A clamping device and method for improving the machining quality of radial holes of airfoil parts

A technology of processing quality and clamping device, which is applied in the direction of positioning device, metal processing equipment, metal processing machinery parts, etc., can solve the problems of easy deformation of two wings, poor structural rigidity, and excessive parallelism, so as to save clamping time , reduce processing costs, and produce simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

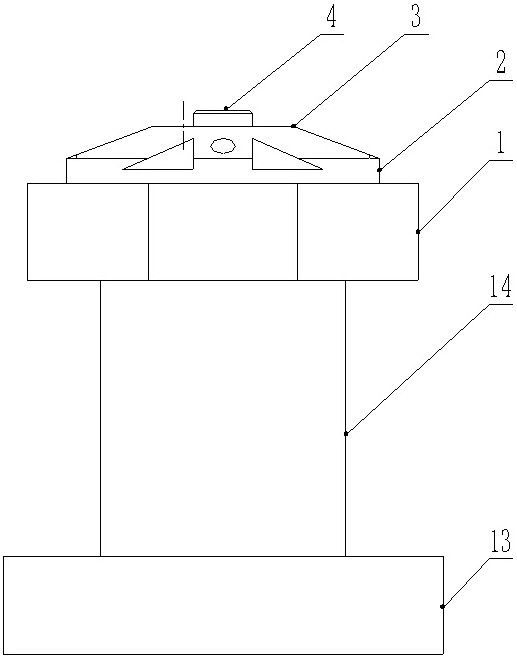

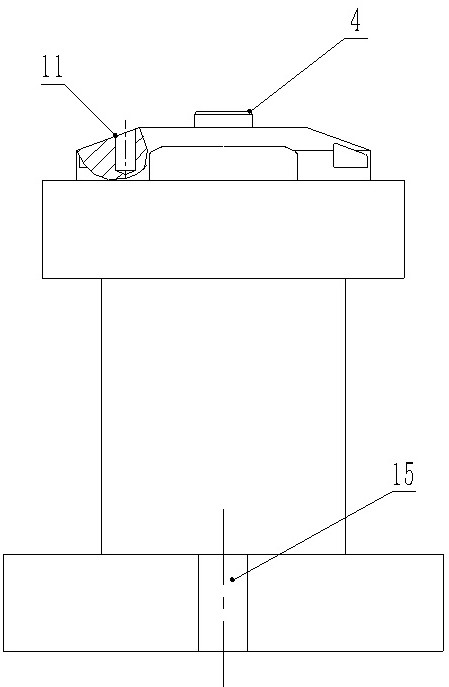

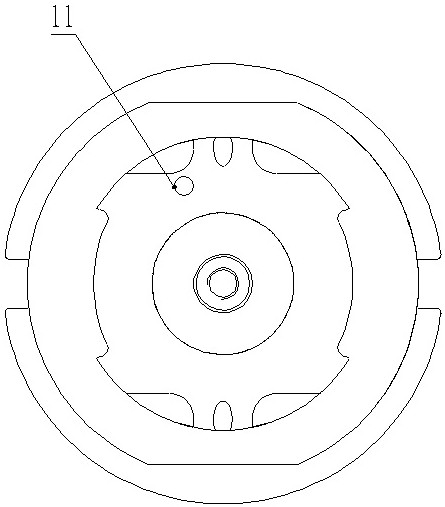

[0048] This embodiment relates to a clamping device for improving the machining quality of radial holes of airfoil parts, such as figure 1 As shown, it includes a first member 1 with at least one plane, the plane of the first member 1 extends vertically upwards to form a cylindrical second member 2, and the upper cylindrical surface of the second member 2 extends upwards to form a third member 3 in the shape of a cone. The center of the third component 3 is provided with a positioning mandrel 4 for the target airfoil part 5 to pass through, and the two wings of the target airfoil part 5 are attached to the annular curved surface of the third component 3 and the circumferential surface of the second component 2;

[0049]The upper cylindrical surface of the third member 3 is used as the micro-deformation control surface 20 , and the annular curved surface of the third member 3 is used as the auxiliary positioning taper surface 21 .

[0050] The clamping device provided in this e...

no. 2 approach

[0056] This embodiment relates to a clamping device for improving the machining quality of radial holes of airfoil parts, such as figure 1 , figure 2 with image 3 As shown, it includes a first member 1 with at least one plane, the plane of the first member 1 extends vertically upwards to form a cylindrical second member 2, and the upper cylindrical surface of the second member 2 extends upwards to form a third member 3 in the shape of a cone. The center of the third component 3 is provided with a positioning mandrel 4 for the target airfoil part 5 to go through, and the two wings of the target airfoil part 5 are attached to the annular curved surface of the third component 3 and the circumferential surface of the second component 2; wherein The upper cylindrical surface of the third member 3 serves as the micro-deformation control surface 20 , and the annular curved surface of the third member 3 serves as the auxiliary positioning taper surface 21 .

[0057] see figure 1 ...

no. 3 approach

[0073] This embodiment provides a clamping method for improving the machining quality of radial holes of airfoil parts, including a clamping device for improving the machining quality of radial holes of airfoil parts. The clamping method is as follows:

[0074] Pass the central positioning hole 19 of the target airfoil part 5 through the positioning mandrel 4, rotate the target airfoil part 5 until its two wings fit the annular curved surface of the third member 3 and the circumferential surface of the second member 2, and fix the target airfoil Part 5 , process target radial holes 12 on both wings of the target airfoil part 5 .

[0075] The clamping device includes a first member 1 with at least one plane, the plane of the first member 1 extends vertically upwards to form a cylindrical second member 2, and the upper cylindrical surface of the second member 2 extends upwards to form a conical third member 3 , the center of the third member 3 is provided with a positioning mand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com