Real-time prediction method and system for shield tunneling machine cutterhead torque

A technology of cutter head torque and real-time prediction, applied in instrument, geometric CAD, design optimization/simulation, etc., can solve problems such as endangering personal safety, safety accidents, economic losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Aiming at the problems of low prediction accuracy and weak generalization ability existing in the current cutterhead torque prediction method, the present invention provides a real-time cutterhead torque prediction method based on residual CNN-LSTM neural network.

[0088] A method for real-time prediction of cutter head torque of a shield machine according to the present invention includes:

[0089] Step M1: Select the operating parameters of the shield machine that affect the torque of the cutter head during the actual working process of the shield machine and meet the preset requirements; including jack propulsion speed, geological pressure on the shield machine, cutter head thrust, cutter head speed, shield machine The force of the engine propulsion system, the current and frequency of the propulsion motor, etc.

[0090] Step M2: Preprocessing the operating parameters of the shield machine that meet the preset requirements;

[0091] Step M3: Based on the CNN neural...

Embodiment 2

[0171] Embodiment 2 is a modification of embodiment 1

[0172] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0173] refer to Figure 1 to Figure 9 , a method for real-time prediction of cutter head torque based on residual CNN-LSTM neural network, including the following steps:

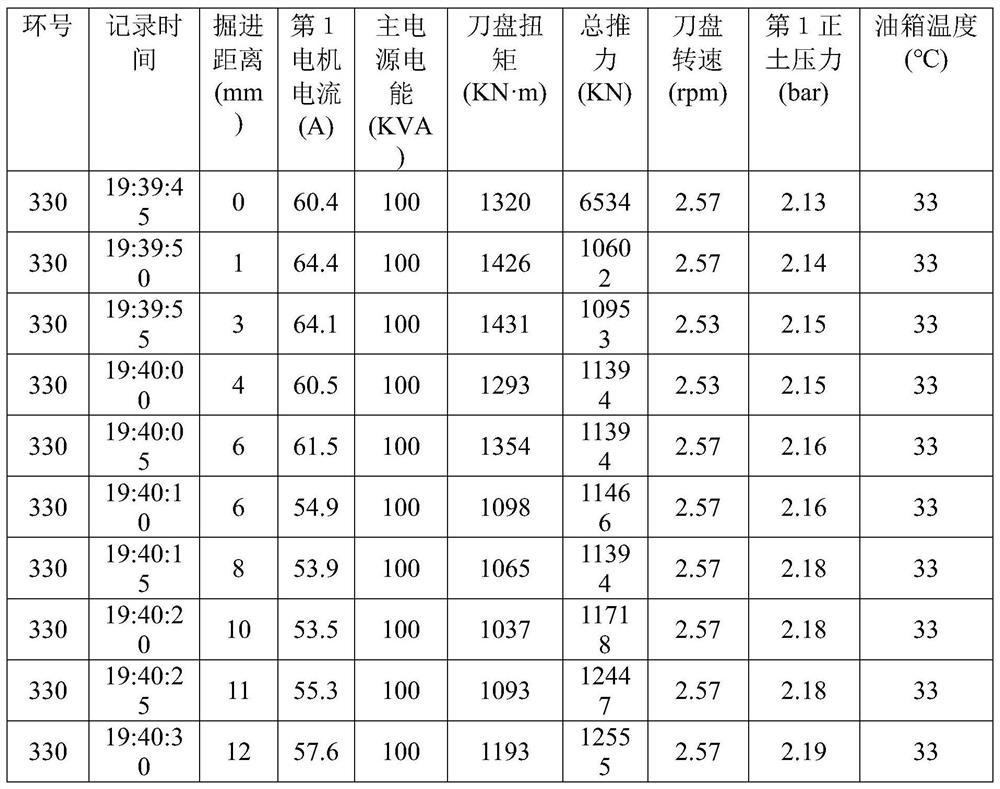

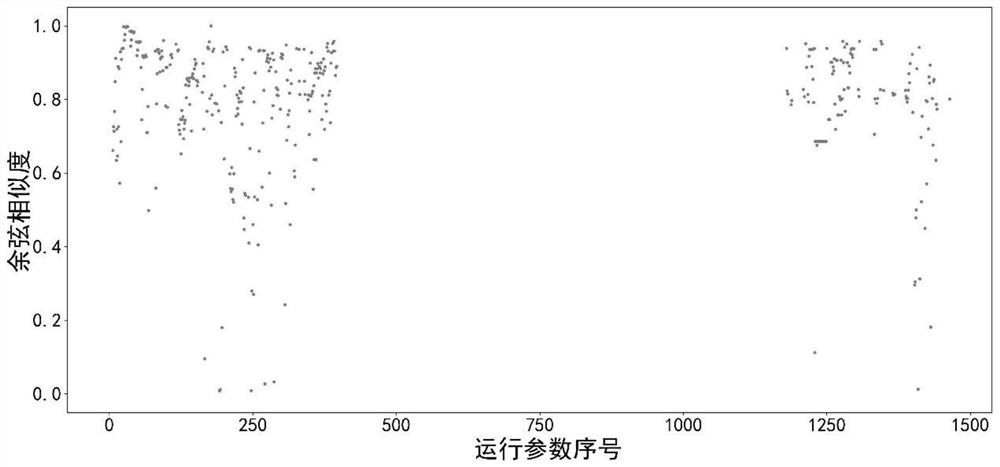

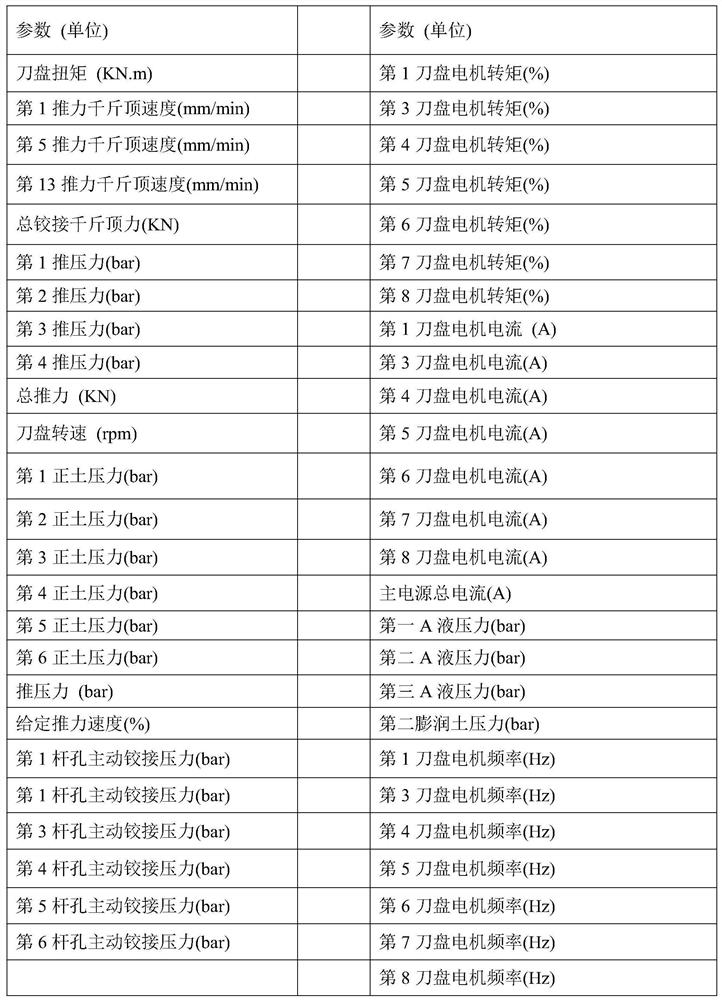

[0174] Step 1: Select the key parameters, and select the operating parameters of the shield machine that have a greater impact on the cutter head torque during the actual working process of the shield machine as the input of the prediction model. figure 1 It is the database diagram of the operating parameters of the actual construction of the shield machine, figure 2 It is the cosine similarity diagram between the operating parameters of the shield machine and the cutter head torque in the database, and the operating parameters of the shield machine whose cosine similarity with the cutter head torque is greater than 0.85 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com