Method adopting double-beam laser and TIG composite filler wire fusing-brazing for dissimilar materials

A dissimilar material and double-beam technology, applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of welding penetration, large heat input of MAG, etc., and achieve the effect of improving adaptability, improving thermal efficiency, and efficient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

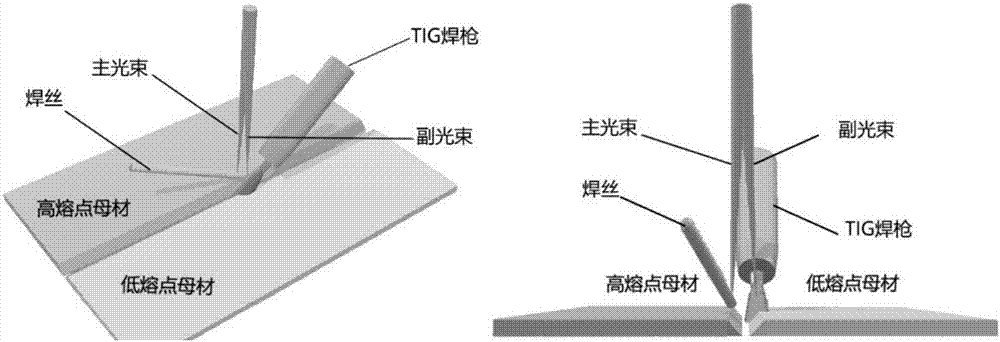

[0028] Specific implementation mode one: combine figure 1 Description of this embodiment, a dual-beam laser-TIG composite wire-filling fusion brazing method for dissimilar materials, which is carried out according to the following steps:

[0029] Step 1: Before welding, process the parts to be welded into Y-shaped grooves, I-shaped grooves or asymmetrical grooves according to the plate thickness, and grind the processed grooves and the surfaces on both sides Or cleaning, fix the workpiece to be welded after grinding or cleaning on the welding fixture;

[0030] Step 2: Use the fixture to rigidly fix the laser head, TIG welding torch and wire feeding mechanism;

[0031] Step 3: Set welding process parameters:

[0032] The laser power is 1kW~4kW, the power ratio of the two laser beams is 1:1~1:10, the defocus range is -2~+10mm, the distance between the centers of the two laser beams is 2~6mm, and Ar gas is used for protection. 15L / min~50L / min; arc current 30~90A, welding speed...

specific Embodiment approach 2

[0035] Specific implementation mode two: combination figure 1 This embodiment is described. The difference between this embodiment and the first embodiment is that the dissimilar materials are steel and non-ferrous metal dissimilar materials or dissimilar non-ferrous metal materials. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Specific implementation mode three: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is: the laser used in welding is CO 2 Gas laser, YAG solid-state laser, semiconductor laser or fiber laser. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com