Jet vacuum system for energy conservation transformation of thermal power plant and vacuum maintenance method

A technology for vacuum system and energy-saving transformation, which is applied in the direction of radial flow pumps, non-variable pumps, steam/steam condensers, etc. It can solve problems such as difficult to meet, vacuum pump pumping capacity decline, blade breakage, etc., and achieve significant economic efficiency. Benefits, reduced power consumption, and low water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following, the present invention will be described in detail and specifically through specific examples, so as to better understand the present invention, but the following examples do not limit the scope of the present invention.

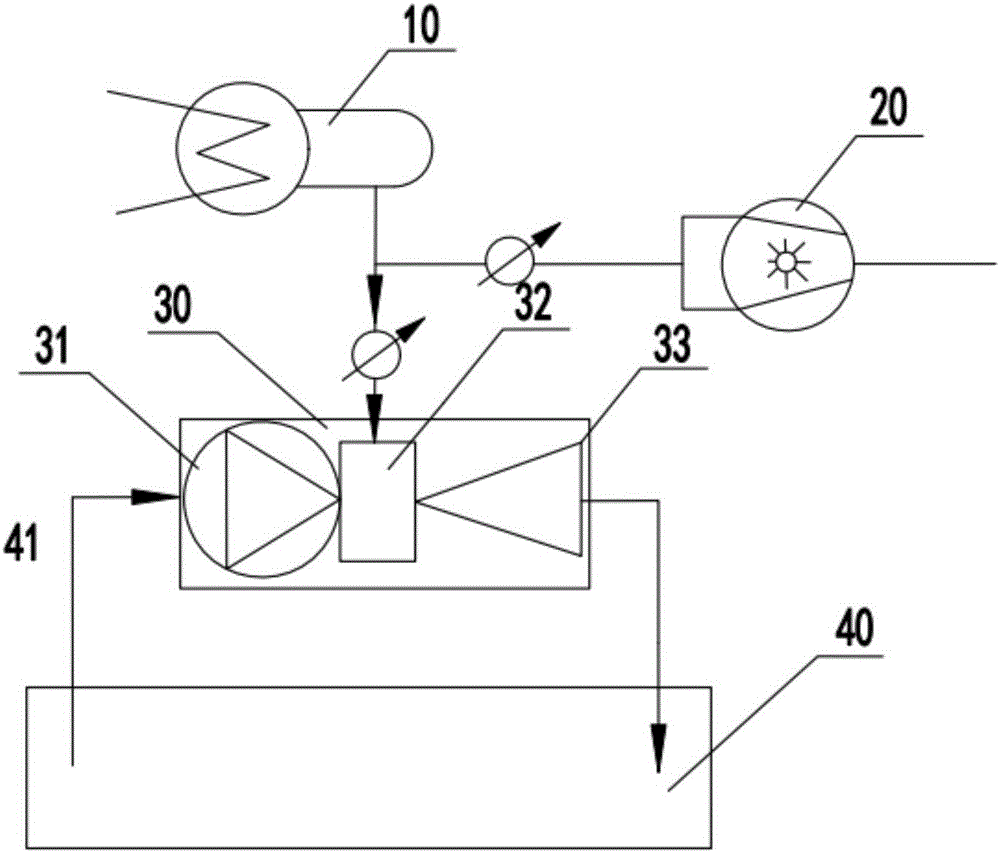

[0027] Such as figure 1 As shown, this embodiment proposes a centrifugal jet vacuum system for energy-saving transformation of thermal power plants, which is mainly aimed at areas with tight water resources. The centrifugal jet vacuum system is used for the energy-saving transformation of the condenser part of the vacuum system of the thermal power plant. The water inlet pipe and the water outlet pipe of the vacuum pump 30 are respectively connected with the pool 40, and the working water system is secondary circulating water. The centrifugal jet vacuum pump 30 is connected with the pool 40. The pool 40 is to ensure the working water of the centrifugal jet vacuum pump 30 on the one hand, and also has the function of dissipating the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com