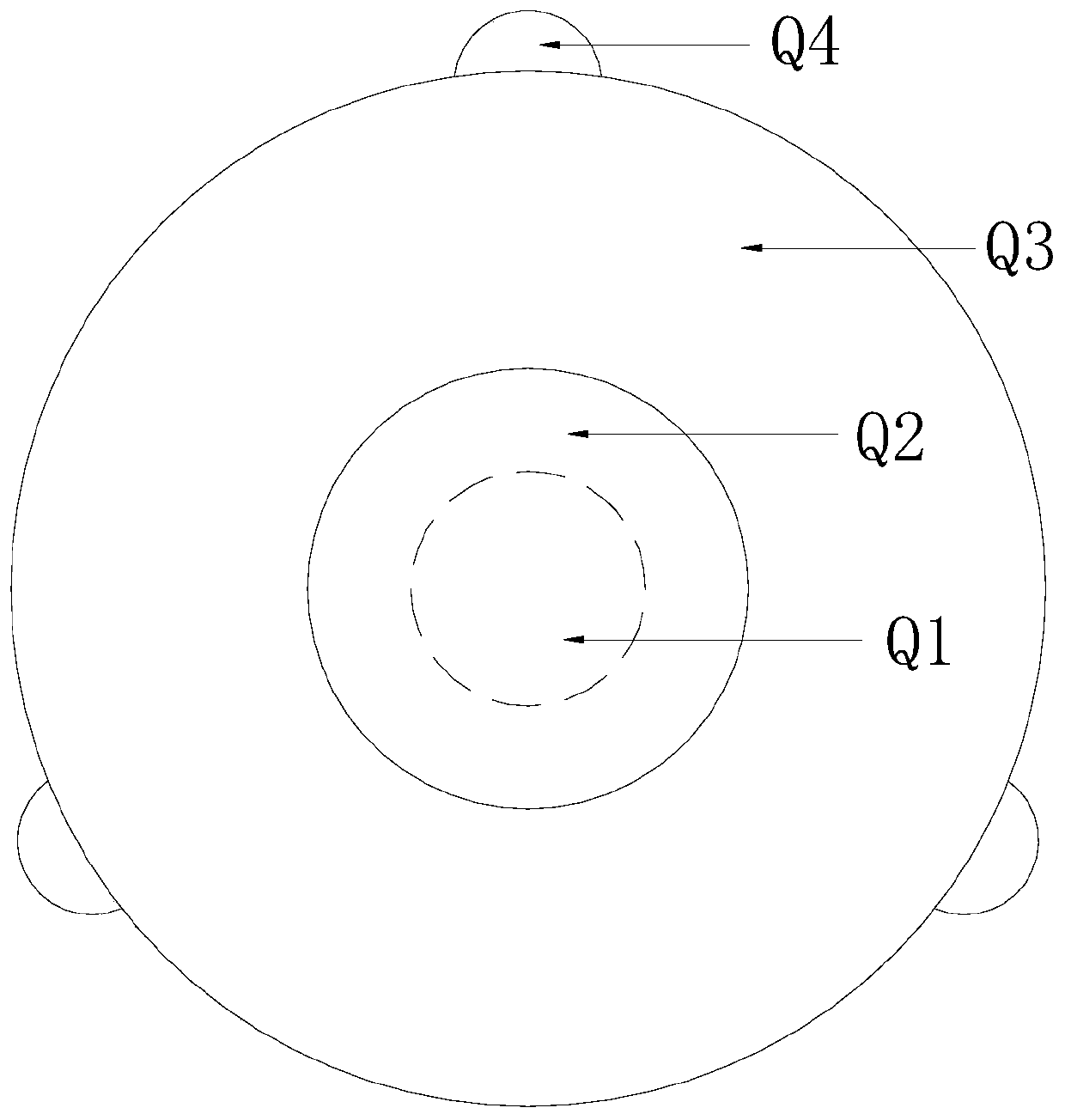

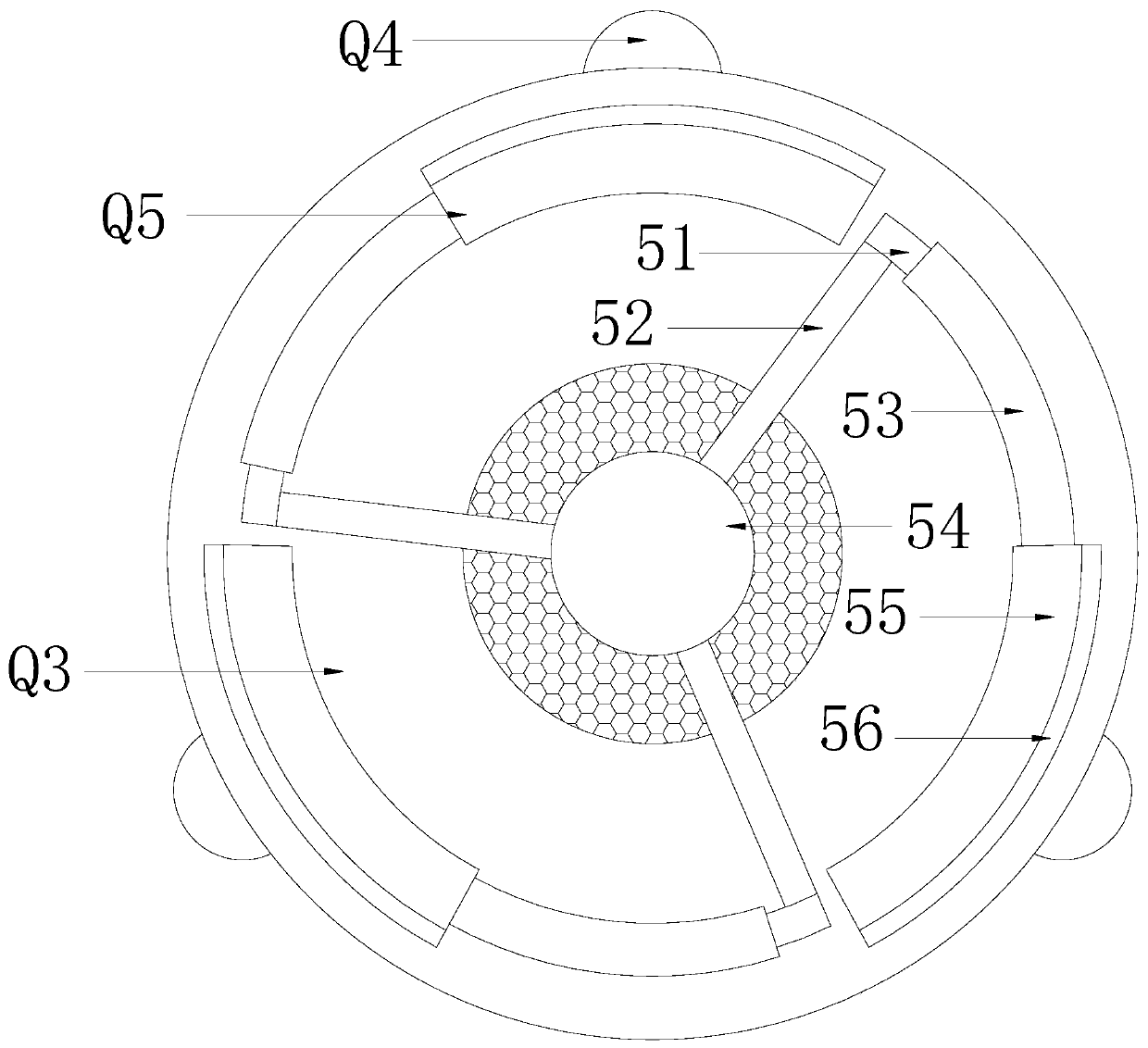

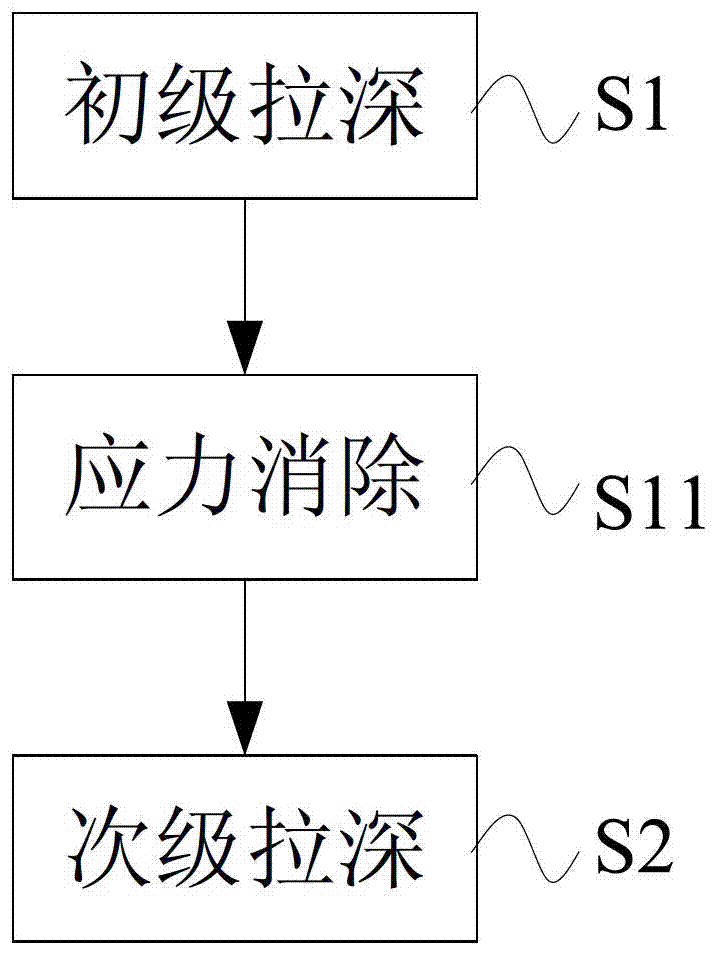

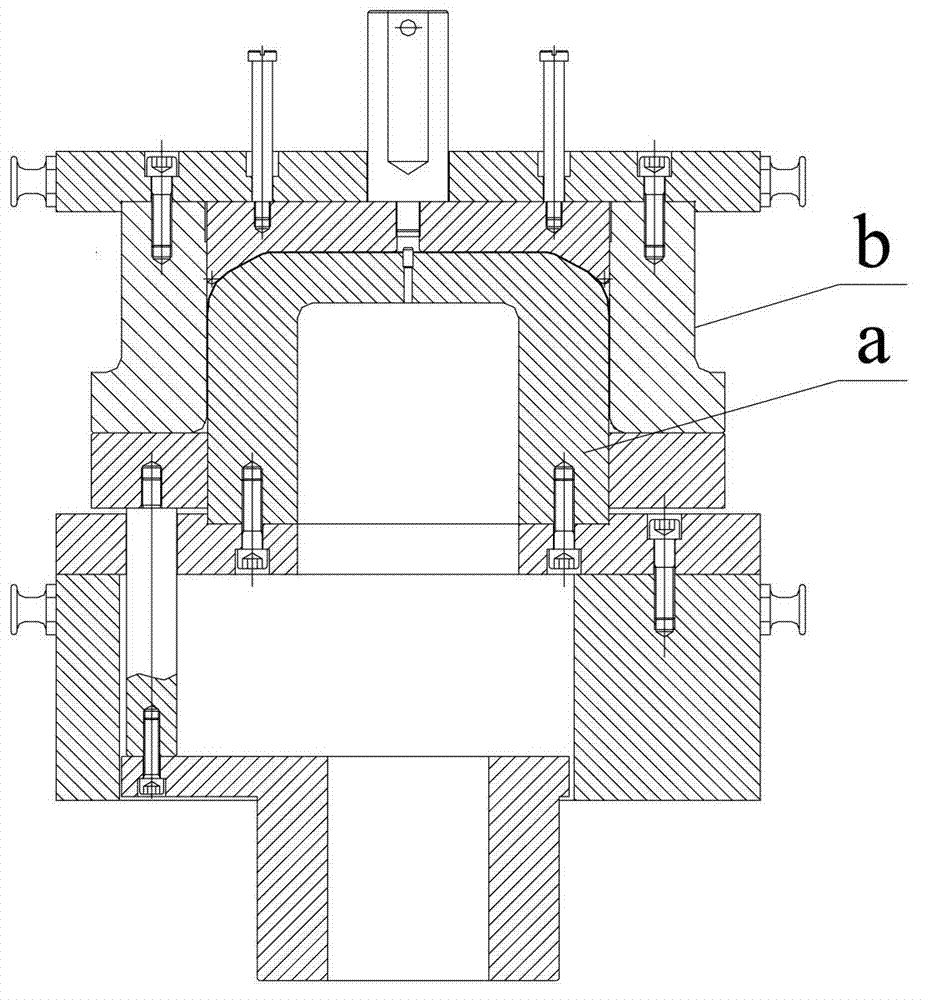

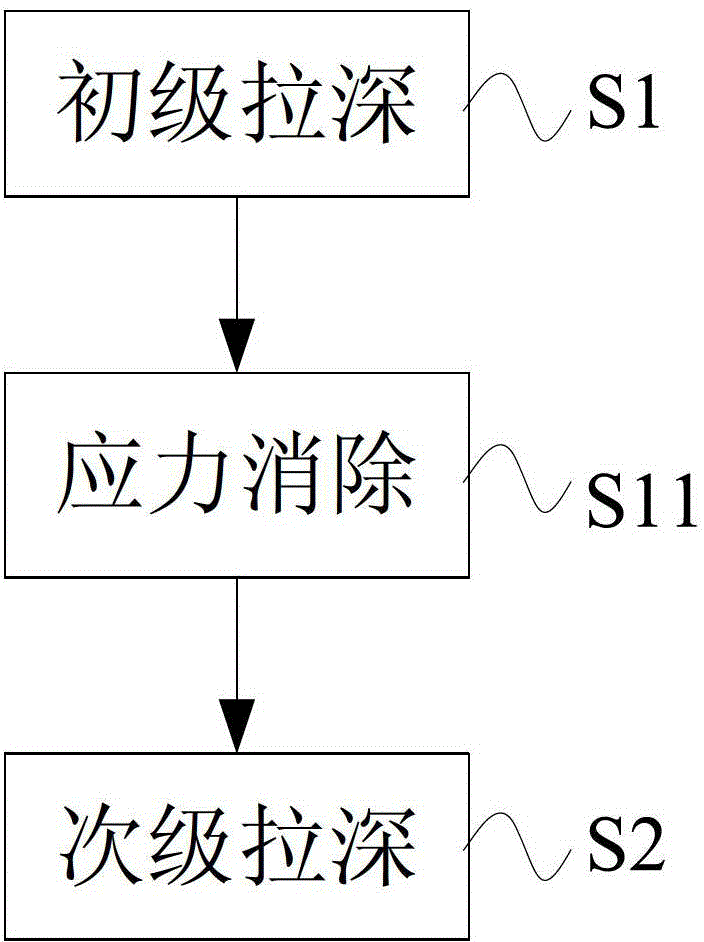

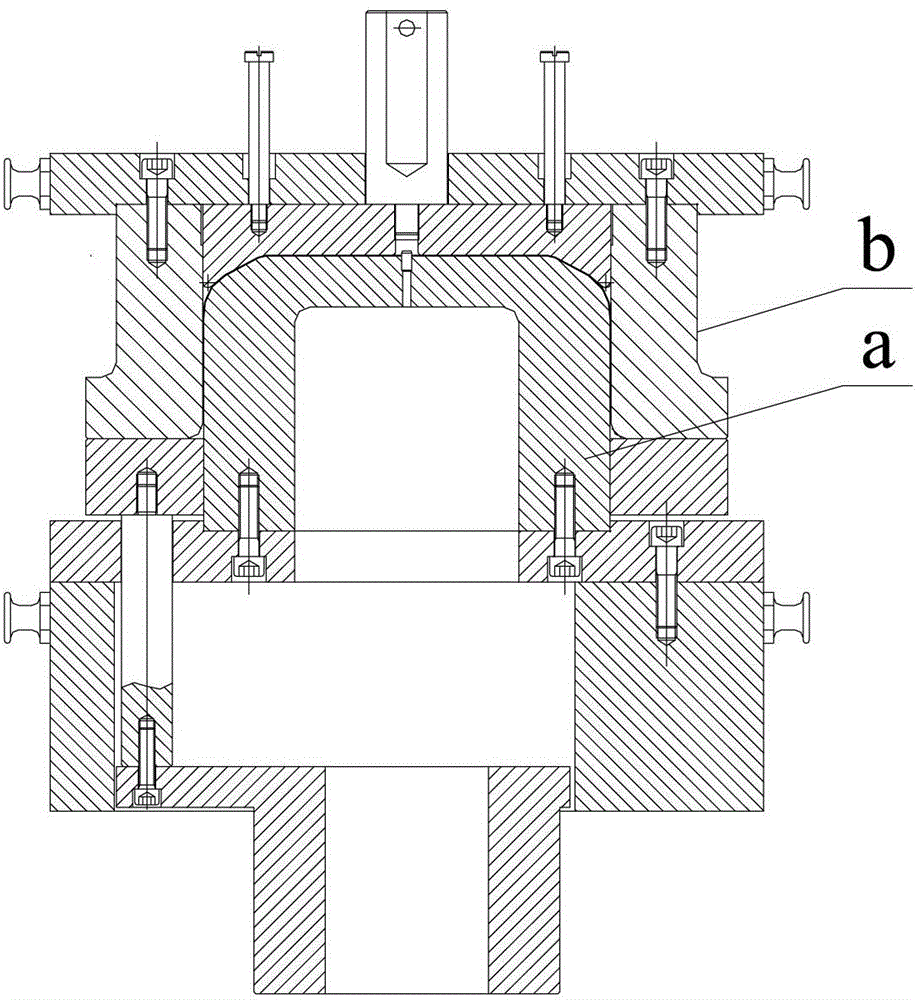

Formation method for machine case of combustor

The invention discloses a formation method for a machine case of a combustor. The formation method comprises the following steps: S1, initially drawing blanks to achieve initial formation of the blanks so as to carry out drawing and deformation in follow-up steps; S11, removing stress of the initially drawn blanks; and S2, secondarily drawing the blanks, and forming. According to the formation method, a two-grade drawing technology is adopted to reduce the difficulty at the technology for drawing at each time, and relatively lower drawing force is required for drawing each time, so that the requirements on processing equipment are reduced. With the adoption of the formation method, the circumstances of relatively high variation of the strength and hardness of metal materials can be effectively avoided, so relatively lower formation pressure is generated during forming the blanks by the formation method; and meanwhile, the operation of frequently annealing in the process can be saved, thereby reducing the complexity of a manufacture technology for the machine case of the combustor.

