Mine Fault Structure Prediction Method

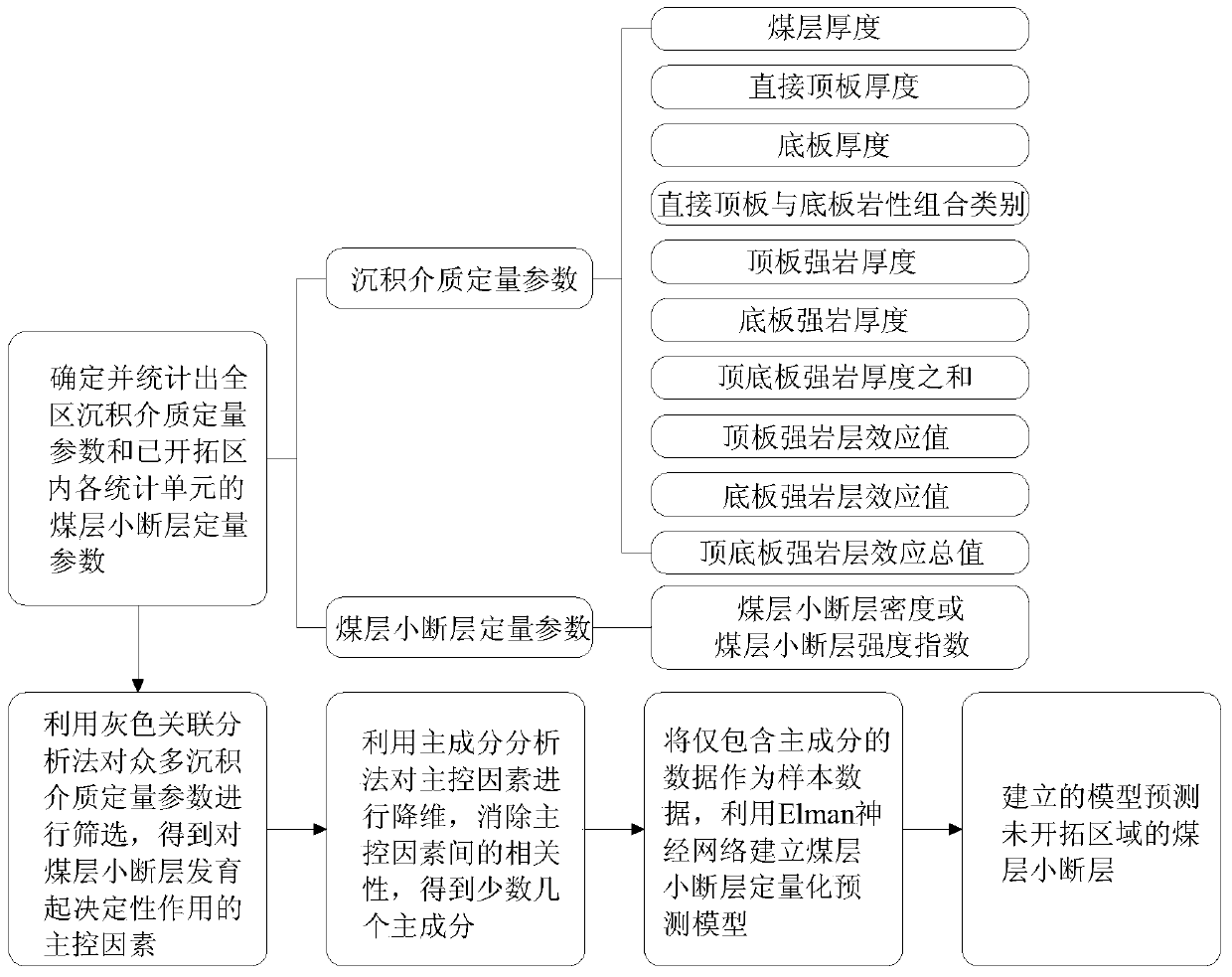

A prediction method and fault technology, applied in the fields of instrumentation, calculation, electrical and digital data processing, etc., can solve the problem of not quantitatively predicting the development degree of small faults, and achieve the effects of reducing input dimensions, fast learning speed, and easy parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

