An integrated device for an assembled fence

An integrated device and assembled technology, applied in the field of integrated devices for assembled enclosures, can solve the problems of increasing the defect rate, large deviation of the welding position of the baffle and the column, and the product size cannot meet the requirements, so as to save labor costs, The effect of improving production efficiency and precise product location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

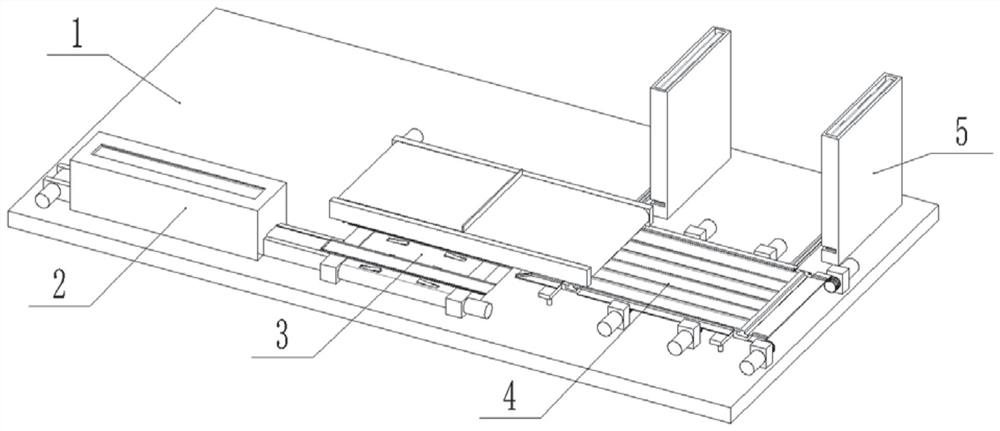

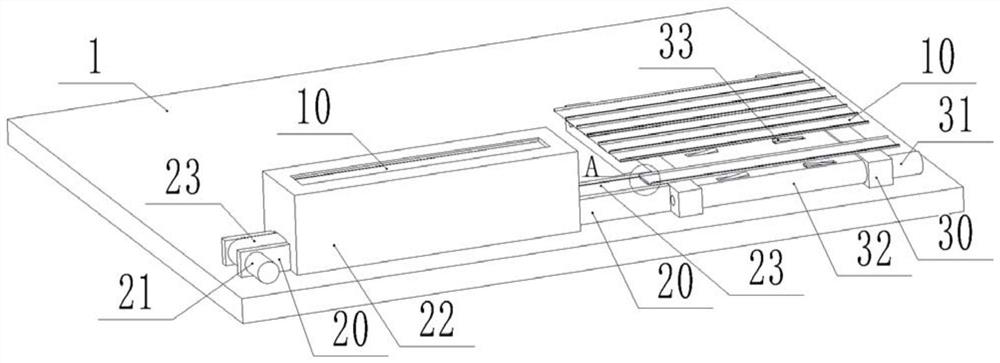

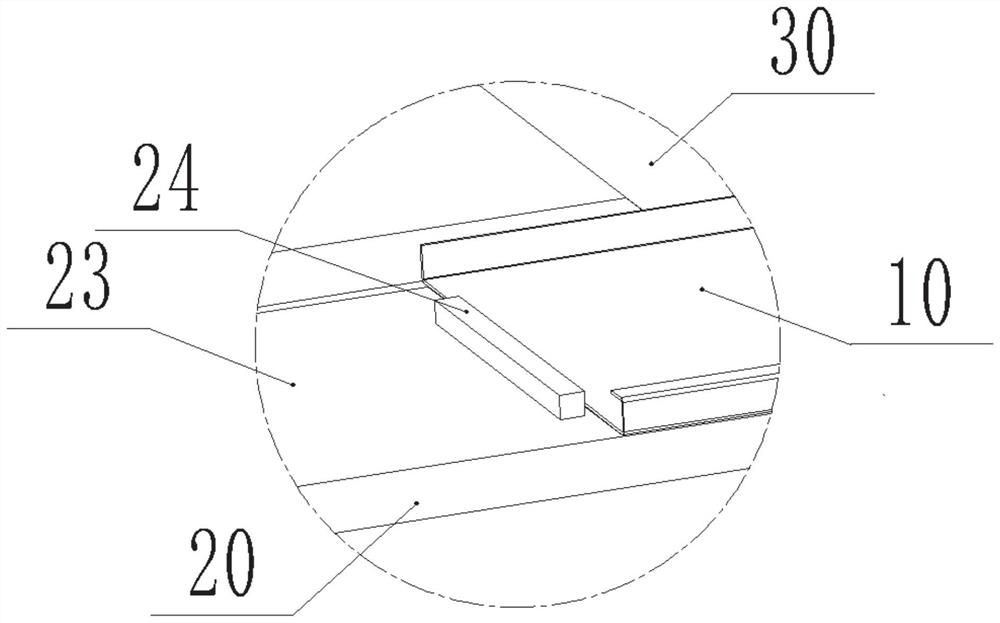

[0044] Such as Figure 1-16 As shown, an integrated device for an assembled fence provided in this embodiment, the assembled fence includes a baffle 10 and a column 11, and the two sides of the baffle 10 are vertically connected with the column 11, and the baffle 10 The number of 10 is multiple, and a plurality of said baffle plates 10 are arranged side by side; said integrated device for the assembled enclosure includes:

[0045] work platform 1;

[0046] Baffle plate storage and conveyance mechanism 2, said baffle plate storage and conveyance mechanism 2 is installed on said working platform 1, and is used for storage and conveyance of baffle plate 10;

[0047] A side-by-side integration mechanism 3 for side-by-side baffle plates. The side-by-side integration mechanism 3 is installed on the working platform 1 and used to integrate more than 10 baffle plates transported by the baffle plate storage and conveying mechanism 2 side by side to form a baffle plate. board group; ...

Embodiment 2

[0064] In this embodiment, the assembled fence also includes a bottom plate 12, and one end of the two columns 11 is connected to the bottom plate 12. Embodiment 2 is further compared to Embodiment 1. The assembled fence is integrated The device also includes:

[0065] Bottom plate conveying mechanism 9, described bottom plate conveying mechanism 9 is installed on the described working platform 1, and is used for the conveying of bottom plate 12, and described bottom plate conveying mechanism 9 conveys described bottom plate 12 to the described general integration mechanism 4, and two One end of the column 11 has the bottom plate 12 .

[0066] The assembly device for the prefabricated fence of the second embodiment can effectively integrate the baffle group, the column 11 and the bottom plate 12 automatically, further improving the production efficiency of the prefabricated fence and saving labor costs. After the automatic integration of multiple baffles 10, two columns 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com