Owner:CHINA HANGFA SOUTH IND CO LTD

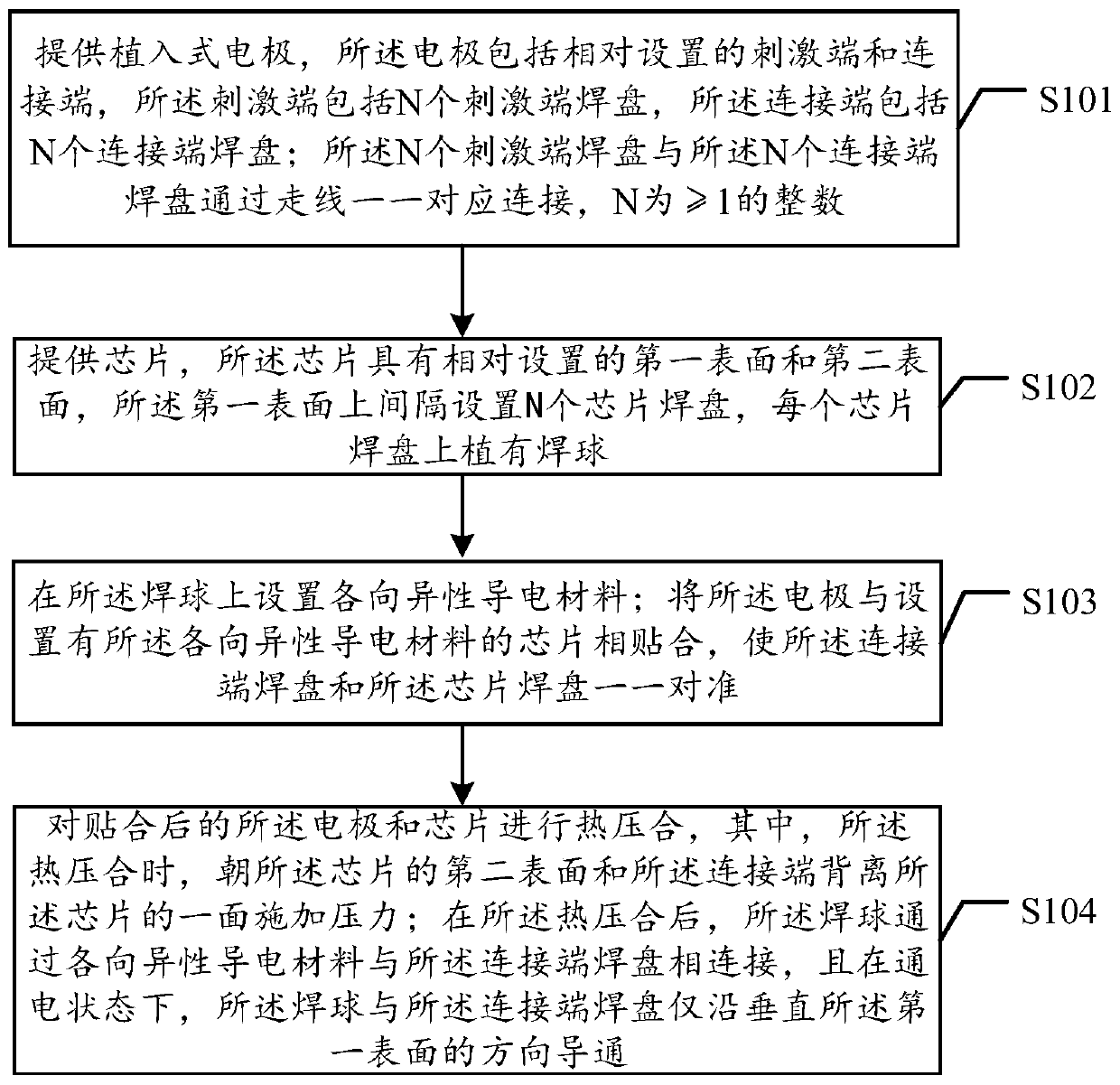

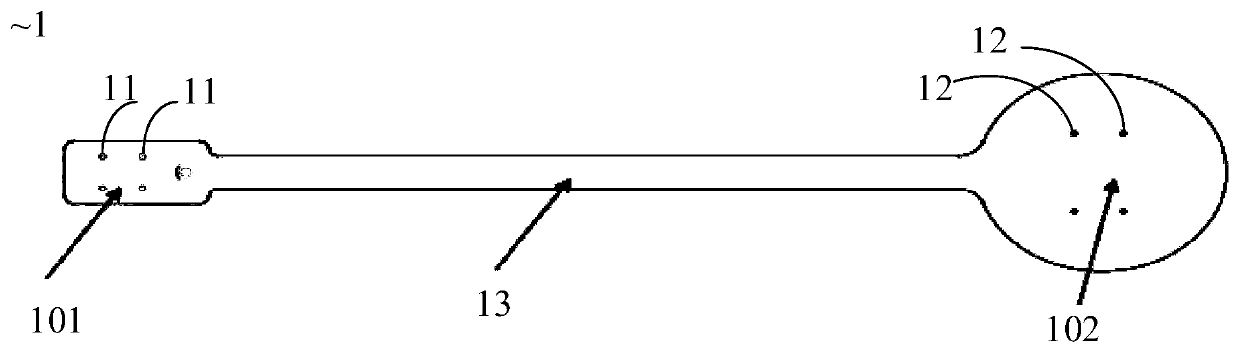

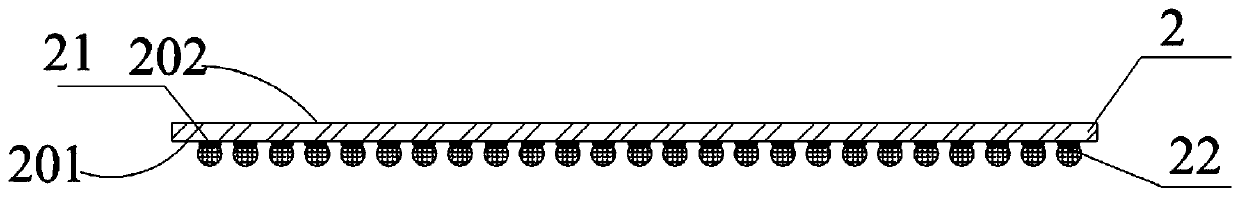

Implantable medical device and manufacturing method thereof

PendingCN111111006AImprove connection efficiencyImprove conduction rateSemiconductor/solid-state device detailsSolid-state devicesImplantable ElectrodesHigh density

The invention provides a manufacturing method of an implantable medical device. The manufacturing method comprises the following steps: providing an implantable electrode, wherein the electrode comprises a stimulation end and a connecting end, and the connecting end is provided with N connecting end bonding pads; providing a chip, wherein N chip bonding pads are arranged on the first surface of the chip at intervals; arranging an anisotropic conductive material on the chip bonding pads, and attaching the electrode to the chip bonding pads, so that the connecting end bonding pads and the chip bonding pads are aligned one by one; and carrying out hot pressing on the electrode and the chip which are attached, applying pressure to the second surface of the chip and the surface, facing away from the chip, of the connecting end, connecting the chip bonding pads with the connecting end bonding pads through the anisotropic conductive material, and conducting the chip bonding pads and the connecting end bonding pads only in the direction perpendicular to the first surface in a power-on state. According to the manufacturing method, an integrated circuit board is not needed for switching, theconnection efficiency, the connection strength and the conduction rate of the chip and the electrode are high, and the method is particularly suitable for connection of the high-density implantable electrode and the chip. The invention further provides an implantable medical device. The medical device is not provided with an integrated circuit board, and is simple in structure.

