Implantable medical device and manufacturing method thereof

A manufacturing method and technology of medical devices, applied in the field of medical devices, can solve problems such as chip and electrode connection, low conduction rate, and many cracks, and achieve the effects of avoiding virtual soldering, high conduction rate, and strong connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following are preferred embodiments of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can also be made, and these improvements and modifications are also considered as the present invention. protection scope of the invention.

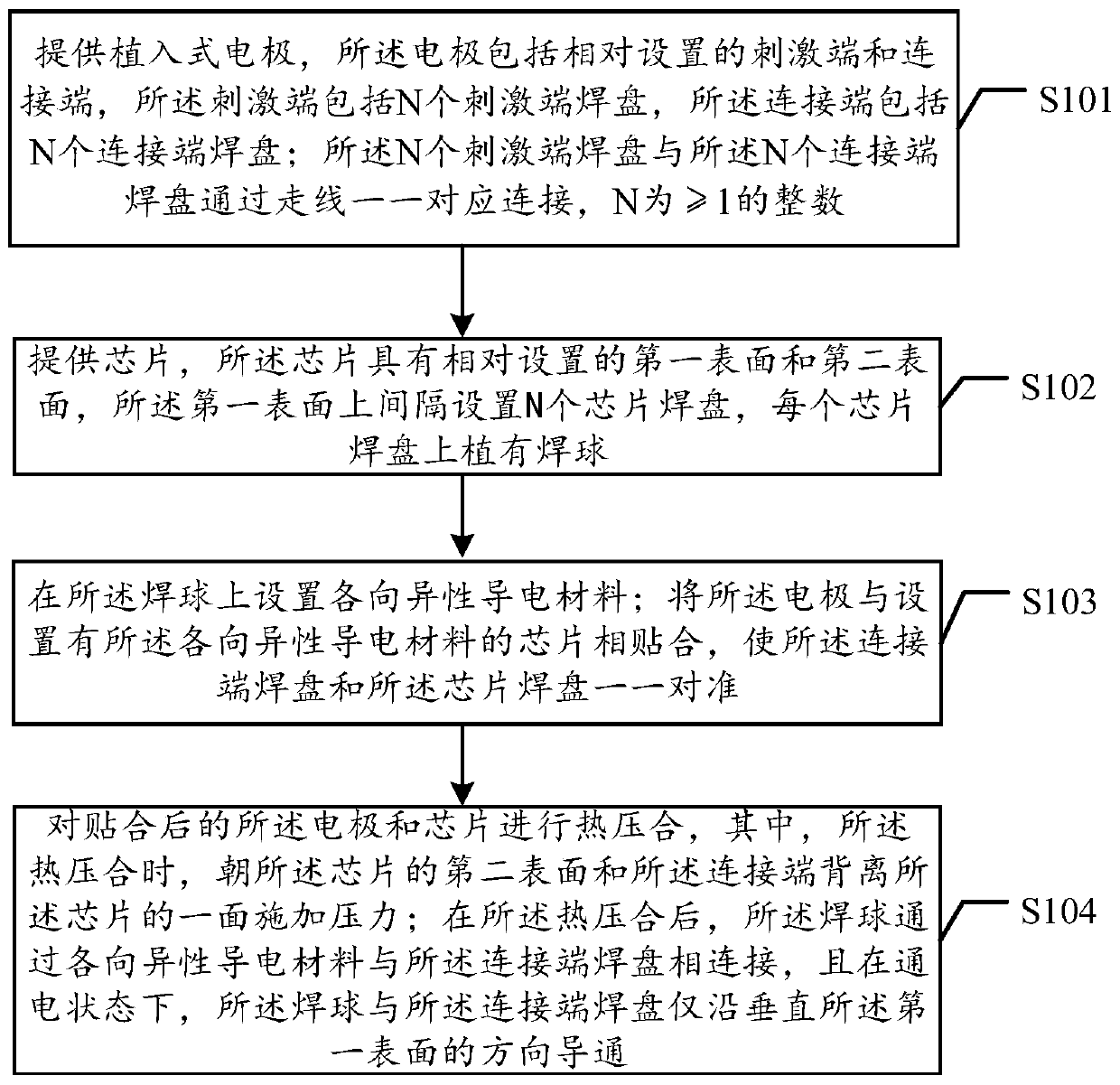

[0041] see figure 1 , figure 1 It is a flowchart of a manufacturing method of an implantable medical device disclosed in an embodiment of the present invention. This method is particularly suitable for the manufacture of high-density implantable medical devices.

[0042] Such as figure 1 As shown, the manufacturing method of the implantable medical device described in this embodiment includes steps S101, S102, S103 and S104.

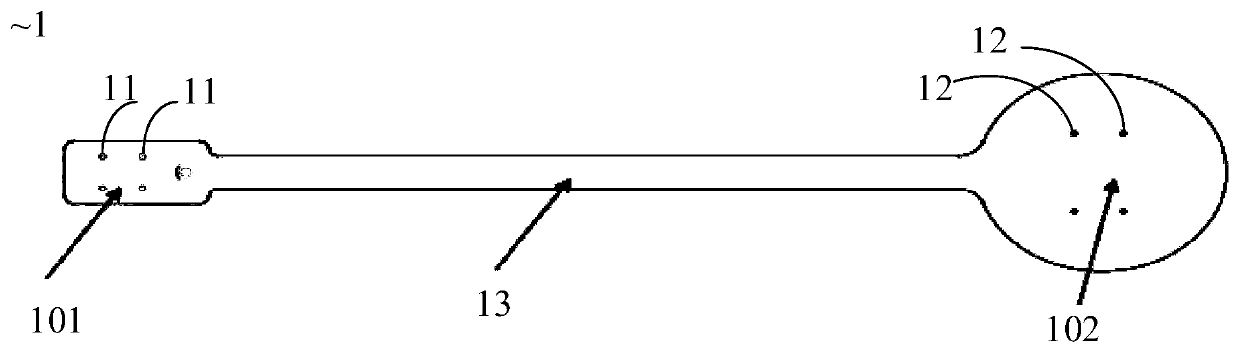

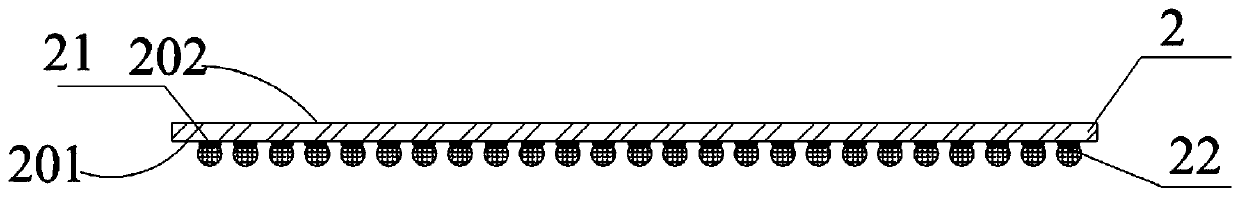

[0043] S101, see figure 2 , providing an implantable electrode 1, the electrode 1 includes a stimulating end 101 and a connecting end 102 arranged oppositely, the stimulating end 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com