Fluorgypsum light-weight laminboard

A sandwich panel and fluorogypsum technology, which is applied in building components, buildings, building structures, etc., can solve problems such as land occupation, polluted soil and groundwater environment, ecological damage, etc., to facilitate building construction and installation, and avoid wall cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

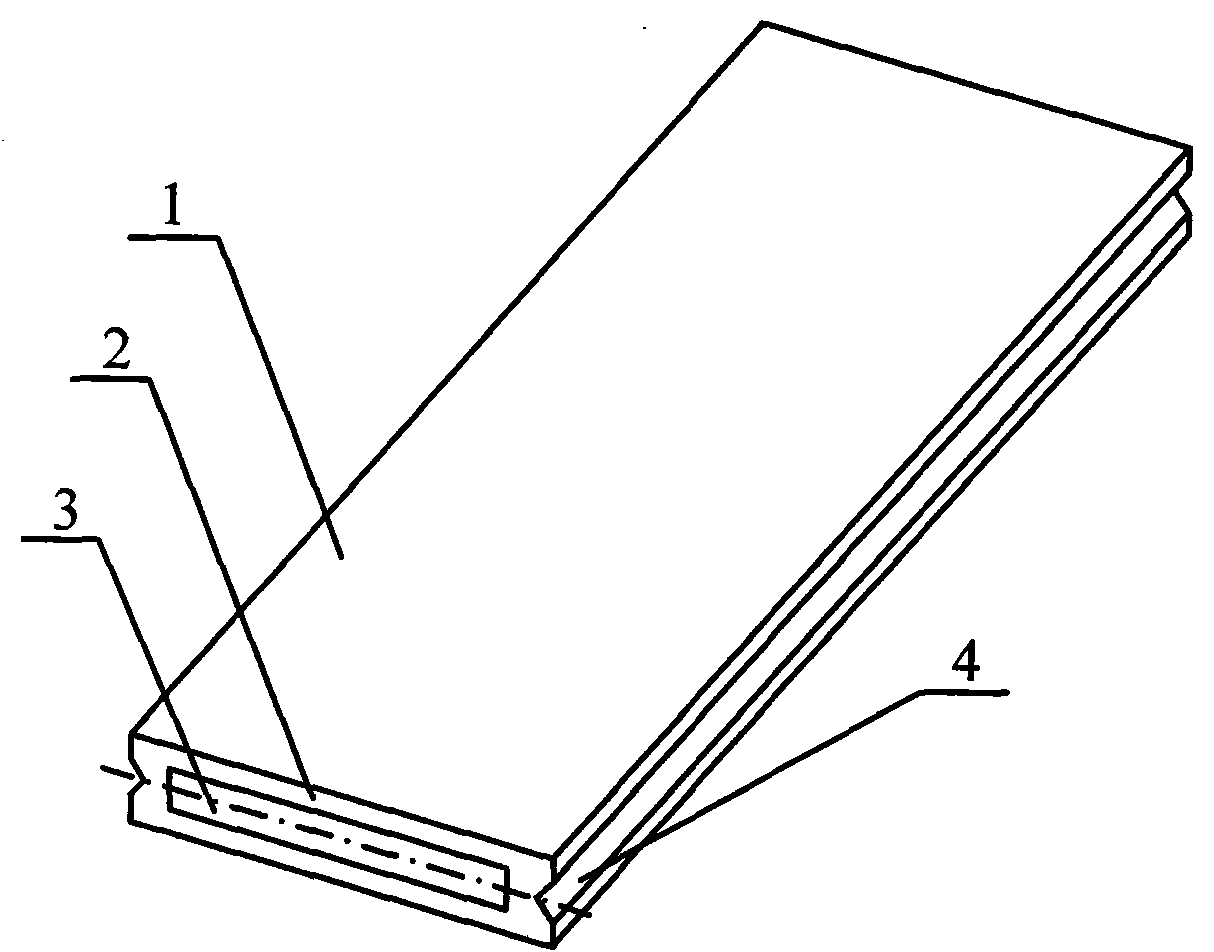

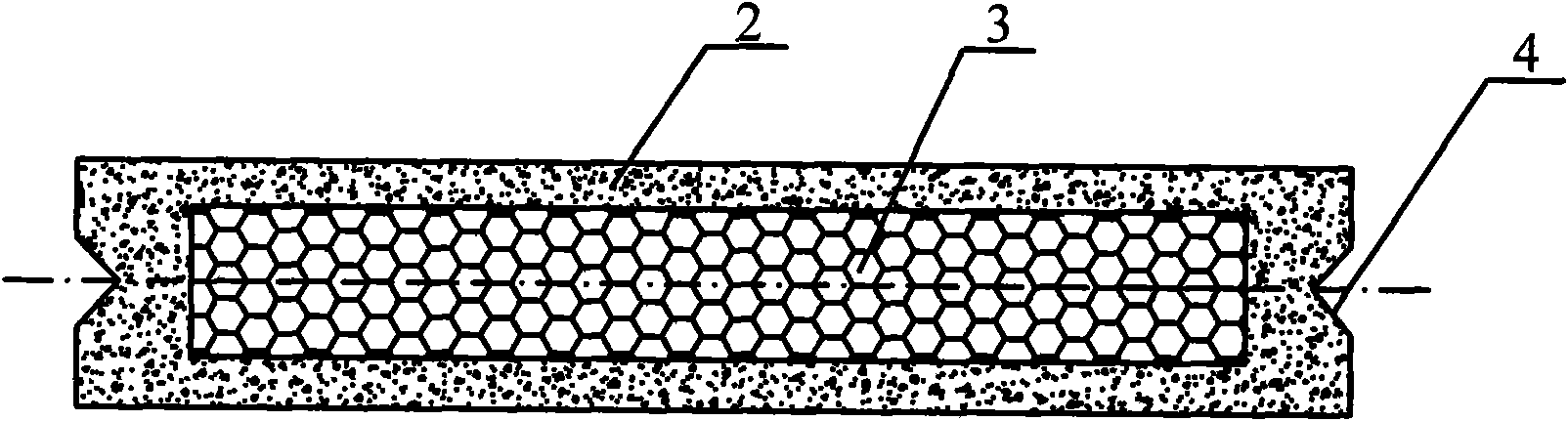

[0018] Such as figure 1 and figure 2 Shown is the structural schematic diagram and cross-sectional view of the fluorogypsum lightweight sandwich panel of the present invention. The fluorogypsum lightweight sandwich panel is made by casting the fluorogypsum slurry surface layer material 2 on the polystyrene foam board 3 , There are two lateral grooves 4 on both sides of the sandwich panel for installation and use. Grinding and calcined fluorine gypsum powder, sulphoaluminate cement, sodium sulfate, and glass fiber are used as raw materials to mix uniformly in proportion, add water and stir to form a slurry, and use abrasive tools to cast on polystyrene foam boards. After the paste is completely hardened, it is released from the mold. The fluorogypsum lightweight sandwich panel surface material of the present invention is made of the following raw materials in parts by weight:

[0019] Fluorogypsum powder 100 parts

[0020] 3 parts sulphoaluminate cement

[0021] 1 part so...

Embodiment 2

[0028] The sandwich panel of the present embodiment is basically the same as the first embodiment, and its raw material ratio is:

[0029] Fluorogypsum powder 100 parts

[0030] 4 parts sulphoaluminate cement

[0032] 0.9 parts of glass fiber

[0033] Water to material ratio 0.8

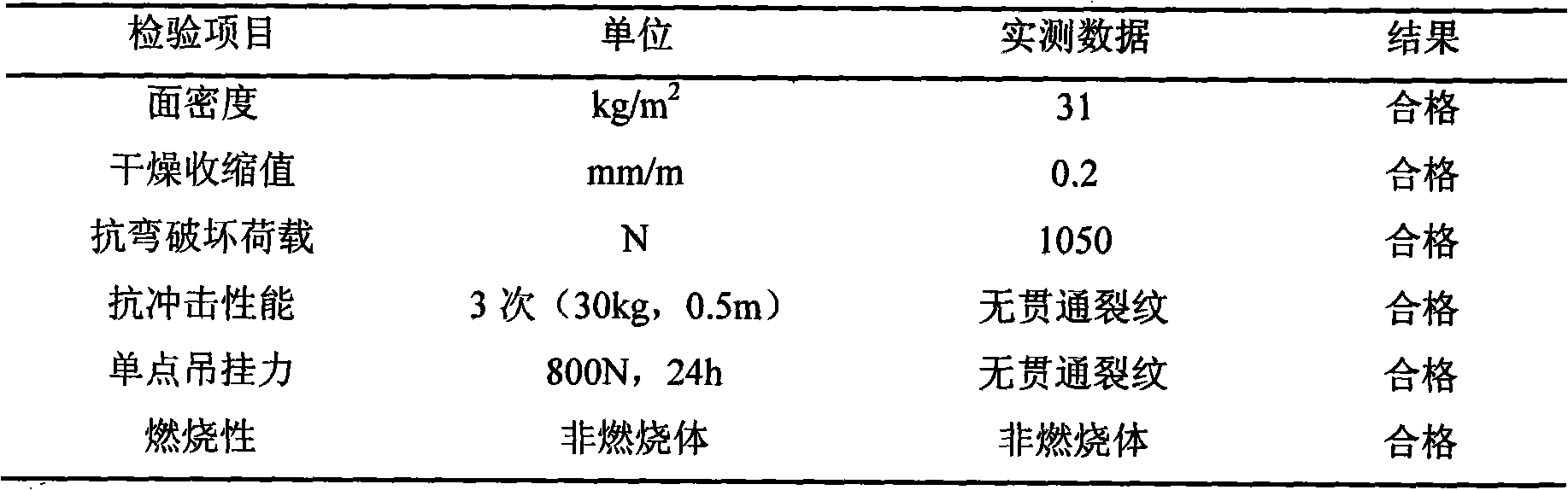

[0034] The size of the fluorogypsum lightweight sandwich panel produced is 3000mm×600mm×90mm, and the technical performance test results are shown in Table 2.

[0035] Table 2

[0036]

Embodiment 3

[0038] The sandwich panel of the present embodiment is basically the same as the first embodiment, and its raw material ratio is:

[0039] Fluorogypsum powder 100 parts

[0040] 6 parts of sulphoaluminate cement

[0042] 1.2 parts of glass fiber

[0043] Water to material ratio 0.9

[0044] The size of the fluorogypsum lightweight sandwich panel produced is 2500mm×600mm×120mm, and the technical performance test results are shown in Table 3.

[0045] table 3

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com