Owner:SHENZHEN INST OF ADVANCED TECH

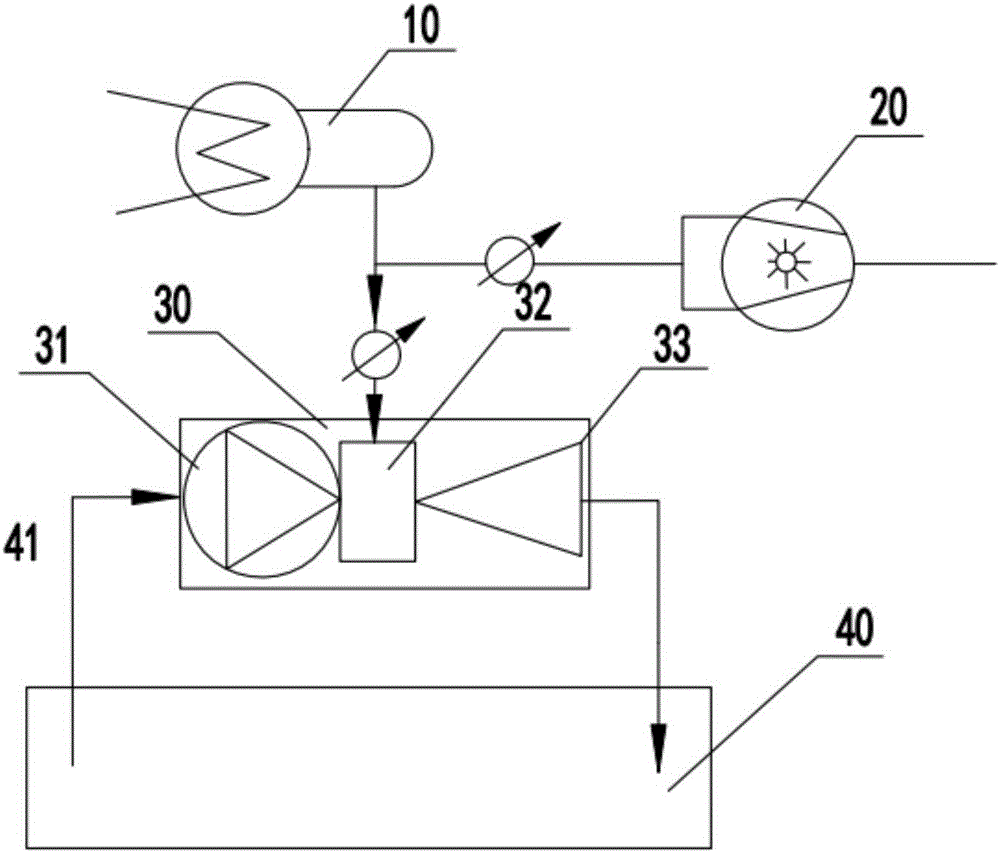

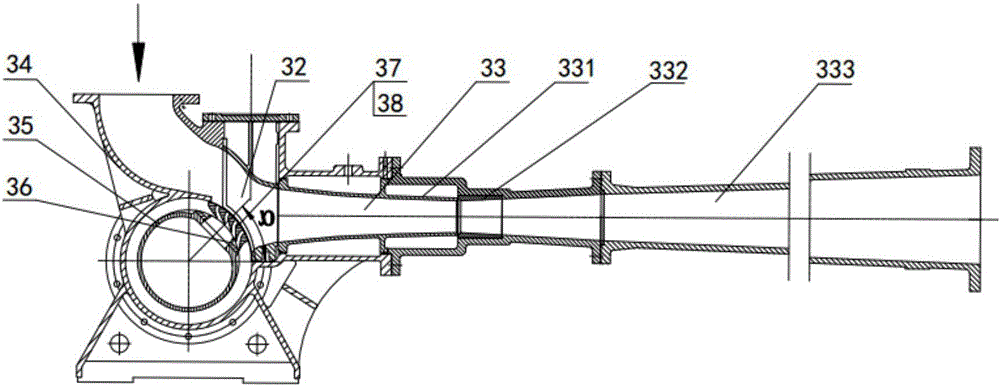

Jet vacuum system for energy conservation transformation of thermal power plant and vacuum maintenance method

PendingCN106802092AAvoid problems such as cracksReduce water consumptionSteam/vapor condensersRadial flow pumpsWater savingCavitation

The invention discloses a centrifugal jet vacuum system for energy conservation transformation of a thermal power plant in a region which is short of water resource and a vacuum maintenance method of the centrifugal jet vacuum system. The system comprises a condenser (10), and a water ring vacuum pump (20) and a centrifugal jet vacuum pump (30) which are respectively communicated with an extraction opening of the condenser (10), wherein a water inlet pipe and a water outlet pipe of the centrifugal jet vacuum pump (30) are connected with a water tank (40) respectively; an operating water system adopts secondary circulating water. The centrifugal jet vacuum system realizes the establishment and maintenance of the vacuum system through a mode of taking the centrifugal jet vacuum pump as a main body which is matched with the water ring vacuum pump, solves double problems of cavitation and energy consumption caused by taking water as the operating medium of a vacuum pump in a national thermal power plant, has the advantages of low work dissipation, small noise and low water consumption, and has remarkable economic benefit and water saving characteristic.

Owner:WUHAN WU PUMP PUMP MFG

Cracking-resistant cement mortar

The invention relates to a cracking-resistant cement mortar for building plastering, which belongs to building materials, which is prepared from perlite, cement and 801 glue with a volume ratio of (7.5-9):(2.8-3.3):1. The cement mortar solves the cracking, bubbling and poor bonding property problems of the prior plastering material; and has the advantages of high coagulation and setting speed, and good fire resistant, acid and alkali-resistant, thermal insulation and sound absorption properties.

Owner:SHANDONG WANXIN CONSTR

Polystyrene foam compound light sandwich panel using slags

InactiveCN101638925BEasy to installAvoid problems such as cracksSolid waste managementBuilding componentsThermal insulationSlag

The invention belongs to the technical field of novel building materials and relates to a light sandwich panel which uses slags as main surface materials and is manufactured by compounding on a polystyrene foam plastic panel core material, wherein, the sandwich panel is provided with ladder-shaped, triangular or semi-circular grooves at both sides. The surface materials coated on the exterior of the polystyrene foam plastic panel in the invention are manufactured by the following raw materials in parts by weight: 100 parts of slag powder, 2-7 parts of sulphate aluminium cement, 1.5-5.5 parts of desulfurized building gypsum, 0.5-5 parts of mirabilite and 4-11 parts of quicklime; the mass ratio of the water to the raw materials is 0.45 to 0.70. The product of the invention has the performance up to the national quality standard, is light in weight and high in strength, has the functions of thermal insulation, sound insulation and the like, and is a wall material that can be applied to frame-structured buildings.

Owner:UNIV OF JINAN

A fiber grating inclination sensor made of all glass

ActiveCN112344881BAvoid problems such as cracksSolution to short lifeUsing optical meansFiberGlass cover

The invention discloses a fiber grating inclination sensor made of all glass, which comprises a glass cover, a glass cylinder, a glass block, a cross glass rod, an equal-strength tempered glass beam, a first fiber grating, and a second fiber grating; the glass cylinder The inner wall of the upper part is provided with an internal thread, which is connected with the external thread of the cylindrical surface of the glass cover to form a closed space; the equal-strength tempered glass beam is fixed on the glass cover, and the cross glass rod is fixed on an equal-strength tempered glass rod. Below the glass beam, the glass block is fixed on the lower end of the cross glass rod; the first fiber grating and the second fiber grating are fixed on the surface of the equal-strength tempered glass beam, and the tails of the first fiber grating and the second fiber grating The optical fiber at the end is led out from the optical fiber access hole of the glass cover. The invention solves the problems of low sensitivity, complex structure and long measurement time of the existing inclination sensor, prolongs the service life of the sensor and has wide application range.

Owner:胡仲春

Method for controlling quality of cement mortar flooring

InactiveCN104790636APrevent steppingAvoid the problem of uneven calenderingFlooringControl qualityCement mortar

The invention relates to a method for controlling the quality of cement mortar flooring. The method comprises the following steps that sand and cement are screened; the quality of the sand and the cement is strictly controlled, and the screened sand is flushed; the surface of a base layer is processed; masonry and rendering falling mortar, mud and sand on the surface of the base layer are thoroughly cleared away, cement and concrete blocks protruding out of the surface are chiseled away, and the surface of the base layer is flushed; the surface of the base layer is moistened; before plastering, the surface of the base layer is fully moistened through clear water, and accumulated water in a pit of the base layer is cleared away; mortar is prepared according to specified coordination and is stirred evenly; the cement mortar is leveled before initial setting, press polishing is conducted before final setting, and the cement mortar is pressed to form bright light finally; natural drying is conducted, the ground is hardened after a period of time, and watering and maintaining are conducted on the ground regularly for several days. According to the method, checking is conducted from selecting of raw materials, problems produced in all the steps are avoided through an optimization mode, and the problems are avoided from beginning.

Owner:SICHUAN YAHAO REAL ESTATE DEV

A method for forming a casing for a combustion chamber

The invention discloses a formation method for a machine case of a combustor. The formation method comprises the following steps: S1, initially drawing blanks to achieve initial formation of the blanks so as to carry out drawing and deformation in follow-up steps; S11, removing stress of the initially drawn blanks; and S2, secondarily drawing the blanks, and forming. According to the formation method, a two-grade drawing technology is adopted to reduce the difficulty at the technology for drawing at each time, and relatively lower drawing force is required for drawing each time, so that the requirements on processing equipment are reduced. With the adoption of the formation method, the circumstances of relatively high variation of the strength and hardness of metal materials can be effectively avoided, so relatively lower formation pressure is generated during forming the blanks by the formation method; and meanwhile, the operation of frequently annealing in the process can be saved, thereby reducing the complexity of a manufacture technology for the machine case of the combustor.

Owner:CHINA HANGFA SOUTH IND CO LTD

A kind of inner cut cutting equipment for glass tube

ActiveCN110845132BImprove cutting efficiencyGood effectElectrostatic separationGlass severing apparatusCircular discGlass tube

The invention discloses an internal cutting type cutting device for glass tubes. Its structure includes a machine body, a liftable glass placement platform, a glass tube clamp assembly, a glass tube, and a cutting device. Both sides of the placing table are provided with glass tube clamp assemblies mechanically connected to the machine body. Compared with the prior art, the invention has the beneficial effect of: the disc is inserted into the glass tube, and three cutting wheels are used to protrude and rotate synchronously. , can be adapted to glass tubes of different calibers. The cutting wheel moves from the inner wall of the glass tube to the outer wall of the glass tube to cut the glass tube, which can prevent the pressure from being cut from the outside to the inside of the glass tube, and avoid cracks in the glass tube, etc. The problem is that the quality of the glass tube can be guaranteed, and the powder chips can be prevented from splashing outward. Based on the principle of frictional electrification, the powder chips generated during cutting can be collected to prevent the powder chips from splashing.

Owner:江苏法玛施药用玻璃有限公司

Production method of medical CT spiral bead die body

PendingCN112120720AStacking AccurateWhen stacking, each blind hole is accurately distributed along the helixComputerised tomographsTomographyCrazingWhole body

The invention provides a production method of a medical CT spiral bead die body. According to the technical scheme, a processing method of integrated inlaying and forming of the die body and steel balls is abandoned. Specifically, a formed organic glass material block is processed into a plurality of ring-shaped objects with the equal inner diameters and the equal outer diameters through a lathe,then blind holes are formed in the surfaces of the ring-shaped objects, it is ensured that the blind holes are distributed along a spiral line when the ring-shaped objects are stacked, on the basis, the steel balls are directly embedded into the blind holes, and then the ring-shaped objects are stacked and bonded into a tubular whole body. Based on the principle, it can be ensured that the steel balls are accurately distributed in the die body along the spiral line, and meanwhile the problems of bubbles, cracks and the like caused by embedding of the steel balls in a polymerization process areavoided. The tubular die body formed through bonding is externally bonded with an outer sleeve, the bottom is sealed, and therefore, the medical CT spiral bead die body is obtained. By applying the production method, the yield can be remarkably increased, and a certain improvement effect is achieved on the detection effect of the medical CT spiral bead die body.

