Separation device for removing impurities from vegetable peels

A separation device and peel technology, which are applied to the removal of solid waste, the cleaning method using tools, the cleaning method using liquid, etc., can solve the problems of waste of resources, low efficiency, difficulty in separating vegetable peels, etc., to save resources, protect The effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

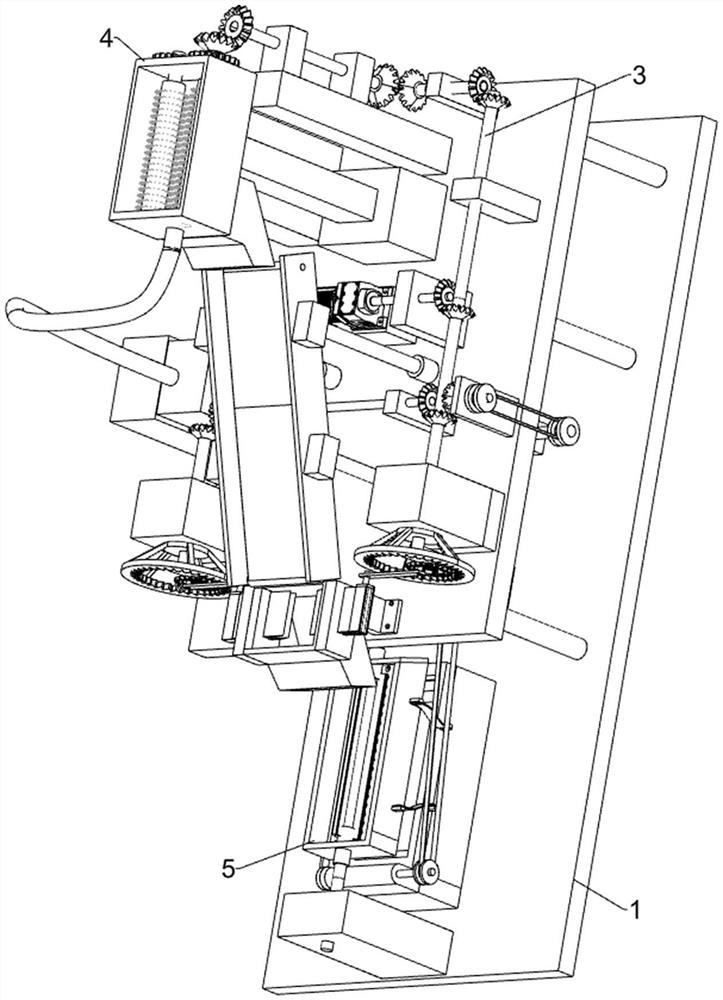

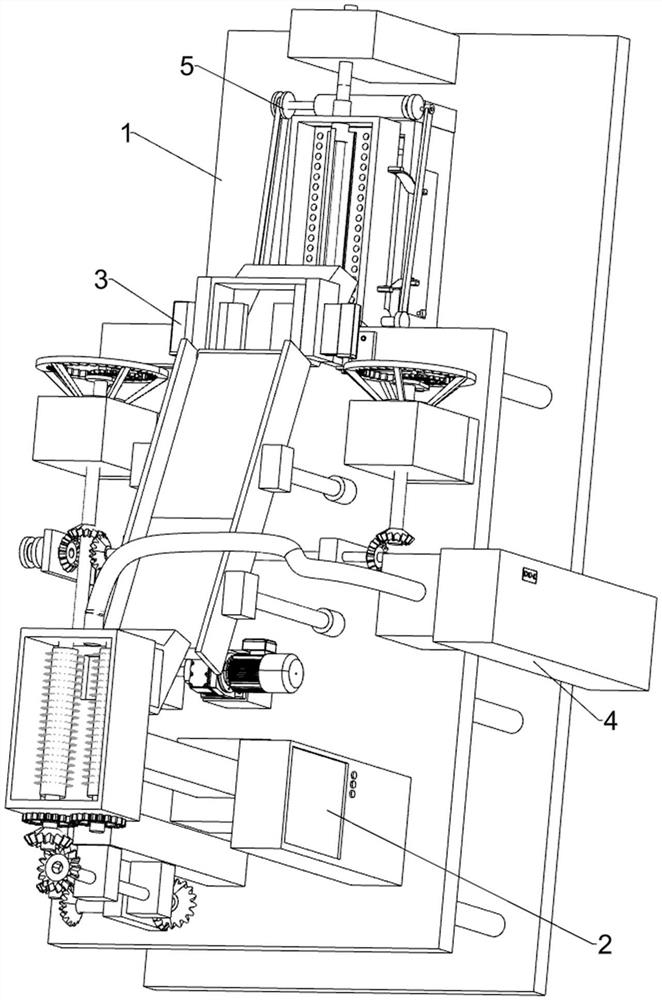

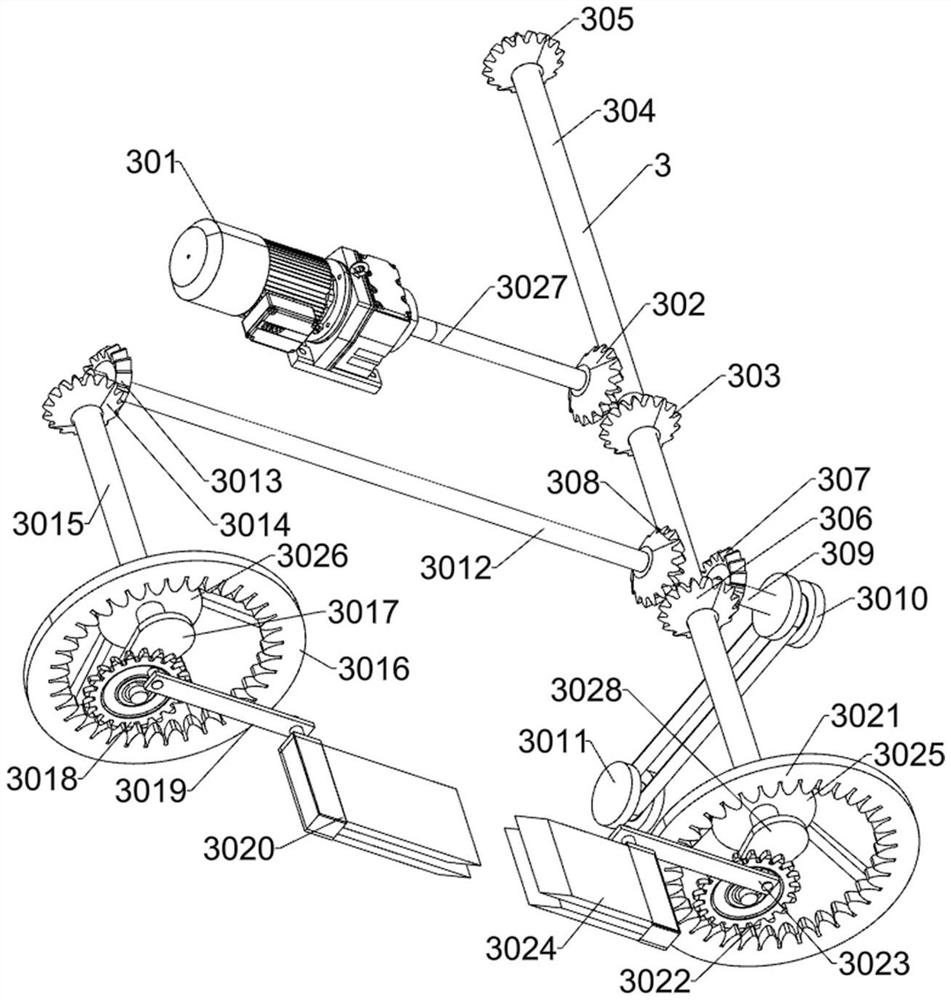

[0024] A separation device for removing impurities from vegetable peels, such as Figure 1-5 As shown, it includes worktable, control panel, cutting mechanism, cleaning mechanism and separation mechanism; the workbench is connected with the control panel; the workbench is connected with the cutting mechanism; the workbench is connected with the cleaning mechanism; the workbench is connected with the separation mechanism connection; the cutting mechanism is connected with the cleaning mechanism; the cutting mechanism is connected with the separation mechanism.

[0025]Working principle: When the device is used, first open and adjust the device through the control panel, then manually put the vegetable peel containing plastic bags and soil into the cleaning mechanism, and then clean the surface soil through the cleaning mechanism, and then slide it through the workbench. into the cutting mechanism, the plastic bag mixed with it is chopped by the cutting mechanism, and finally th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com