Metal recovery device based on heating separation principle

A recycling device and separation principle technology, applied in the direction of improving process efficiency, can solve problems such as bacterial infection, environmental impact, hand injury, etc., to achieve the effect of improving recycling efficiency and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

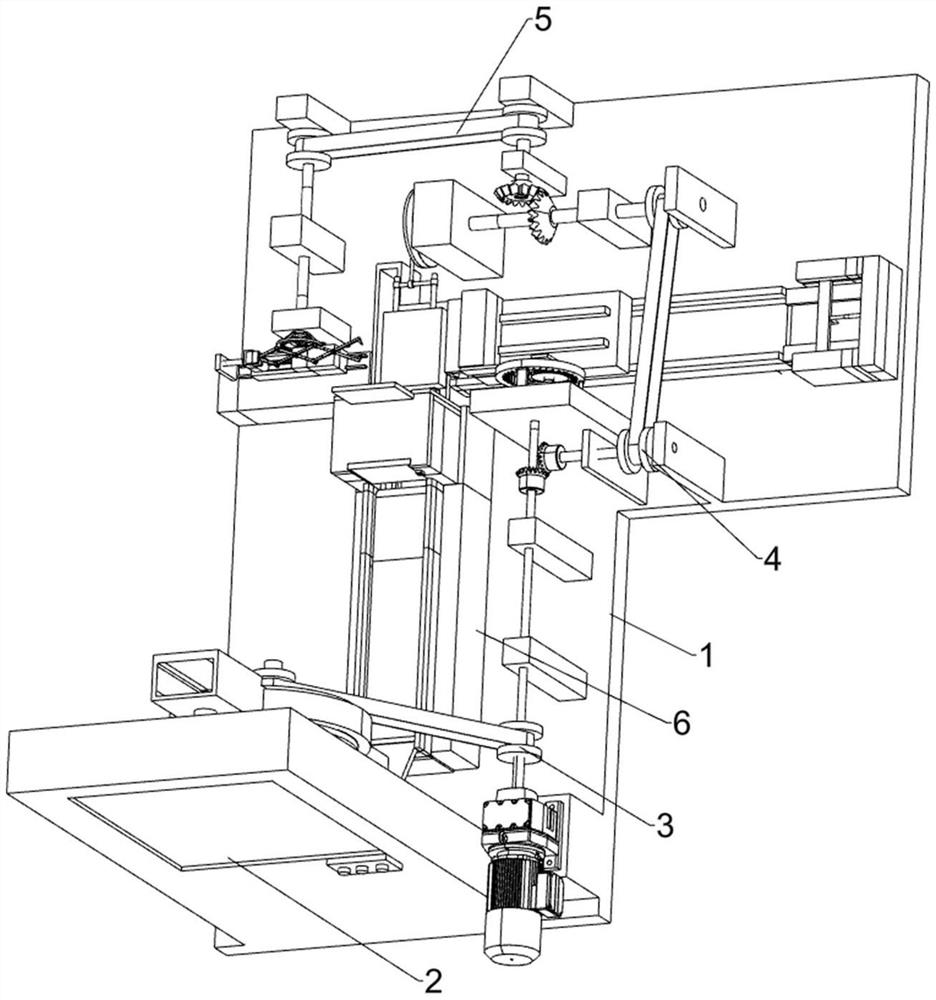

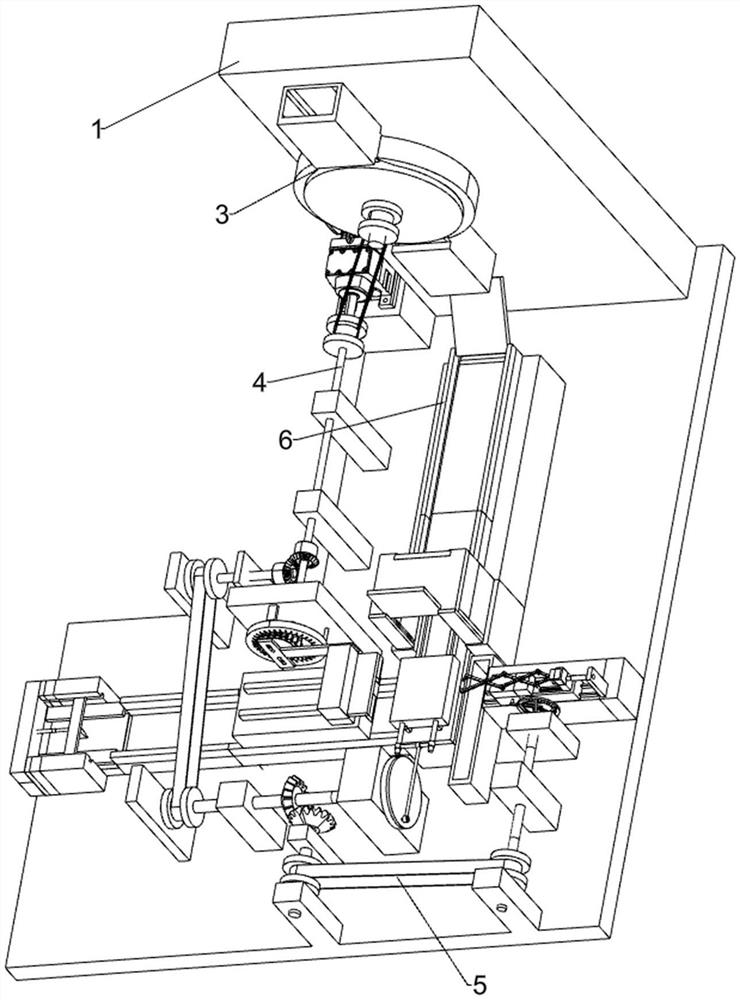

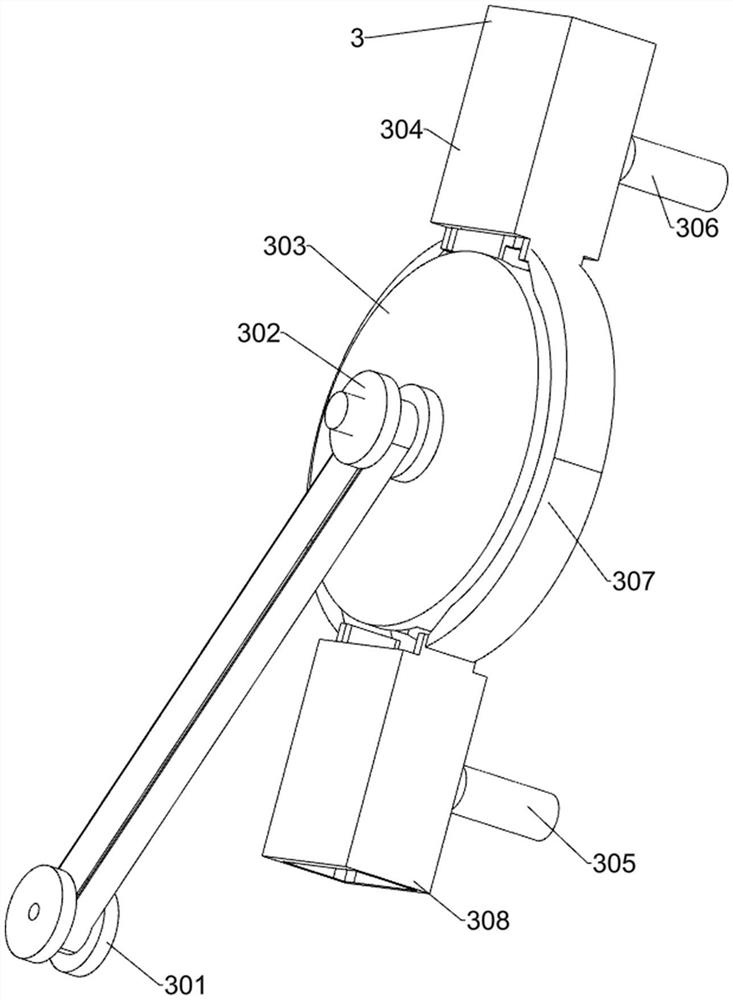

[0025] A metal recovery device based on the principle of heating separation, such as Figure 1-6 As shown, it includes a workbench, a control panel, a feeding mechanism, a fixing mechanism, a separation mechanism and a heating and cutting mechanism; the workbench is connected to the control panel; the workbench is connected to the feeding mechanism; the workbench is connected to the fixing mechanism; The workbench is connected with the separation mechanism; the workbench is connected with the heating and cutting mechanism; the feeding mechanism is connected with the fixing mechanism; the fixing mechanism is connected with the separation mechanism; the fixing mechanism is connected with the heating and cutting mechanism; connect.

[0026]When the device is in use, first open and adjust the device through the control panel, then manually put the aluminum foil bag into the feeding mechanism on the workbench, and intermittently feed it through the feeding mechanism, and then heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com