Owner:CHAOYANG BIOTECH

A prefabricated building energy-saving thermal insulation wall and its installation and assembly device

ActiveCN111997227BImprove insulation effectIncreased load-bearing capacityWallsClimate change adaptationThermal insulationBuilding energy

The invention discloses an energy-saving heat-preservation wall body of an assembled building and an installation and assembly device thereof, and relates to the construction field. The wall designed by the present invention includes a supporting frame, and a heat-insulating wall is arranged in the supporting frame, and a cover plate is arranged on the upper end of the heat-insulating wall, which can well protect the inner wall, and at the same time, the firmness between layers is guaranteed, improving The thermal insulation effect and load-bearing effect of the wall are improved; at the same time, after the overall installation and assembly device designed by the present invention is fixed to the wall, the outer baffle plate and the second receiving plate are respectively attached to the outer wall of the forming frame and the upper end of the cover plate, To achieve the purpose of limiting the two sides of the wall, after fixing the two sides of the wall, the whole wall is in a horizontal state, and the first receiving plate and the second receiving plate are attached to the upper end of the cover plate respectively, so that the cover plate and the resistant When the alkali protective layer is bonded and formed by an adhesive, the whole is parallel and has a higher flatness, which improves the quality of the wall and avoids problems such as cracks during installation.

Owner:湖北博浩百联建设工程有限公司

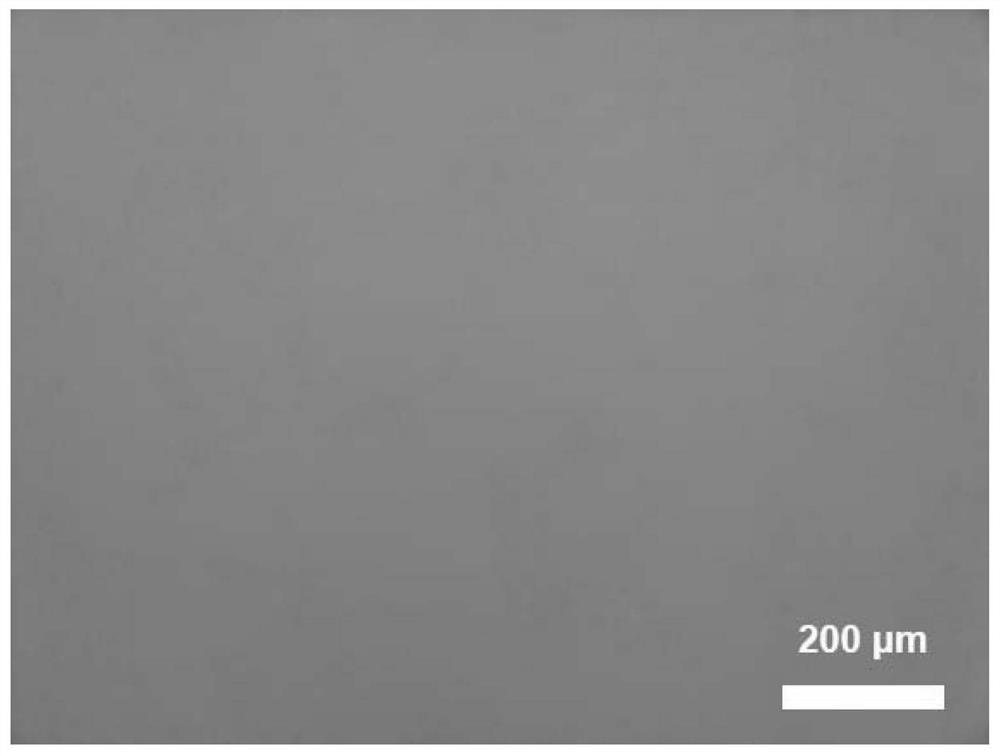

Copper film catalyst for CVD (Chemical Vapor Deposition) growth of graphene and application of copper film catalyst

ActiveCN112916004ASimple structureEasy to manufactureGrapheneMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention relates to a copper film catalyst for CVD (chemical vapor deposition) growth of graphene and application of the copper film catalyst. The copper film catalyst comprises a quartz plate which is subjected to surface hydrophobic treatment and serves as a base material, and a copper film formed on the surface of the base material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

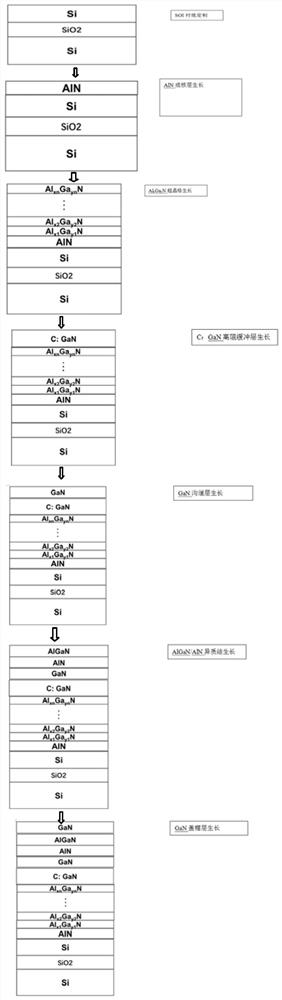

Silicon on insulator (SOI)-based GaN wafer and preparation method thereof

PendingCN113257909AQuality improvementAchieve integrationSolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionLattice mismatch

The invention relates to an SOI-based GaN wafer and a preparation method thereof. The GaN wafer sequentially comprises an SOI substrate, an AlN nucleating layer, an AlxGayN superlattice, a carbon-doped gallium nitride C: GaN buffer layer, a GaN channel layer, an AlGaN / AlN heterojunction and a GaN cap layer from bottom to top. Optimized SOI customized parameters and a C: GaN / AlGaN / AlN heterojunction technology are adopted, and lattice mismatch of heterojunction is utilized to match thermal mismatch between GaN and SOI, so that the problem that an SOI-based GaN wafer is excessively warped and even cracked in the high-temperature growing and cooling processes is avoided, and single-chip integration for GaN power electronics is facilitated.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

All-glass fiber Bragg grating tilt angle sensor

ActiveCN112344881AAvoid problems such as cracksSolution to short lifeUsing optical meansGlass fiberGlass cover

The invention discloses an all-glass fiber Bragg grating tilt angle sensor which comprises a glass cover body, a glass cylinder, a glass block, a cross glass rod, an equal-strength tempered glass beam, a first fiber Bragg grating and a second fiber Bragg grating. An internal thread is arranged on the inner wall of the upper part of the glass cylinder and is in threaded connection with an externalthread on the cylindrical surface of the glass cover body to form a closed space. The equal-strength tempered glass beam is fixed to the glass cover body, the cross glass rod is fixed to the lower portion of the equal-strength tempered glass beam, and the glass block is fixed to the lower end of the cross glass rod. The first fiber Bragg grating and the second fiber Bragg grating are both fixed tothe surface of the equal-strength tempered glass beam, and tail end optical fibers of the first fiber Bragg grating and the second fiber Bragg grating are both led out of an optical fiber access holeof the glass cover body. The problems of low sensitivity, complex structure, overlong measurement time and the like of the existing tilt angle sensor are solved, the service life of the sensor is prolonged, and the sensor has a wide application range.

Owner:胡仲春

Clamp for welding of exhaust system clamshell type rear muffling bag

InactiveCN108857208AAvoid problems such as cracksSituations to avoid sound-cancelling effectsAnalysing solids using sonic/ultrasonic/infrasonic wavesWelding/cutting auxillary devicesUltrasonic weldingEngineering

The invention discloses a clamp for welding of an exhaust system clamshell type rear muffling bag. The clamp structurally comprises a welding clamp main body, a clamping control pile, a supporting column, a fixing base and a limiting bottom plate, the clamping control pile is connected to the upper surface of the supporting column in a screwing mode through bolts, the other end of the clamping control pile is connected with the limiting bottom plate, one end of the bottom of the supporting column is perpendicularly welded to the right side surface of the upper portion of the fixing base, the welding clamp main body is arranged above the limiting bottom plate through nuts in a screwing connection mode, the cross section of the limiting bottom plate is of a rectangular structure, one end ofthe right side of the supporting column is screwed on the bottom surface of the limiting bottom plate through nuts, the welding clamp main body is provided with a fixing plate, a locking clamp and anultrasonic welding detection device. According to the clamp, the ultrasonic welding detection device is additionally arranged, the welding quality of a product can be detected in time after welding operation, the problems such as cracks due to welding are avoided, the welding quality can be improved, and the situation that the muffling effect occurs due to the cracks is avoided.

Owner:谢萍萍

Embedded saddle dedicated alloy material

InactiveCN103993247AImprove antioxidant capacityImprove corrosion resistanceSolution treatmentSolid solution

The invention discloses an embedded saddle dedicated alloy material which comprises the following components, by weight, 5-7% of Ni, 12-14% of Cr, 1.6-1.8% of Si, 0.1-0.3% of S, 0.25-0.3% of C, 0.1-0.3% of Mn, 0.05-0.08% of B, 0.2-0.5% of Si, 0.003-0.009% of P, 0.8-1.2% of W, 0.5-0.8% of Ti, 3.2-3.6% of compound rare earth and the balance Fe. A preparation method of the alloy material comprises the following steps: Step (1) the raw materials are sent into a forging furnace for forging; Step (2) a workblank is heated to 550-600 DEG C; Step (3) the blank undergoes solid solution treatment; Step (4) the blank is quenched and tempered; and Step (5) a finished product is obtained after being detected qualified.

