Bearing static stiffness test device and test method thereof

A test device and static stiffness technology, applied in the direction of mechanical bearing testing, measuring devices, electromagnetic measuring devices, etc., can solve the problems of inability to obtain bearing stiffness characteristics, bearing stiffness test devices and test methods, etc., and achieve simple structure and simple method Lines and parameters are accurate and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with accompanying drawing.

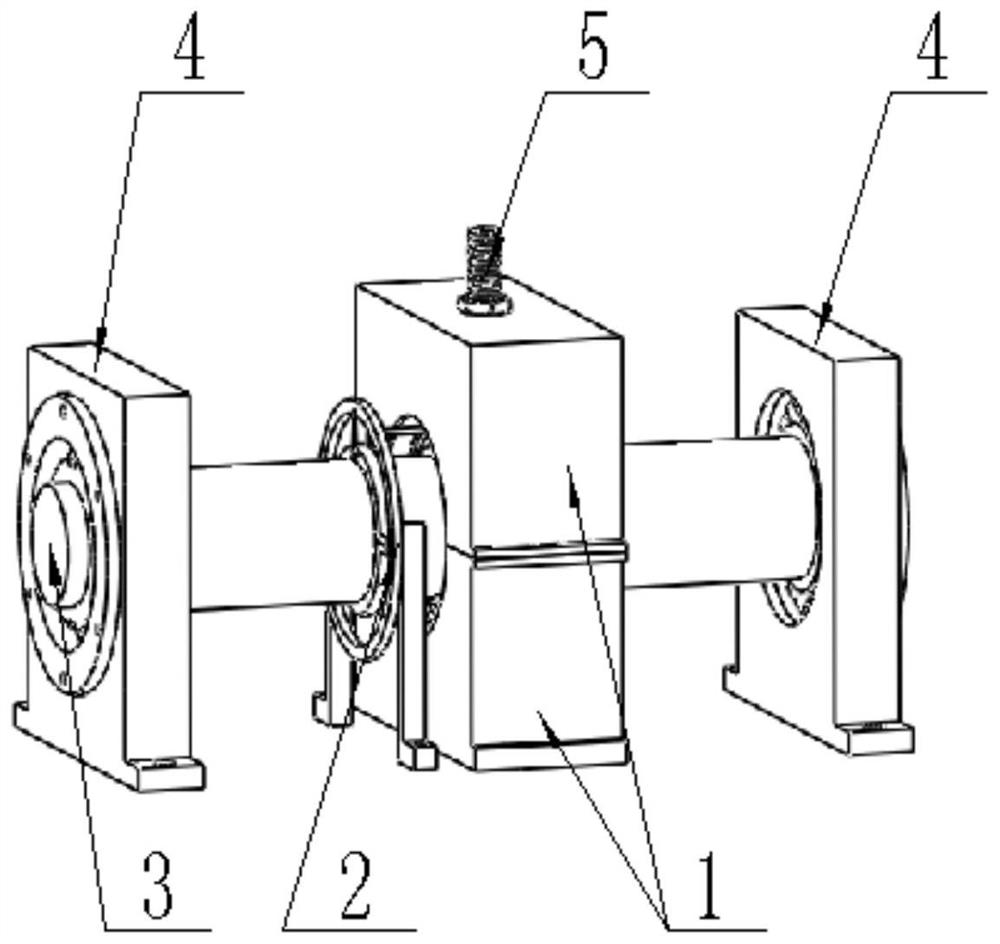

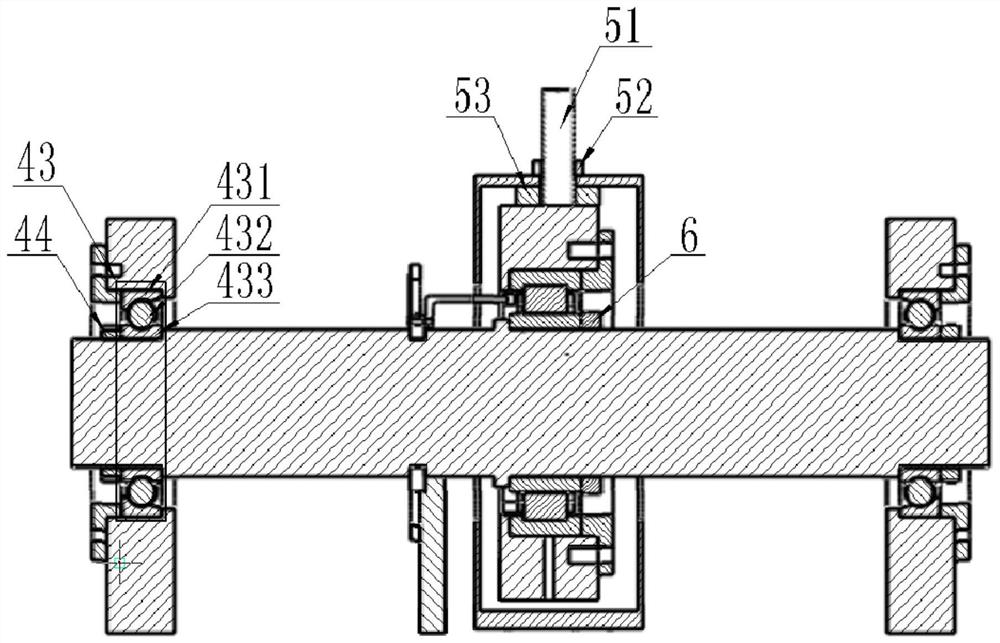

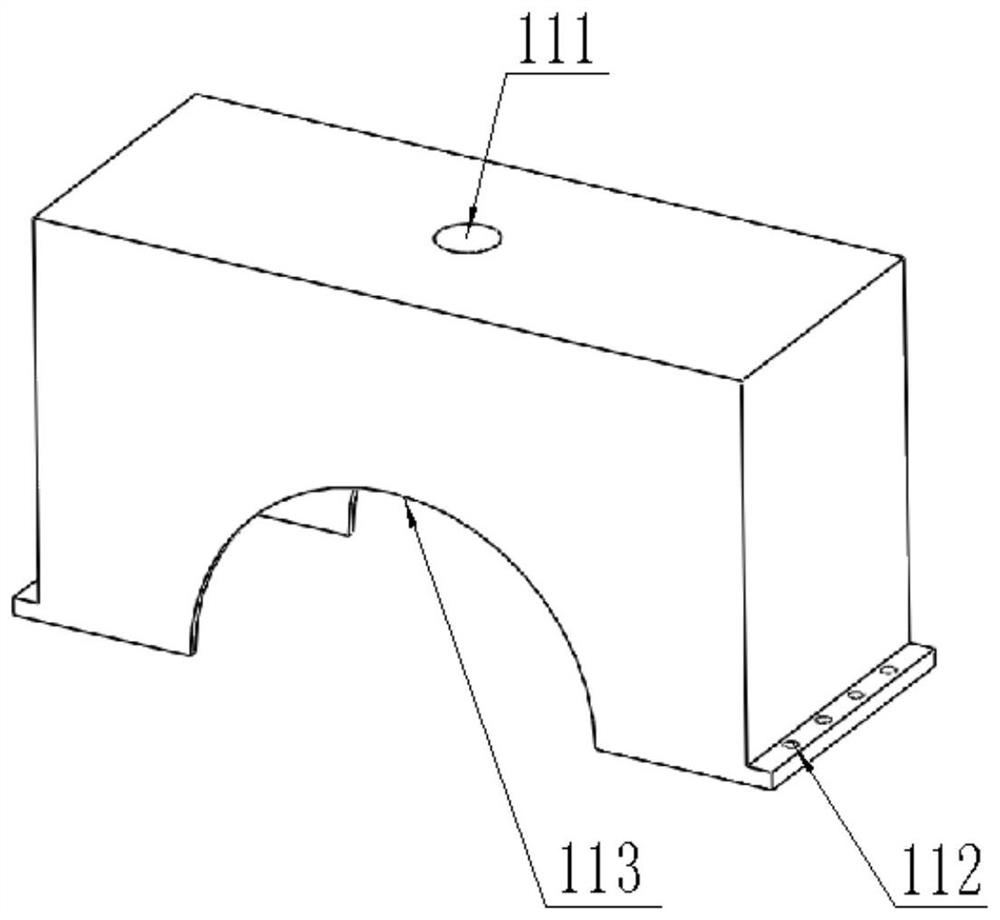

[0057] figure 1 It is the overall schematic diagram of the bearing static stiffness test device in the embodiment of the present invention, figure 2 its section view. see figure 1 with figure 2 , In this embodiment, the bearing static stiffness test device includes a test box 1, a variable cage angle device 2, a spindle 3, a support system 4, a loading system 5, a lock nut 6, a bearing seat b8 and a sensor system 9. When the test box 1 is in use, the outer ring 72 of the tested bearing 7 is placed in the tested bearing seat 8, and the bearing gland 81 and the bearing seat 8 are fixedly connected by bolts, and the bearing gland 81 fixes the outer ring 72 of the tested bearing 7 , the inner ring 74 is set on the main shaft 3 and fixed axially by the shaft shoulder b32 and the lock nut 6; the lock nut 6 is screwed into the main shaft 3 to fix the inner ring 74 of the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com