Aging accelerating device for perfume processing

A perfume and aging technology, which is applied in the fields of control/regulating process, chemical/physical/physical chemical process, chemical instruments and methods, etc., can solve the problems of limited, single action direction and scope of aging components, etc., to improve the mixing ratio. effect, the effect of increasing the effective working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

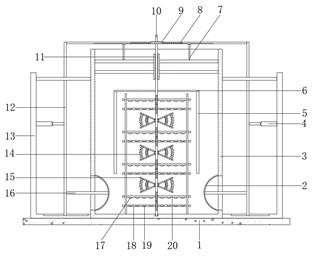

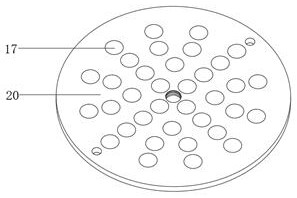

[0030] refer to Figure 1-4 , an aging device for perfume processing, comprising a base 1, the top outer wall of the base 1 is fixed with an aging tank 3 by bolts, both sides of the bottom of the aging tank 3 are provided with installation ports, and the inner walls of the installation ports are fixed An elastic membrane body 2 is installed, and the inner wall of the aging tank 3 near the top is welded horizontally with poles, and the ends of the poles are welded with the same fixed cylinder 11, and the fixed cylinder 11 passes through the opposite side of the aging tank 3. The bearing is rotatably connected to the same rotating rod 10, and the rotating rod 10 is provided with threaded end 1 24 and threaded end 2 25 distributed equidistantly, the thread directions of threaded end 1 24 and threaded end 2 25 are opposite, and threaded end 24 The upper end plate 20 and the lower end plate 18 are respectively threadedly connected with the threaded end two 25, and the opposite side...

Embodiment 2

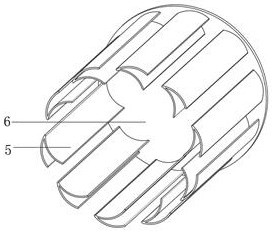

[0041] refer to Figure 5 , a perfume aging device. Compared with Embodiment 1, this embodiment also includes that the outer wall of the corner plate 5 is provided with a protruding component 26, and the protruding component 26 includes an oblique shape welded to the outer wall of the corner plate 5. The corner piece 27 and the bottom end of the oblique angle piece 27 are welded with a curved plate 28, and the oblique angle piece 27 and the curved plate 28 are distributed in a spiral shape as a whole.

[0042] When the present invention is in use: the protruding component 26 arranged on the outer wall of the corner plate 5 can be used, and the oblique corner piece 27 and the curved plate 28 can be used to stir and vertically rotate the liquid material during the back and forth rotation of the corner plate 5. The driving force is to achieve the purpose of improving the aging effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com