Owner:WUXI HUAERTAI MACHINERY MFG

Fabricated building energy-saving thermal insulation wall body and mounting and assembling device thereof

ActiveCN111997227AQuality improvementImprove flatnessWallsClimate change adaptationThermal insulationBuilding energy

Owner:湖北博浩百联建设工程有限公司

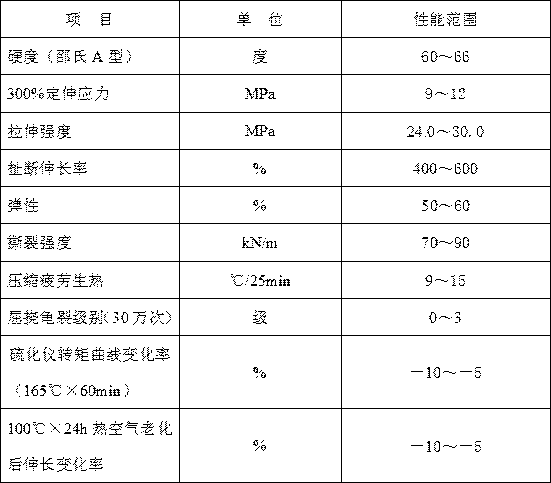

A low heat generation, high elasticity aviation radial tire shoulder pad rubber

The invention provides an airplane radial tire shoulder wedge with low heat generation and high elasticity properties. The airplane radial tire shoulder wedge is prepared from raw materials in parts by weight as follows: natural rubber, a reinforcing system, a silane coupling agent, an anti-ageing agent, a stabilizer and the like through banburying by a banbury mixer and extruding by an extruder, and is attached to the tire shoulder part. The airplane radial tire shoulder wedge has the advantages that the airplane radial tire shoulder wedge has low heat generation, high elasticity, good flexing resistance and good heat stability, the hardness and stress at definite elongation are reasonably matched with peripheral parts, and delamination caused by the fact that the tire shoulder wedge and the peripheral parts produce different deformation in a stress state can be prevented.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

