Highly-thermoplastic high-manganese and high-aluminum TWIP steel and production method thereof

A production method and high-manganese technology, applied in the field of high-manganese and high-aluminum TWIP steel, can solve the problems that cannot directly guide the improvement of high-manganese and high-aluminum TWIP steel thermoplasticity, low yield, poor effect stability, etc., to achieve improved thermoplasticity, high Surface quality, effect of reducing precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in combination with specific embodiments.

[0019] The high thermoplastic high manganese and high aluminum TWIP steel adopts the following production methods: (1) Ingredients: According to the elemental composition of the target steel grade, it is equipped with industrial pure iron, industrial silicon, carbon powder, electrolytic manganese, electrolytic aluminum, and ferroniobium and / or molybdenum strips.

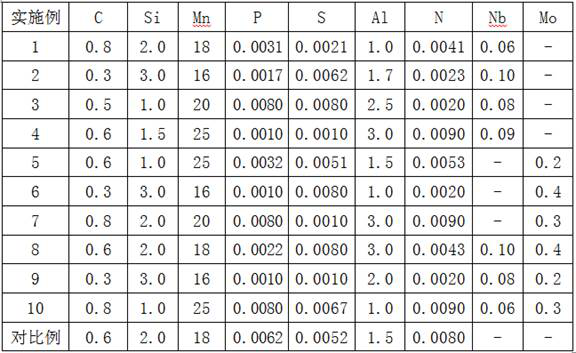

[0020] The mass percentages of the chemical components of the high manganese and high aluminum TWIP steel grades are: C 0.3%-0.8%, Si 1%-3%, Mn 16%-25%, P 0.001%-0.008%, S 0.001 %~0.008%, Al 1%~3%, N 0.002%~0.009%, Nb 0.06%~0.1% and / or Mo 0.2%~0.4%, the balance is iron Fe and other unavoidable trace elements.

[0021] (2) Melting: put industrial pure iron, industrial silicon, carbon powder and electrolytic manganese into the crucible of the vacuum induction furnace, evacuate the vacuum induction furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com