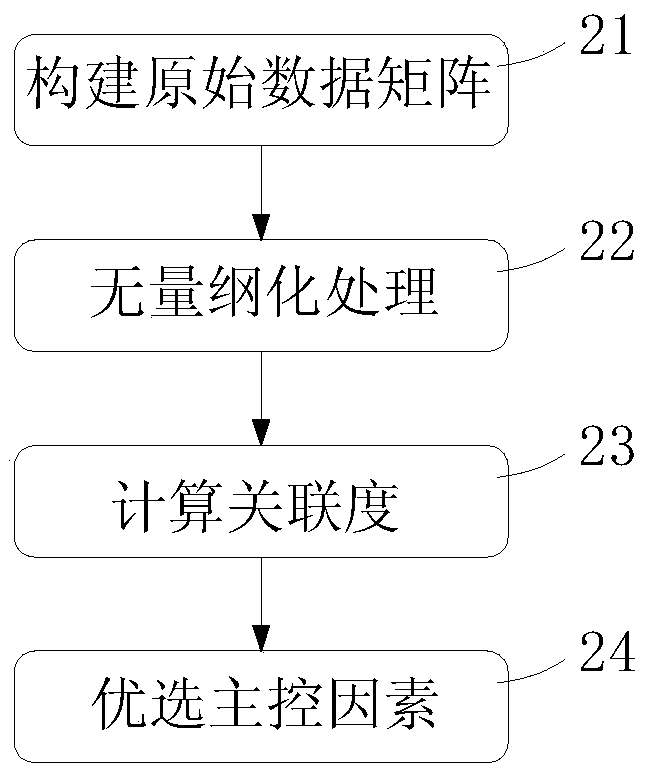

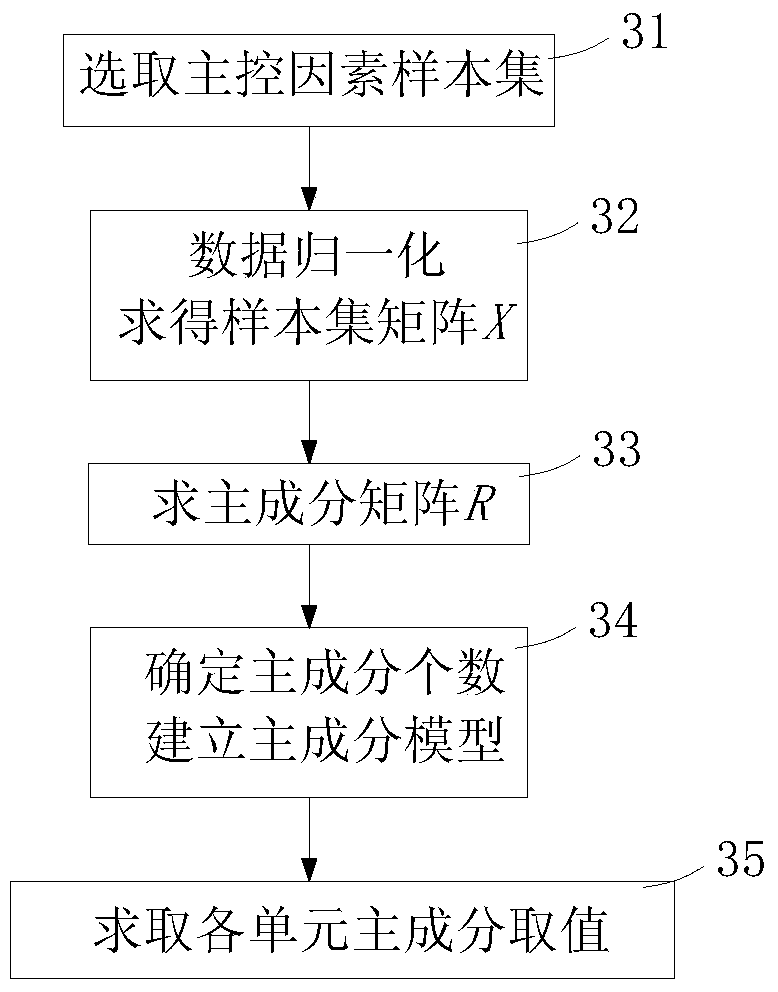

Method used

Image

Examples

Embodiment

[0084] Embodiment: The prediction object is a small fault in the 7th coal seam of a certain coal mine, and the prediction steps are as described above.

[0085] The specific prediction process and results are as follows:

[0086] (1) Determine and count the quantitative parameters of the sedimentary medium of the whole area (including the developed area and the undeveloped area) and the quantitative parameters of the small coal seam faults of each statistical unit in the developed area.

[0087] According to the difficulty of fault index statistics and the actual situation of the mine, the quantitative parameters of small coal seam faults in the 7th coal seam are used to select the density of small coal seam faults; on the mining engineering plan, the developed area is divided into 30 statistical units according to the grid of 300m×300m, Statistically calculate the coal seam small fault density in each unit in the mined area, and draw the thematic map ( Figure 4 ). The qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com