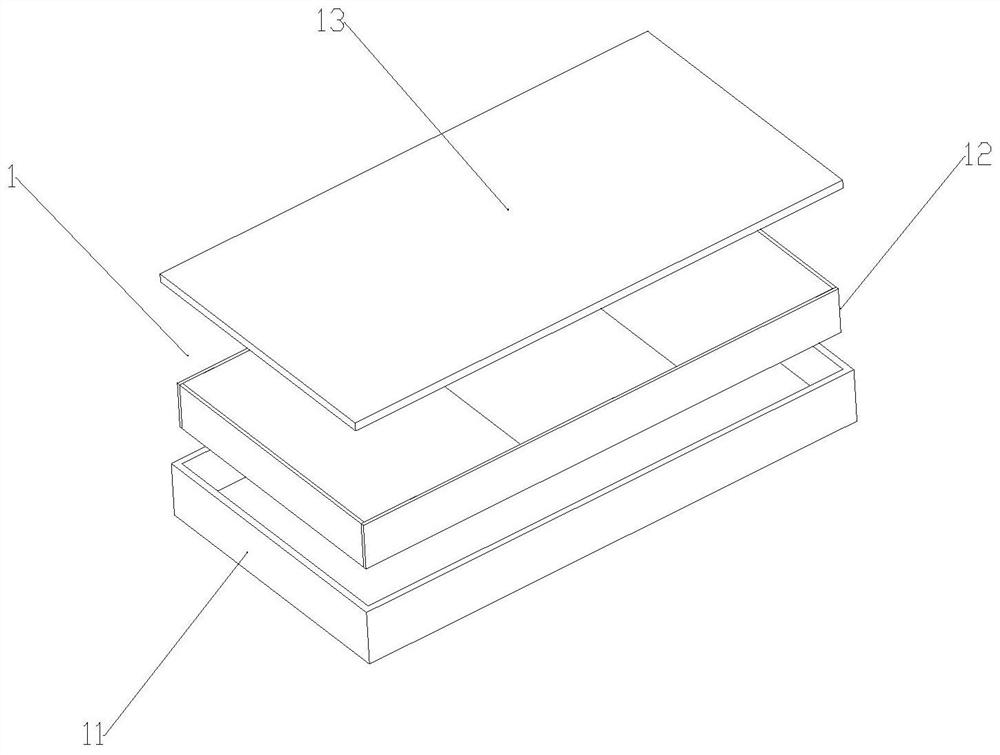

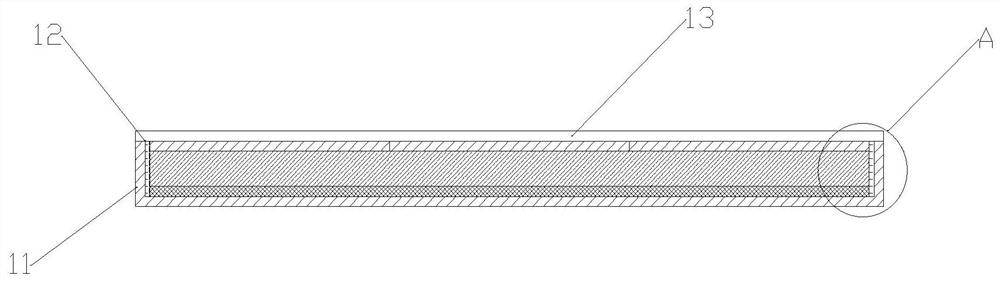

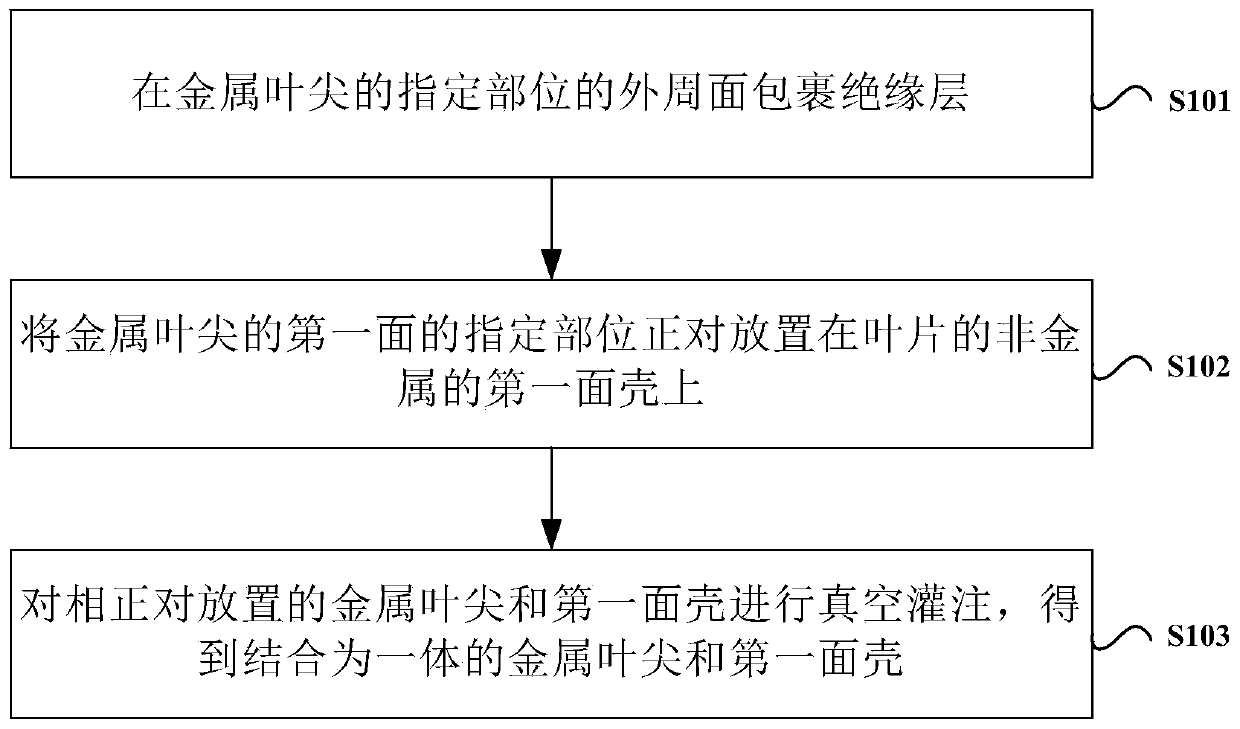

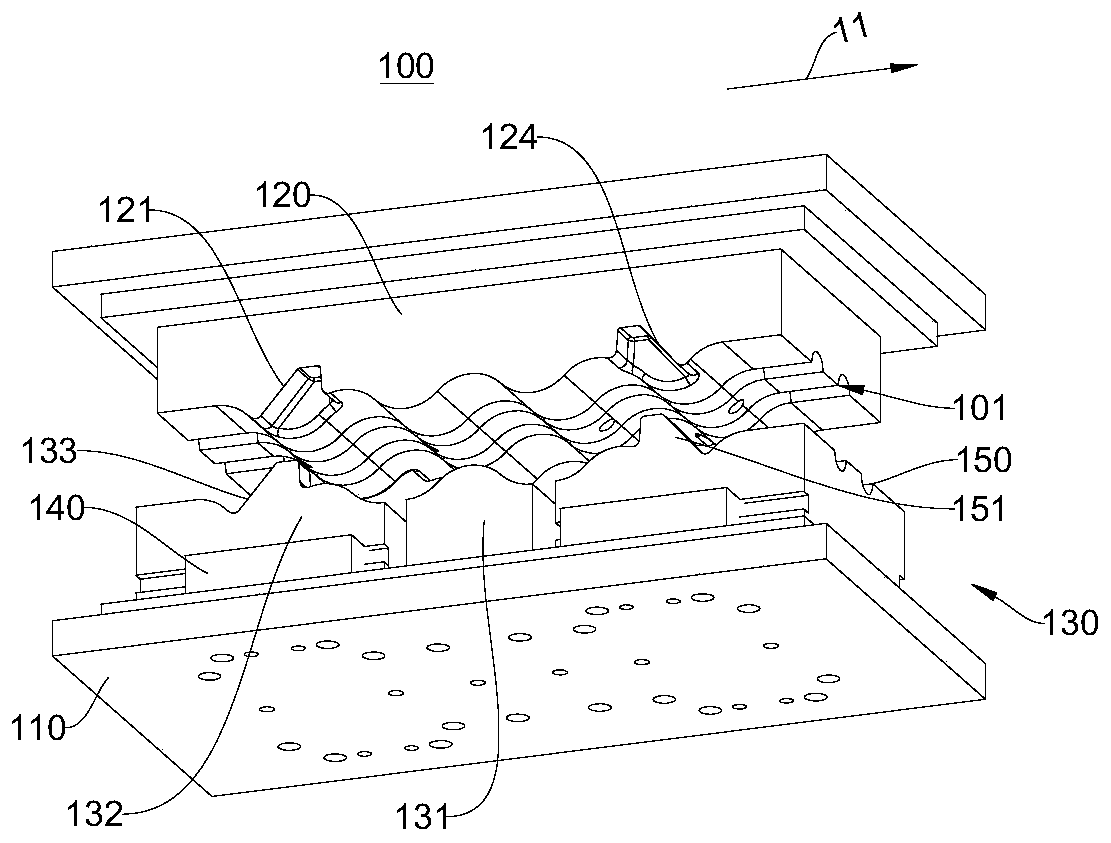

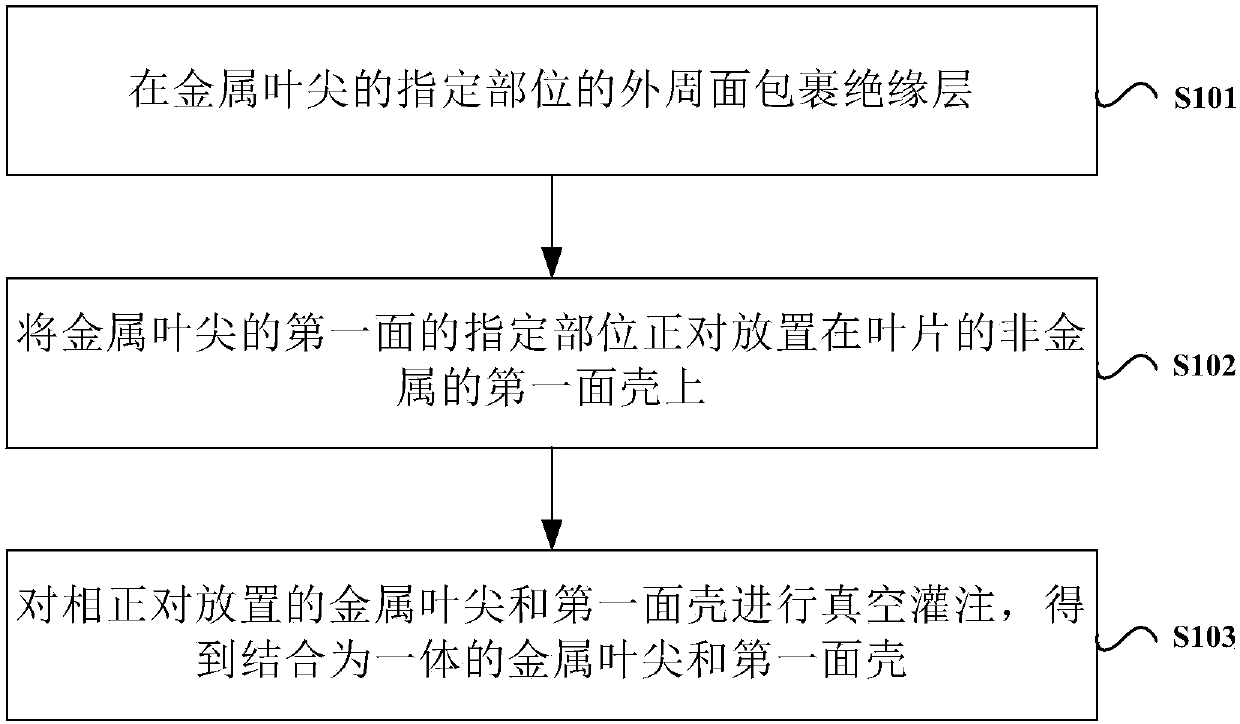

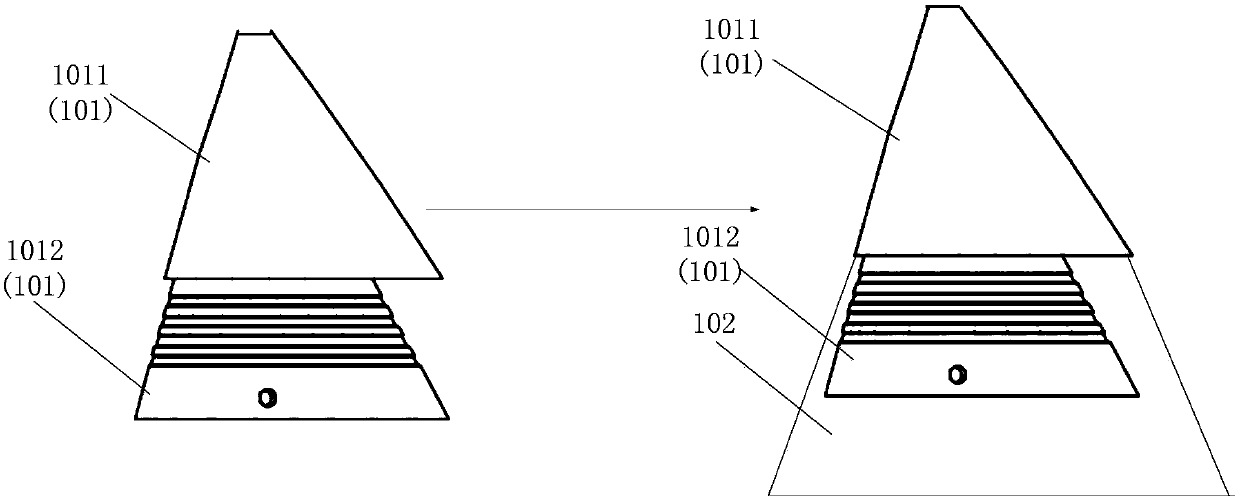

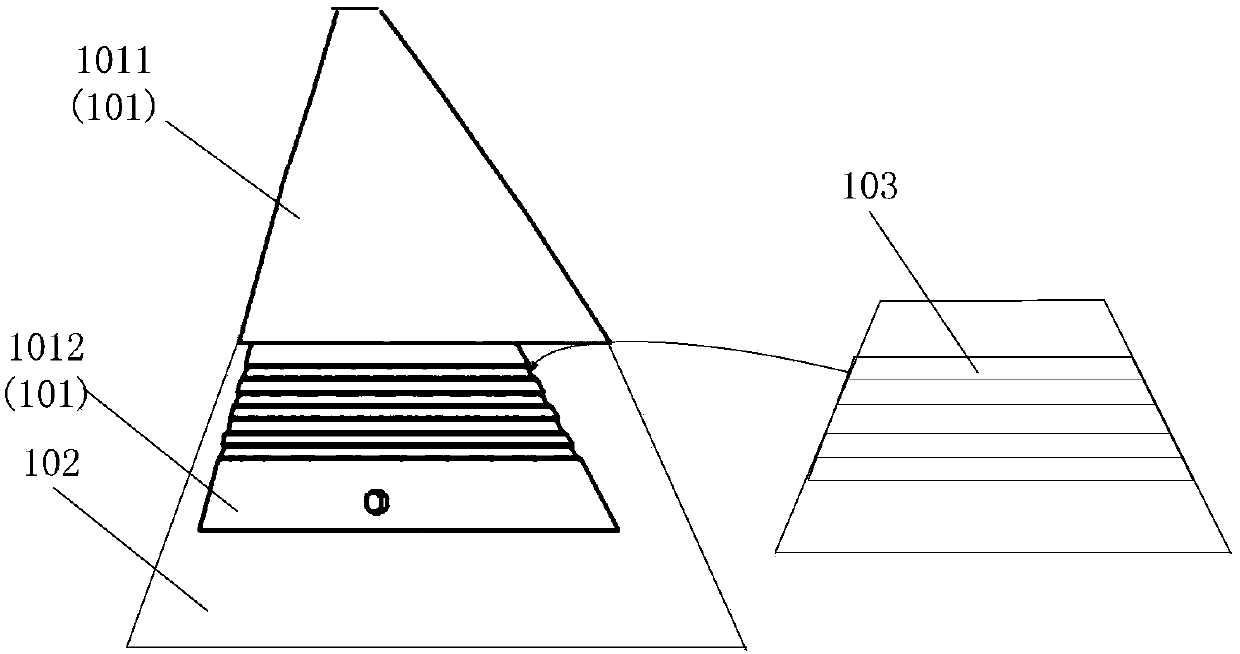

Blade tip of wind power generating set and preparation method thereof

ActiveCN109958586BQuality improvementAvoid misalignmentEngine manufactureFinal product manufactureEngineeringTurbine

The invention provides a blade tip of a wind generating set and a preparation method thereof. The preparation method comprises the following steps that an insulating layer is wrapped around the outerperipheral surface of a designated part of a metal blade tip body; the designated part of the first surface of the metal blade tip body is placed right opposite to a non-metal first surface shell of ablade; and vacuum perfusion is carried out on the metal blade tip body and the first surface shell which are placed opposite to each other so as obtain the metal blade tip body and the first surfaceshell which are combined into a whole. According to the blade tip of the wind generating set and the preparation method thereof, the metal blade tip body and the first surface shell (such as a leewardsurface shell) of the blade are fixedly combined into a whole through a vacuum perfusion method, so that the problem that a metal blade tip body and a blade are staggered can be solved, the quality of the blade tip is improved, and then the performance of the lightning-protection metal blade tip is ensured.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

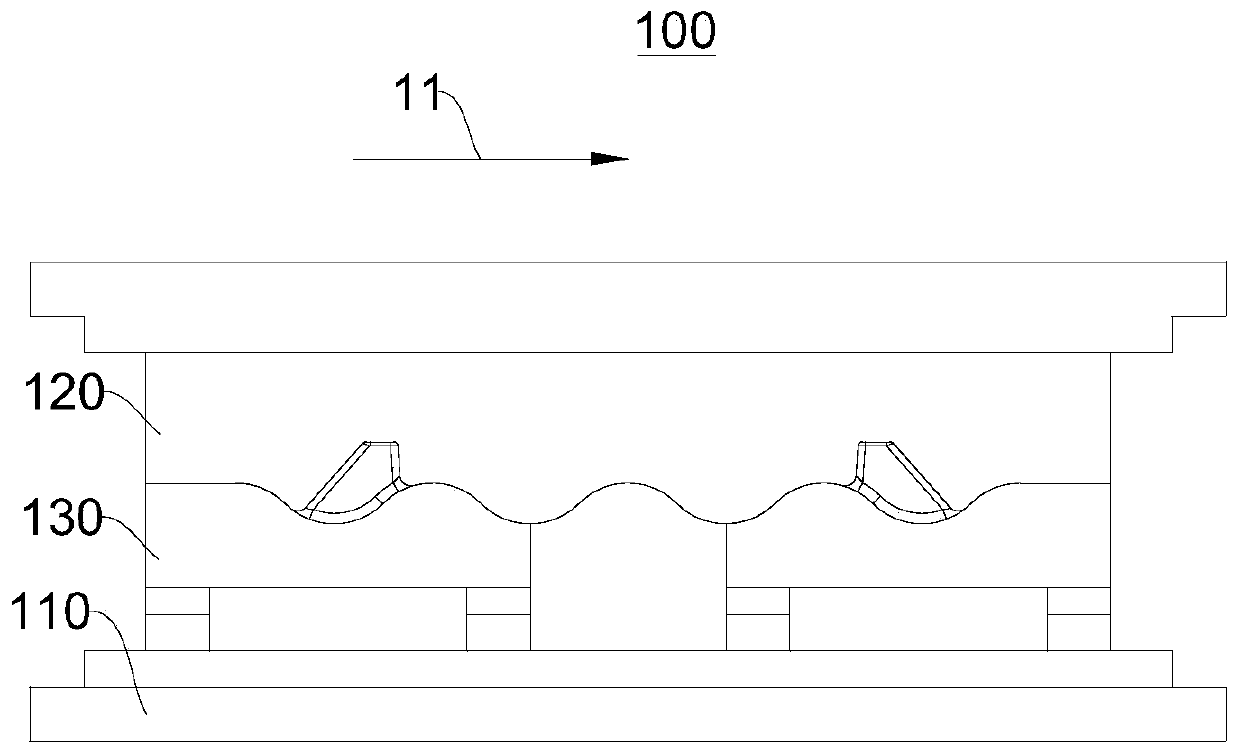

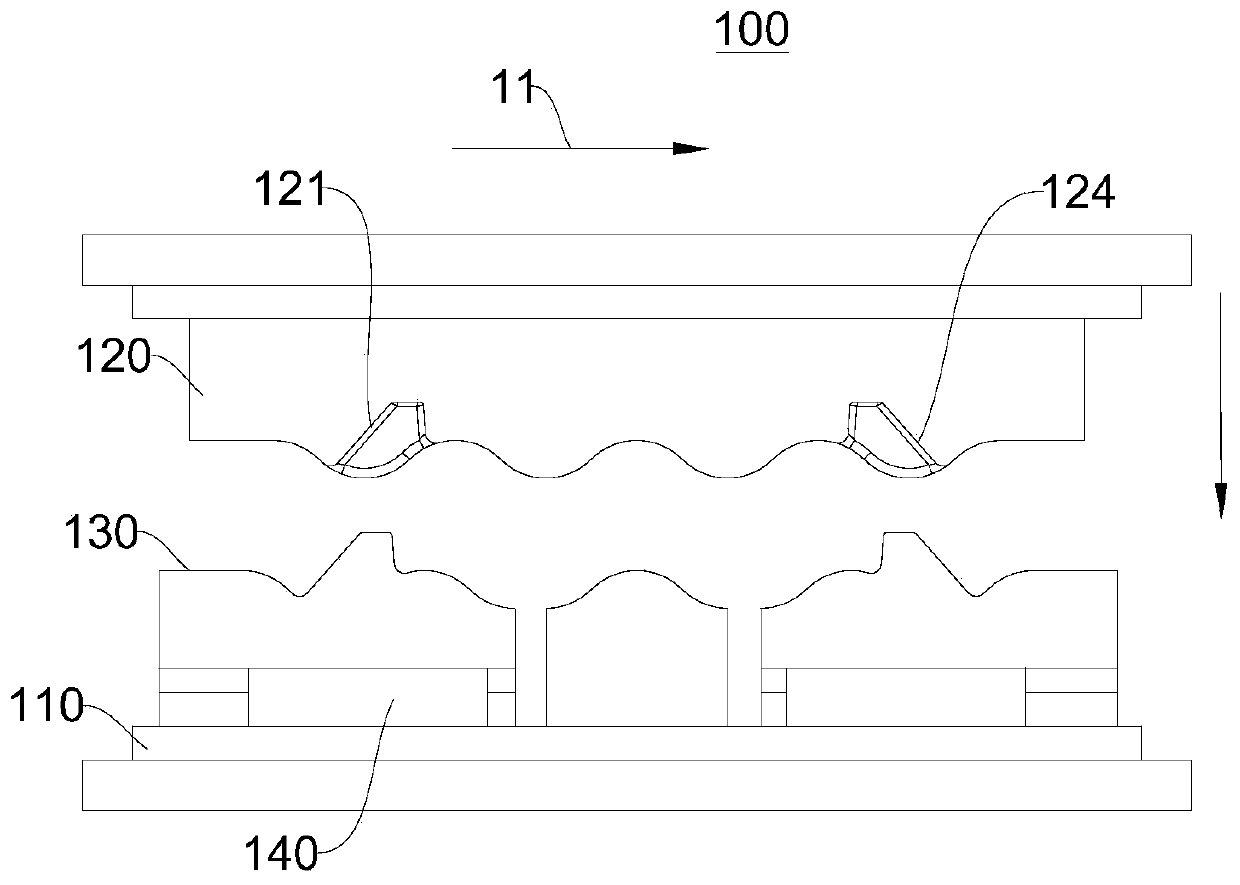

Bend pipe split mold and bend pipe manufacturing method

PendingCN110434237AAvoid uniformityAvoid problems such as cracksShaping toolsStress concentrationStraight tube

The invention relates to the field of bend pipe processing, and in particular to a bend pipe split mold and a bend pipe manufacturing method. The parting surface of the bend pipe split mold is a curved surface, and the bend pipe split mold is provided with a mold cavity extending in a first direction, and the bend pipe split mold comprises a base body, an upper mold and a lower mold assembly; thelower mold assembly comprises a fixed lower mold and a first sliding lower mold; the first sliding lower mold is provided with a first guiding part; the upper mole is provided with a second guiding part matching with the first guiding part, and when the upper mold is descending, the first guiding part can abut against the second guiding part and move oppositely so that the first sliding lower moldis close to the fixed lower mold and closes the mold. When the upper mold presses a straight pipe, the first sliding lower mold and the fixed lower mold are close to each other, and during the process of closing to each other, the bending stress of the straight pipe is released. The bend pipe split mold and the bend pipe manufacturing method can eliminate stress concentration, improve the uneventhickness of the bend pipe and improve the quality of the bend pipe.

Owner:HENAN YONGFUDE SCI & TECH CO LTD

Blade tip of wind generating set and preparation method thereof

ActiveCN109958586AQuality improvementAvoid misalignmentEngine manufactureFinal product manufactureEngineeringLightning

The invention provides a blade tip of a wind generating set and a preparation method thereof. The preparation method comprises the following steps that an insulating layer is wrapped around the outerperipheral surface of a designated part of a metal blade tip body; the designated part of the first surface of the metal blade tip body is placed right opposite to a non-metal first surface shell of ablade; and vacuum perfusion is carried out on the metal blade tip body and the first surface shell which are placed opposite to each other so as obtain the metal blade tip body and the first surfaceshell which are combined into a whole. According to the blade tip of the wind generating set and the preparation method thereof, the metal blade tip body and the first surface shell (such as a leewardsurface shell) of the blade are fixedly combined into a whole through a vacuum perfusion method, so that the problem that a metal blade tip body and a blade are staggered can be solved, the quality of the blade tip is improved, and then the performance of the lightning-protection metal blade tip is ensured.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com